Synthesis method of flexible-foam flame-retardant polyether polyol

A technology of flame retardant polyether and synthesis method, which is applied in the synthesis field of flexible foam flame retardant polyether polyol, can solve the problems such as the decline of the physical and mechanical properties of foam collapsed foam, the insignificant flame retardant effect of flame retardants, and the loss of performance advantages. , to achieve the effect of high oxygen index, small physical and mechanical properties, and easy foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

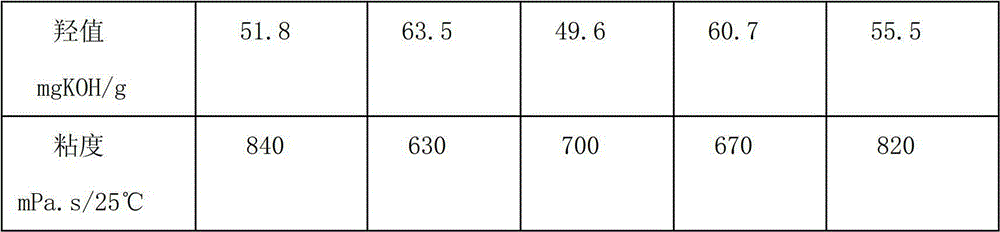

Embodiment 1

[0025] Add 126g of melamine and 244g of formaldehyde solution with a mass fraction of 37% into a 5L stainless steel reaction kettle, pump in 5g of diethanolamine, react at 70°C for 3h, and obtain 216g of melamine-formaldehyde condensate; add 62g of ethylene glycol, and continue the reaction for 1h Finally, it was dehydrated under reduced pressure at 70°C to a moisture content of 5%. Raise the temperature to 80°C, start adding propylene oxide, keep the pressure in the kettle at 0.1-0.4MPa, and the temperature is 80-100°C, continuously add 716g of propylene oxide. Unreacted propylene oxide and water can obtain high hydroxyl value polyether with moisture content ≤ 0.01%, and its hydroxyl value is 426mgKOH / g.

[0026] Add 5.2g KOH to the reaction kettle, raise the temperature to 110°C, start adding propylene oxide, and continuously add 1570g propylene oxide to react to obtain crude polyether, which is neutralized and refined to obtain soft foam flame-retardant polyether polyol. T...

Embodiment 2

[0028] Add 126g of melamine and 244g of formaldehyde solution with a mass fraction of 37% into a 5L stainless steel reaction kettle, pump in 5g of tertiary amine, react at 70°C for 3h, and obtain 216g of melamine-formaldehyde condensate; add 134g of dipropylene glycol, and continue the reaction for 1h , Dehydration under reduced pressure at 70°C to a moisture content of 5%. Raise the temperature to 80°C, start to add ethylene oxide, keep the pressure in the kettle at 0.1-0.4MPa, and keep the temperature at 80-100°C, continuously add 396g of ethylene oxide. Press to remove unreacted ethylene oxide and water to obtain a high hydroxyl value polyether with a moisture content of ≤0.01%, and its hydroxyl value is 492 mgKOH / g.

[0029] Add 4.8g NaOH to the reaction kettle, raise the temperature to 110°C, start adding ethylene oxide, and continuously add 1210g ethylene oxide to react to obtain crude polyether, which is neutralized and refined to obtain soft foam flame-retardant polyet...

Embodiment 3

[0031] Add 126g of melamine and 244g of formaldehyde solution with a mass fraction of 37% into a 5L stainless steel reaction kettle, pump in 5g of triethylamine, and react at 70°C for 3h to obtain 216g of melamine-formaldehyde condensate; then add 92g of glycerol and continue the reaction for 1h , Dehydration under reduced pressure at 70°C to a moisture content of 5%. Raise the temperature to 80°C, start to add propylene oxide, keep the pressure in the kettle at 0.1-0.4MPa, and the temperature is 80-100°C, continuously add 522g of propylene oxide. After the feeding of propylene oxide is completed, the internal pressure will be reacted for 3 hours, and the pressure will be removed. The unreacted propylene oxide and water can obtain high hydroxyl value polyether with moisture content ≤ 0.01%, and its hydroxyl value is 558mgKOH / g.

[0032] Add 4.2 g CH to the reactor 3 ONa, heat up to 110°C, start to add propylene oxide, continuously add 1680g propylene oxide, react to get crude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com