Method for dissolving cellulose and method for preparing regenerated fiber

A technology for dissolving cellulose and solvent, applied in the direction of rayon filament in cellulose solution, can solve the problems of lower quality of cellulose products, difficult industrialization, short time, etc., to improve cellulose concentration, avoid cellulose degradation, Environmentally friendly manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

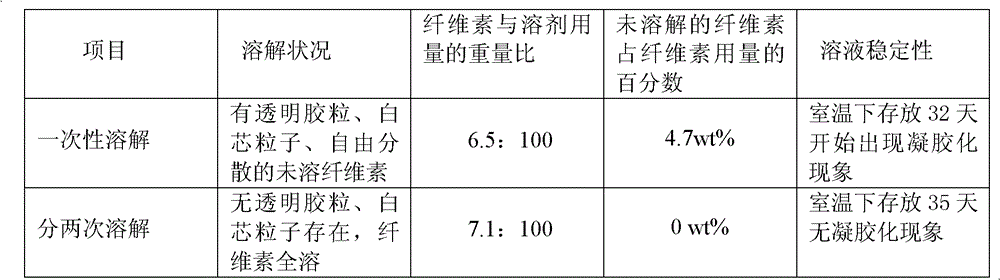

Embodiment 1

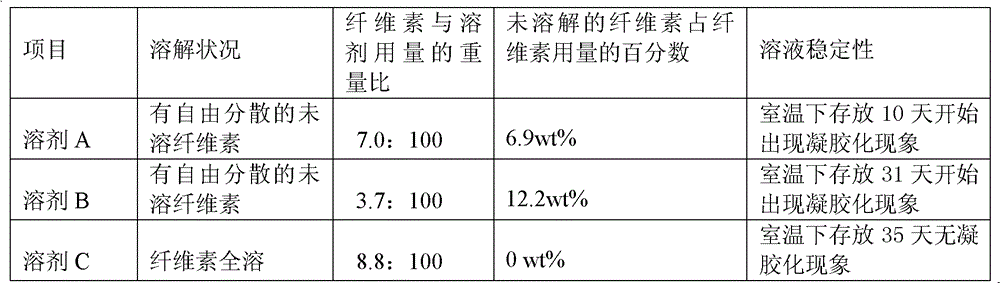

[0051] 3.6g of dried wood pulp (polymerization degree 400) and 40g of 7.5wt% sodium hydroxide / 11.0wt% urea / 1.5wt% polyethylene glycol (molecular weight 800) mixed aqueous solution were kneaded and sheared and mixed evenly at 8°C, Then add 60g of 7.5wt% sodium hydroxide / 11.0wt% urea / 1.5wt% polyethylene glycol (molecular weight 800) mixed aqueous solution of -15°C to it, and place it at 25°C for kneading and shearing to mix evenly, and the fiber The element can be completely dissolved to obtain a uniform and transparent cellulose solution. The cellulose solution was stored at room temperature for 35 days without significant gelation.

Embodiment 2

[0053] 3.8g dried bamboo pulp (polymerization degree 400) and 30g 9.2wt% sodium hydroxide / 4.5wt% thiourea / 0.4wt% polyethylene glycol (molecular weight 4000) mixed aqueous solution are kneaded and sheared at 25 ℃ and mixed evenly , and then adding 70g of 9.2wt% sodium hydroxide / 4.5wt% thiourea / 0.4wt% polyethylene glycol (molecular weight 4000) mixed aqueous solution to which the temperature is -8°C, and kneading and shear mixing at -2°C Evenly, the cellulose can be completely dissolved to obtain a uniform and transparent cellulose solution. The cellulose solution was stored at room temperature for 35 days without significant gelation.

Embodiment 3

[0055] 5.0g of dried cotton pulp (polymerization degree 500) and 70g of 5.0wt% lithium hydroxide / 12.0wt% urea / 5.5wt% polyethylene glycol (molecular weight 150) mixed aqueous solution were kneaded and sheared at 0°C and mixed uniformly, Then add 30g of a mixed aqueous solution of 5.0wt% lithium hydroxide / 12.0wt% urea / 5.5wt% polyethylene glycol (molecular weight 150) at a temperature of -15°C, and place it at -8°C for kneading and shearing to mix evenly. The cellulose can be completely dissolved to obtain a uniform and transparent cellulose solution. The cellulose solution was stored at room temperature for 35 days without significant gelation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com