Micro-emulsified environment-friendly diesel fuel additive

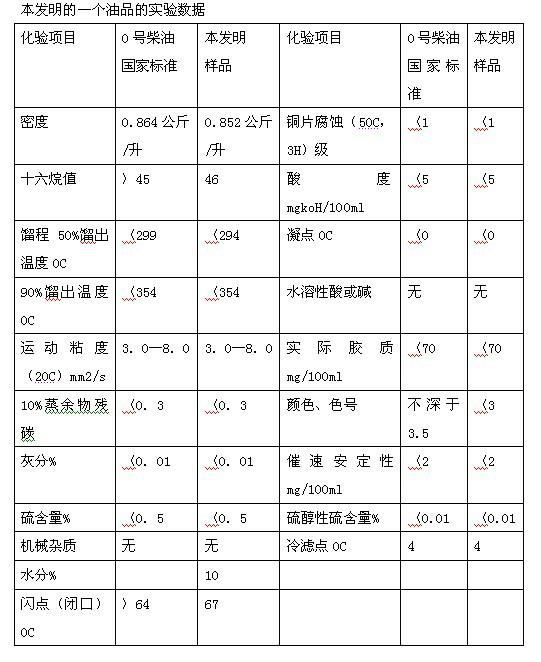

A micro-emulsification and additive technology, which is used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., and can solve the problems that technical indicators cannot reach diesel data, pollute the air, and consume large gasoline and diesel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 58 kg of high acid value grease, 18 kg of alkali catalyst, 5 kg of emulsifier, 6 kg of cosolvent, 5 kg of cetane number improver, 2 kg of smoke suppressant, 1 kg of cleaning agent, 3 kg of auxiliary agent, pour point depressant 2 kg dose, total 100 kg. Among them, the high-acid value oil is a mixture of fatty acids, tricyclic acids, and abietic acids, generally one-third each, and the alkali catalyst is a mixture of triethanolamine, diethylamine, polyethylene polyamine, sodium hydroxide, and amine hydroxide. Take equal amounts of each, the emulsifier is a mixture of alkylphenol polyoxyethylene ether, polyoxyethylene sorbitan fatty acid ester, and sorbitan fatty acid ester, each can take equal amounts, and the cosolvent is isopropanol The mixture of isoamyl alcohol and n-butanol can be taken in equal amounts. The cetane number improver is a mixture of amyl nitrate and cyclohexyl nitrate. The mixture of pentadiene trihydroxymanganese and dicyclopentadienyl iron can ...

Embodiment 2

[0019] Take 70 kg of high acid value oil, 12 kg of alkali catalyst, 3 kg of emulsifier, 5 kg of cosolvent, 4 kg of cetane number improver, 1 kg of smoke suppressant, 1 kg of cleaning agent, 2 kg of auxiliary agent, pour point depressant 2 kg dose, total 100 kg. Among them, the high acid value oil is a mixture of fatty acid and tricyclic acid, generally half of each, the alkali catalyst is a mixture of triethanolamine, diethylamine, polyethylene polyamine, each can be taken in equal amounts, and the emulsifier is alkylphenol polyoxyethylene The mixture of ether and polyoxyethylene sorbitan fatty acid ester can be taken in equal amounts, the cosolvent is a mixture of isopropanol and isoamyl alcohol, which can be taken in equal amounts, and the cetane number improver is made of nitric acid Amyl fat, the smoke suppressant is made of methylcyclopentadiene trihydroxy manganese, the cleaning agent is made of diamide soybean amide, the auxiliary agent is a mixture of cobalt naphthenat...

Embodiment 3

[0021] Take 65 kg of high acid value grease, 13 kg of alkali catalyst, 5 kg of emulsifier, 6 kg of cosolvent, 5 kg of cetane number improver, 2 kg of smoke suppressant, 1 kg of cleaning agent, 1 kg of auxiliary agent, pour point depressant 2 kg dose, total 100 kg. Among them, the high acid value oil is fatty acid, the alkali catalyst is triethanolamine, the emulsifier is alkylphenol polyoxyethylene ether, the cosolvent is a mixture of isoamyl alcohol, the cetane number improver is amyl nitrate, and the smoke suppressant is It is made of methylcyclopentadiene trihydroxy manganese, the cleaning agent is made of diamide soybean amide, the auxiliary agent is fatty acid copper, and the pour point depressant is made of ethylene-acrylate copolymer. Put the above ingredients into the blender, stir for 30 minutes, and then bottle it for later use. It should be stored in a cool place away from the sun at ordinary times, and the storage temperature is between 5 and 20 degrees. When in u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com