Dual-functional hollow nanocomposite oxide material and preparation and application thereof

A technology of composite oxides and hollow nanometers, which is applied in the direction of hydrocarbon oxidation to prepare oxygenated compounds, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., and can solve the problems of easy coking, low selectivity, and conversion Low efficiency and other problems, to achieve high activity and selectivity, improve over-reaction, and improve selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 Material A (Co-SiO 2 -Me) Preparation

[0021] Mix 8.00g Np-12, 15.00g cyclohexane and 3.00g n-octanol to obtain solution A; dissolve 0.02g cobalt acetate in 3.00g deionized water, and add 1.00g ammonia water to obtain solution B; 1.00g orthosilicate Methyl ester and 0.10g methyltrimethoxysilane are solution C; pour solution B into solution A to obtain solution D, add solution C to solution D under stirring, and age for 8 hours; then, add 7g of acetone, stir for 30min, Centrifuge to obtain a solid;

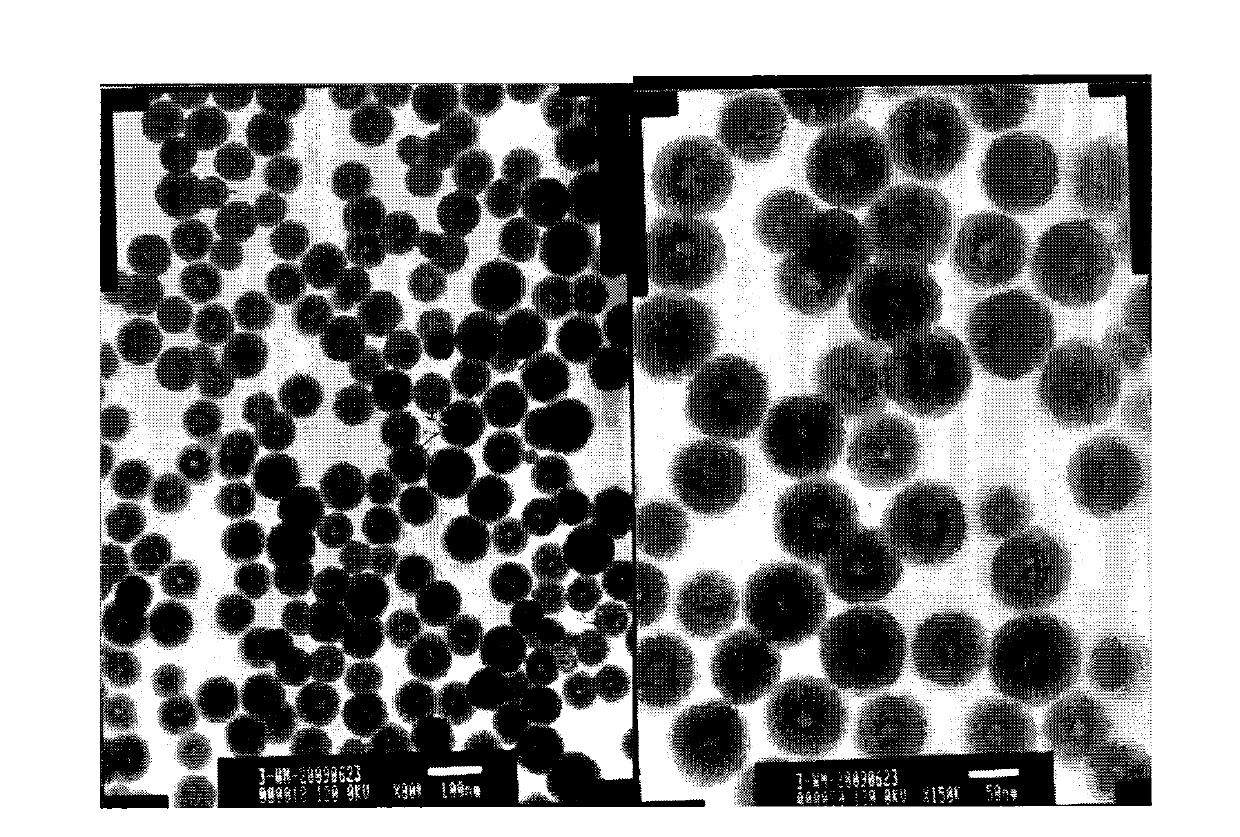

[0022] Add 20g of ethanol to the solid, heat and stir for 10min, and centrifuge; repeat this step 3-6 times until the surfactant is removed; dry at 80°C to obtain the final nanomaterial Co-SiO 2 -Me. Such as figure 1 As shown, it can be seen that the prepared material has a uniform particle size, good dispersion, a particle size of about 60nm, and a cavity diameter of 10nm.

Embodiment 2

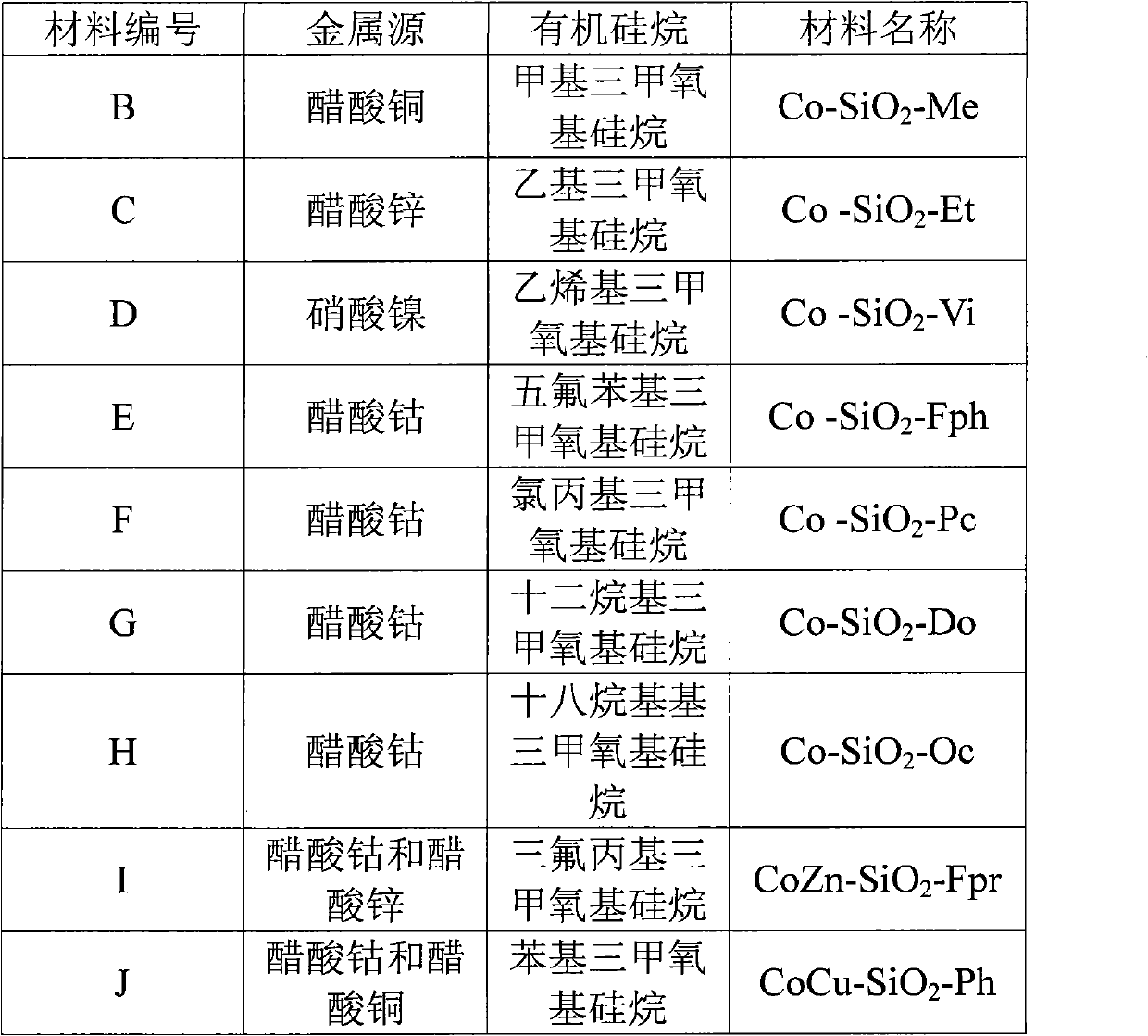

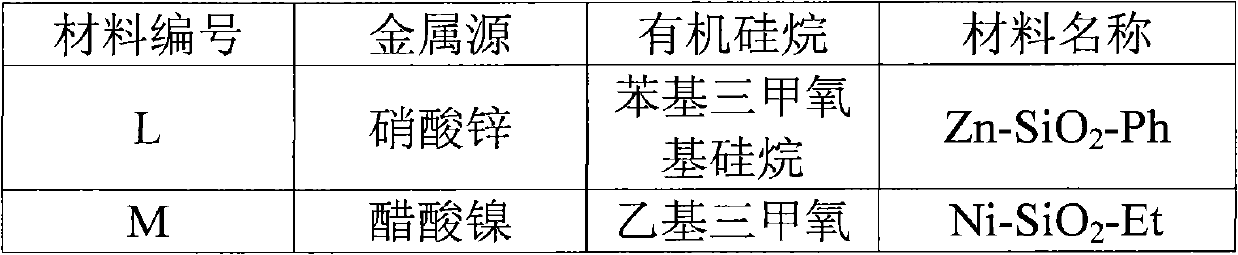

[0023] The preparation of embodiment 2 material B-L

[0024] The preparation method of materials B-L is the same as that of material A, the difference lies in the types of metal sources or organosilanes, the specific types of metal sources and organosilanes used are shown in Table 1, and the obtained materials are listed in Table 1.

[0025] The type of metal source and organosilane used in the preparation of material B-L in table 1

[0026]

Embodiment 3

[0027] Embodiment 3 material K (Cu-SiO 2 -Ph) Preparation

[0028] Mix 2.00g sodium dodecylbenzenesulfonate, 10.00g n-hexane and 1.00g n-butanol to obtain solution A; dissolve 0.02g cupric chloride in 2.00g deionized water, and add 2.00g ammonia water to obtain solution B; 1.00g methyl orthosilicate and 0.30 phenyltrimethoxysilane as solution C; pour solution B into solution A to obtain microemulsion D, add solution C to solution D under stirring, and age for 18 hours; then, add 7g Acetone, stirred for 30min, and centrifuged to obtain a solid;

[0029] Add 20g of ethanol to the solid, heat and stir for 10min, and centrifuge; repeat this step 4 times until the surfactant is removed; dry at 80°C to obtain the final nanomaterial Cu-SiO2 -Ph.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com