Method for synthesizing IM-5 molecular sieve

A technology of IM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of narrow synthesis range, difficult amplification, and narrow proportioning range, so as to shorten the crystallization time, shorten the synthesis time, and improve the single-pot Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

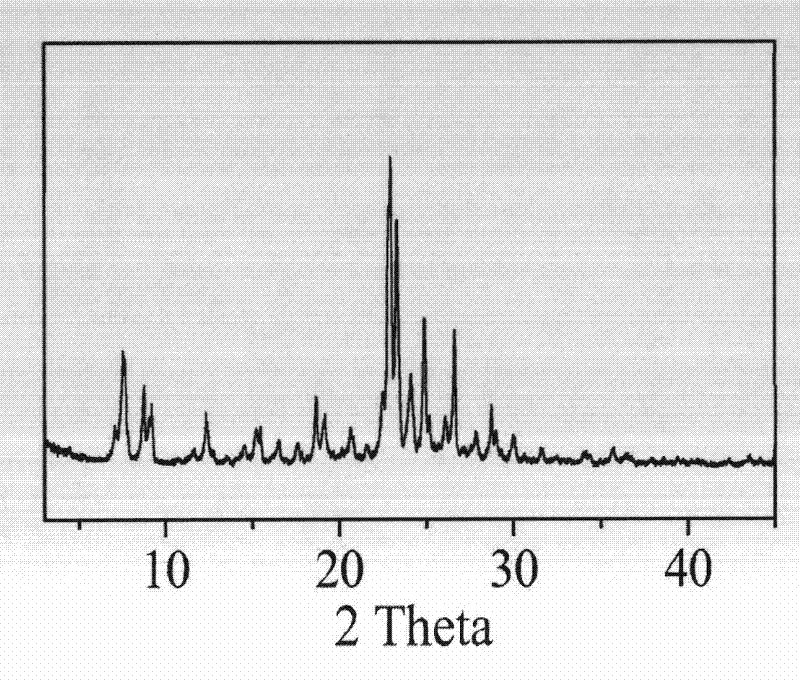

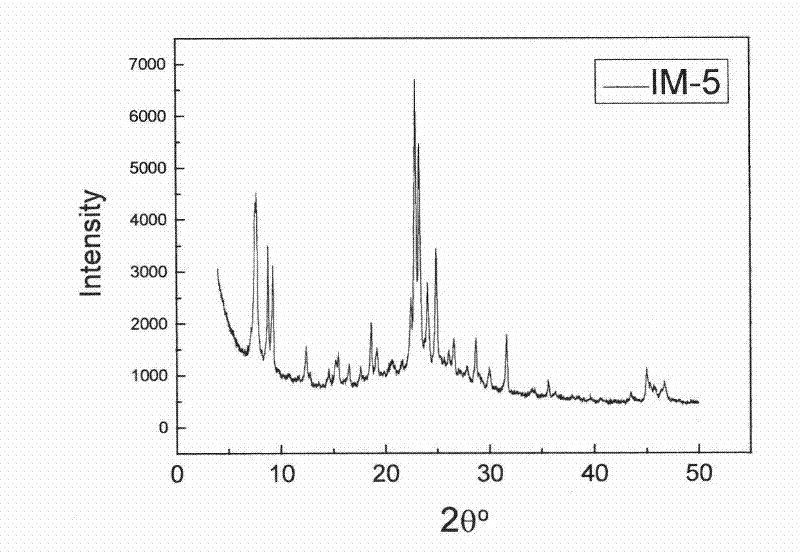

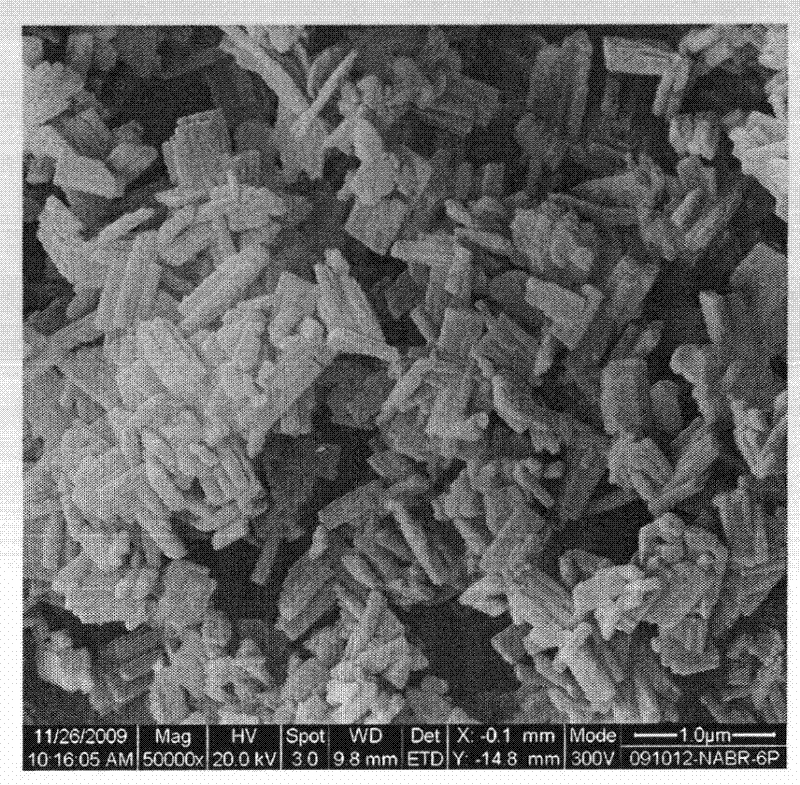

[0056] Example 1 illustrates the synthesis method of the IM-5 molecular sieve provided by the present invention.

[0057] (1) Sodium metaaluminate (NaAlO 2 ) solution preparation

[0058] Weigh 194g NaOH and dissolve in about 500ml deionized water, add 153g pseudo-boehmite (solid content 66.3%), and cook for 30min to obtain a clear and transparent solution. The obtained liquid was dubbed into 1L solution while it was hot, and cooled for later use.

[0059] (2) Dissolve 2.95g NaOH in 25.57g deionized water, then add 4.01g NaAlO prepared in step (1) 2 The aqueous solution and 27.40 g of 1,5-bis(N-methylpyrrolidine) pentane bromide salt solution were uniformly mixed, and under stirring, 40 g of alkaline silica sol was slowly added dropwise to form a colloid, and the stirring was continued for 2 hours. The molar composition of the reaction mixture is: SiO 2 :Al 2 o 3 :Na 2 O:R:H 2 O=60:1:13.5:9:1200, the ratio of water to silicon is 20:1. Transfer the prepared colloid to ...

Embodiment 2

[0061] Example 2 illustrates the synthesis method of the IM-5 molecular sieve provided by the present invention.

[0062] 1.65g NaOH is dissolved in 24.66g deionized water, then add the NaAlO prepared in 12.04g embodiment 1 step (1) 2 The aqueous solution and 18.27g of 1,5-bis(N-methylpyrrolidine)pentane bromide salt solution were mixed evenly, and under the condition of stirring, 40g of alkaline silica sol was slowly added dropwise, and then SiO 2 The calcined IM-5 molecular sieve with a weight of 5wt% was used as a seed crystal (seed) to make a colloid, and the stirring was continued for 2 hours. The molar composition of the reaction mixture is: SiO 2 :Al 2 o 3 :Na 2 O:R:H2O=60:3:13.5:6:1200, the ratio of water to silicon is 20:1. Transfer the prepared colloid to a 50ml polytetrafluoroethylene-lined autoclave, rotate and crystallize at 160°C for 5 days, stop the crystallization reaction, wash and filter the product, and dry it overnight at 80°C to obtain IM -5 molecula...

Embodiment 3

[0064] Example 3 illustrates the synthesis method of the IM-5 molecular sieve provided by the present invention.

[0065] Dissolve 2.88g NaOH and 2.06g NaBr in 21.95g deionized water, then add the 2.01g NaAlO prepared in Example 1 step (1) 2 The aqueous solution and 36.54g of 1,5-bis(N-methylpyrrolidine)pentane bromide salt solution were mixed evenly, and 40g of alkaline silica sol was slowly added dropwise under stirring to form a colloid, and the stirring was continued for 2 hours. The molar composition of the reaction mixture is: SiO 2 :Al 2 o 3 :Na 2 O:NaBr:R:H 2 O=60:0.5:12:6:12:1200, the ratio of water to silicon is 20:1. Transfer the obtained colloid to a 50ml polytetrafluoroethylene-lined autoclave, rotate and crystallize at 160°C for 4 days, stop the crystallization reaction, wash and filter the product, and dry it overnight at 80°C to obtain IM -5 molecular sieves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com