Polyaniline/carbon nano tube adsorbent having multi-layer porous structure and preparation method thereof

A carbon nanotube and polyaniline technology, applied in the fields of nanocomposite materials and environmental protection, can solve the problems of large aspect ratio of carbon nanotubes, inability to uniformly disperse and agglomerate, easy to curl and entangle, and improve adsorption efficiency and adsorption capacity. , The effect of good adsorption performance and high adsorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

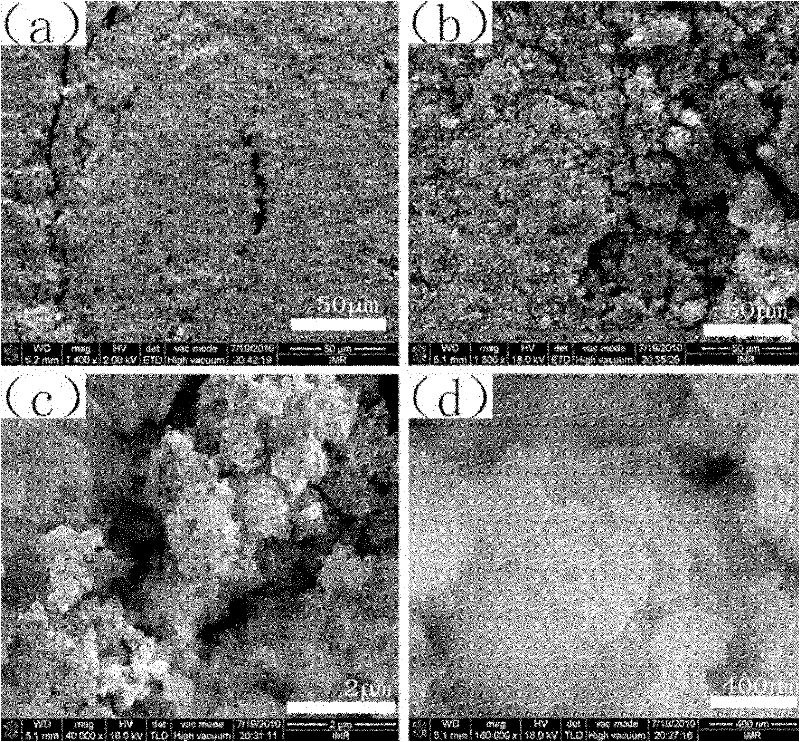

[0027] First, 0.34g of carbon nanotubes (in this embodiment, the carbon nanotubes have a diameter of 5-200 nanometers, a length of 0.1-100 microns, and a specific surface area of 30-300m 2 / g, carbon nanotubes that are prone to curling and entanglement) and 6.8g oxidant ammonium persulfate were dissolved in 100ml distilled water. Ultrasonic dispersion was placed in an ultrasonic generator for 2 h, and then cooled to room temperature. At the same time, 2.27ml of aniline monomer (analytically pure, with a purity greater than 99.8wt%) was dissolved in 100ml of organic solvent n-hexane. Then the n-hexane solution of aniline is firstly transferred into the reaction flask, and the ammonium persulfate solution containing carbon nanotubes is transferred into the reaction cup. At this time, the organic phase and the aqueous phase form an interface. Emerald green polyaniline is formed at the interface in an instant, and gradually diffuses into the water phase, wrapping on the surfac...

Embodiment 2

[0032] First, 0.23g of carbon nanotubes (in this embodiment, the carbon nanotubes have a diameter of 5-200 nanometers, a length of 0.1-100 microns, and a specific surface area of 30-300m 2 / g, carbon nanotubes that are prone to curling and entanglement) and 5.7g oxidant ammonium persulfate were dissolved in 50ml distilled water. Ultrasonic dispersion was placed in an ultrasonic generator for 2 h, and then cooled to room temperature. At the same time, 2.27ml of aniline monomer (analytically pure, with a purity greater than 99.8wt%) was dissolved in 50ml of organic solvent carbon tetrachloride. Then the carbon tetrachloride solution of aniline was first moved into the reaction bottle, and the ammonium persulfate solution containing carbon nanotubes was moved into the reaction cup. At this time, the organic phase and the aqueous phase form an interface. Emerald green polyaniline is formed at the interface in an instant, and gradually diffuses into the water phase, wrapping on ...

Embodiment 3

[0036] First, 0.12g of carbon nanotubes (in this embodiment, the carbon nanotubes have a diameter of 5-200 nanometers, a length of 0.1-100 microns, and a specific surface area of 30-300m 2 / g, carbon nanotubes that are prone to curling and entanglement) and 4.5g oxidant ammonium persulfate were dissolved in 30ml distilled water. Ultrasonic dispersion was placed in an ultrasonic generator for 2 h, and then cooled to room temperature. At the same time, 2.27ml of aniline monomer (analytically pure, with a purity greater than 99.8wt%) was dissolved in 30ml of organic solvent xylene. Then the xylene solution of aniline is firstly transferred into the reaction flask, and the ammonium persulfate solution containing carbon nanotubes is transferred into the reaction cup. At this time, the organic phase and the aqueous phase form an interface. Emerald green polyaniline is formed at the interface in an instant, and gradually diffuses into the water phase, wrapping on the surface of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com