Low-smoke halogen-free flame-retardant antistatic aging-resistant wire and cable material and its preparation method

A wire and cable material, flame retardant and antistatic technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor antistatic performance, easy aging, casualties, etc., and achieve good elongation, good flame retardancy and fire resistance , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

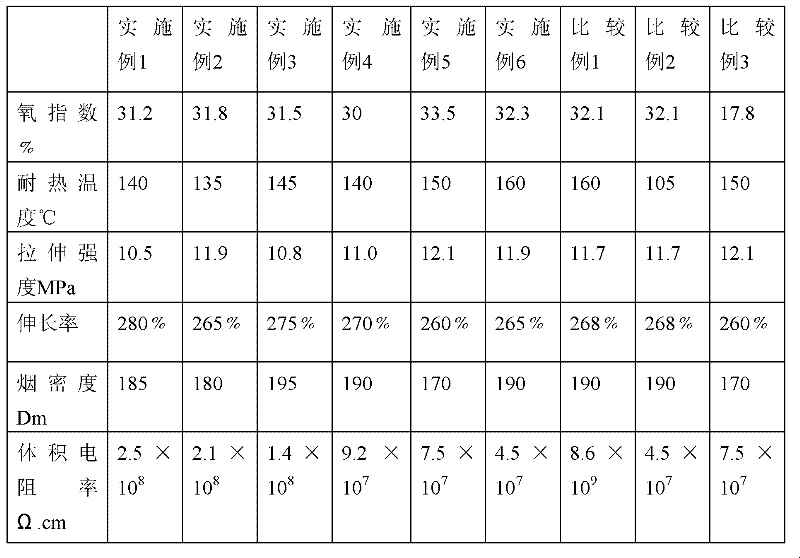

Examples

Embodiment 1

[0034] First, the base material consisting of 60 parts of linear low density polyethylene and 15 parts of ethylene / vinyl acetate copolymer was thoroughly mixed in a mixer for 3 minutes, and 20 parts of epoxy resin coated ammonium polyphosphate, 12 parts of pentaerythritol, melamine urea 10 parts of acid salts, 60 parts of aluminum hydroxide and 25 parts of zinc borate composite inorganic flame retardant, 3 parts of lubricating oil, 8 parts of maleic anhydride grafted EVA were added in the mixer and stirred for 5 minutes. Distribute the remaining components (1.5 parts of triallyl tripolyisocyanate, 0.3 parts of ethylene glycol lauric acid amide, 10100.5 parts of antioxidant, 0.1 part of auxiliary antioxidant DLTP, 0.2 part of oxalic acid dihydrazide) and then stir Mix for 5 minutes. Knead at 200°C for 1.5 hours, and pulverize, and the speed of the kneader is 840 r / min. The above-mentioned fully mixed mixed components are extruded through an extruder to obtain pellets, which ar...

Embodiment 2

[0036]First, the base material composed of 75 parts of linear low density polyethylene and 20 parts of ethylene / vinyl acetate copolymer was thoroughly mixed in a mixer for 3 minutes, and 25 parts of ammonium polyphosphate, 15 parts of pentaerythritol and melamine urea were coated with epoxy resin. 12 parts of acid salts, 55 parts of aluminum hydroxide and 20 parts of zinc borate composite inorganic flame retardant, 2 parts of lubricating oil, 7.5 parts of maleic anhydride grafted EVA were added in the mixer and stirred for 5 minutes, and the mixed group was mixed. The remaining components (0.5 part of triallyl isocyanate, 0.3 part of ethylene glycol lauric acid amide, 10100.4 parts of antioxidant, 0.2 part of oxalic acid dihydrazide) were distributed and mixed for 8 minutes. Knead at 195° C. for 1.5 hours, and pulverize, and the kneader rotates at 700 r / min. The above-mentioned fully mixed mixed components are extruded through an extruder to obtain pellets, which are then coat...

Embodiment 3

[0038] First, the base material consisting of 70 parts of linear low-density polyethylene and 15 parts of ethylene / vinyl acetate copolymer was thoroughly mixed in a mixer for 3 minutes, and 25 parts of ammonium polyphosphate, 10 parts of pentaerythritol, melamine urea were coated with epoxy resin 8 parts of acid salts, 52 parts of aluminum hydroxide and 21 parts of zinc borate composite inorganic flame retardant, 1.5 parts of lubricating oil, 7.8 parts of maleic anhydride grafted EVA were added in the mixer and stirred for 5 minutes. Divide the remaining components (1 part of triallyl isocyanate, 0.5 part of ethylene glycol lauric acid amide, 0.3 part of antioxidant 1010, 0.2 part of auxiliary antioxidant DLTP, 0.2 part of oxalic acid dihydrazide) Stir to mix for 5 minutes. Knead at 190°C for 1.5 hours, and pulverize, and the kneader rotates at 900 r / min. The above-mentioned fully mixed mixed components are extruded through an extruder to obtain pellets, which are then coated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com