Electroluminescent material and preparation method thereof

An electroluminescent and chemical technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of poor stability of sulfide system, uneven emission of electrons, and decrease in the number of emitted electrons, achieving good stability and high product quality , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

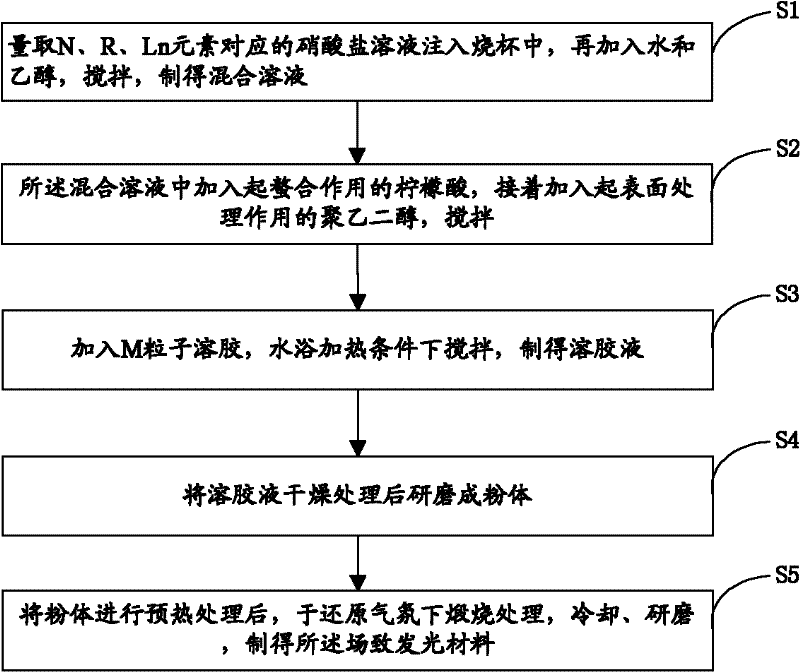

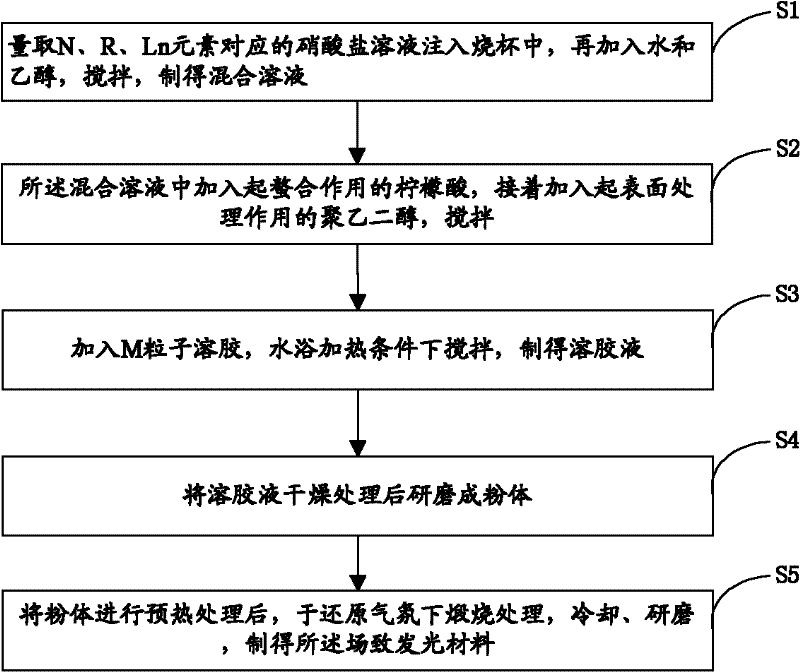

[0022] The preparation method of above-mentioned electroluminescent material, such as figure 1 As shown, the preparation process is as follows:

[0023] Step S1, at room temperature, according to the general chemical formula N 1-x R 2 o 4 : xLn, the stoichiometric ratio of each element in zM, measure the nitrate solution corresponding to N, R, Ln elements and inject in the beaker, add water and ethanol again, stir, make mixed solution; Wherein, N is Zn, Ca, One or both of Sr or Ba; R is one or both of Al and Ga; Ln is Tm 3+ , Tb 3+ 、Eu 3+ 、Sm 3+ 、Ce 3+ or Dy 3+ One or two of them; M is one or two of Ag, Au, Pt or Pd nanoparticles; 0.0001≤x≤0.2, 0-2 ;

[0024] Step S2, adding citric acid for chelation to the mixed solution in step S1, then adding polyethylene glycol for surface treatment, and stirring;

[0025] Step S3, according to the general chemical formula N 1-x R 2 o 4 : xLn, the stoichiometric ratio of each element in zM, add the surface-treated M nanopartic...

Embodiment 1

[0037] Embodiment 1: Sol-gel method prepares Zn 0.999 Al 2 o 4 :0.001Dy, 1×10 -3 Pt

[0038] Weigh 5.18mg chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) be dissolved in the deionized water of 17mL; After chloroplatinic acid dissolves completely, take by weighing 8.0mg sodium citrate and 12.0mg sodium dodecylsulfonate, and dissolve in the chloroplatinic acid aqueous solution under the environment of magnetic stirring ; Weigh 0.38mg sodium borohydride and dissolve it in 10mL deionized water to obtain 10mL concentration of 1×10 -3 mol / L sodium borohydride aqueous solution, while preparing 10mL concentration of 1×10 -2 mol / L hydrazine hydrate solution; in the environment of magnetic stirring, first drop 0.4mL sodium borohydride aqueous solution into the chloroplatinic acid aqueous solution, stir for 5min, and then add dropwise 2.6mL1×10 -2 mol / L hydrazine hydrate solution, and then continue to react for 40min to obtain 20mL Pt content of 5×10 -4 mol / L Pt nanoparticle sol; then ...

Embodiment 2

[0040] Embodiment 2: Sol-gel method prepares Ca 0.995 Ga 2 o 4 :0.005Sm, 2×10 -3 Au

[0041] Weigh 16.48mg of chloroauric acid (AuCl 3 ·HCl·4H 2 O) be dissolved in the deionized water of 8.4mL; After chloroauric acid is completely dissolved, take by weighing 14mg sodium citrate and 6mg cetyltrimethylammonium bromide, and dissolve into chloroauric acid under the environment of magnetic stirring aqueous solution; weigh 1.9mg of sodium borohydride and 17.6mg of ascorbic acid were dissolved in 10mL of deionized water to obtain 10mL concentration of 5 × 10 -3 mol / L sodium borohydride aqueous solution and 10mL concentration is 1×10 -2 mol / L ascorbic acid aqueous solution; in the environment of magnetic stirring, first add 0.04mL sodium borohydride aqueous solution to the chloroauric acid aqueous solution, stir and react for 5 minutes, then add 1.56mL1×10 -2 mol / L ascorbic acid aqueous solution, and then continue to react for 30min to obtain 10mL Au content of 4×10 -3 mol / L A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com