Coating composition and its application in lampshade coatings

A composition and coating technology, applied in the coating composition and its application field in lampshade coatings, can solve the problems of increasing VOC emissions, reducing luminous efficiency, reducing light transmittance, etc., to save raw materials, light transmittance and fog High degree, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] According to the present invention, the coating composition of the present invention can be obtained by various existing methods, and the present invention has no special requirements. According to a preferred embodiment of the present invention, the method, for example, may include the following steps:

[0038] (1) Weigh the aforementioned solvents as required (such as esters, aromatic hydrocarbons and ketones, specifically butyl acetate, isopropanol, n-butanol, cyclohexanone, xylene, ethylene glycol butyl ether, methyl one or more of the base isobutyl ketone).

[0039] (2) Weigh the required resins (thermoplastic acrylic resins) according to the requirements, and add them to the above-mentioned solvents respectively (the order of addition is arbitrary), and continue to stir for 10-100 minutes before proceeding to the next step.

[0040] (3), according to the requirements, weigh the various fillers required, and add them to the above solution (the order of addition is ...

Embodiment 1

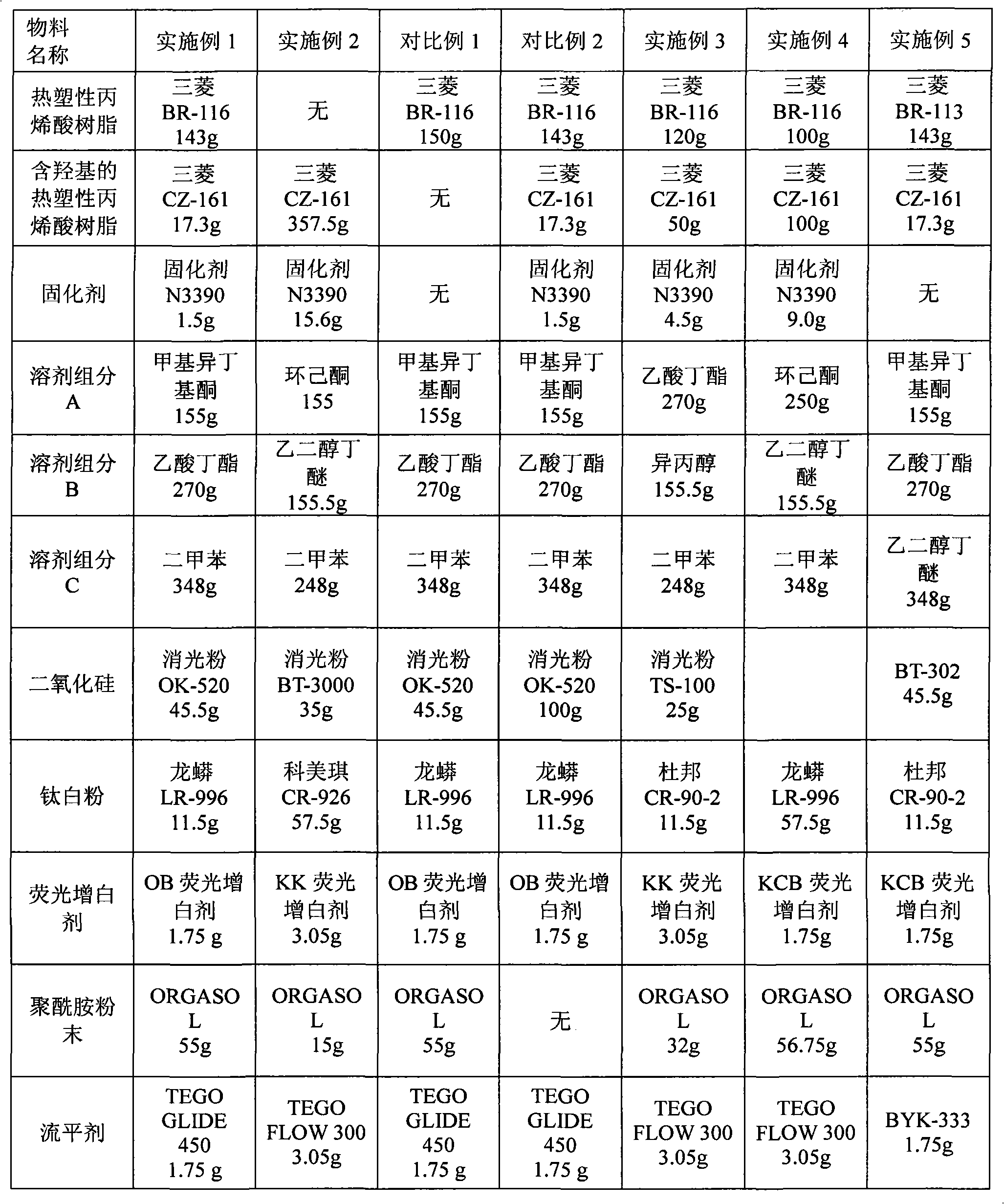

[0054] Use raw material as shown in table 1, prepare lampshade coating according to the following method:

[0055] (1) Weigh the above-mentioned mixed solvent as required (see Table 1 for the type and dosage), stir (500r / min) under the high-speed disperser, and proceed to the next step after 10 minutes.

[0056] (2) Weigh the required resins according to the requirements (see Table 1 for product grades and dosages), and add them to the above-mentioned mixed solvents (in any order), and continue to stir for 13 minutes before proceeding to the next step.

[0057] (3) Weigh the required matting powder, polyamide wax micropowder (PA wax powder), titanium dioxide and fluorescent whitening agent (see Table 1 for product grade and dosage) according to the requirements, and add them to the solution of step (2) In (arbitrary order of adding), continue to stir for 5 minutes and proceed to the next step.

[0058](4) Take the required additives according to the requirements (see Table 1 ...

Embodiment 2-5

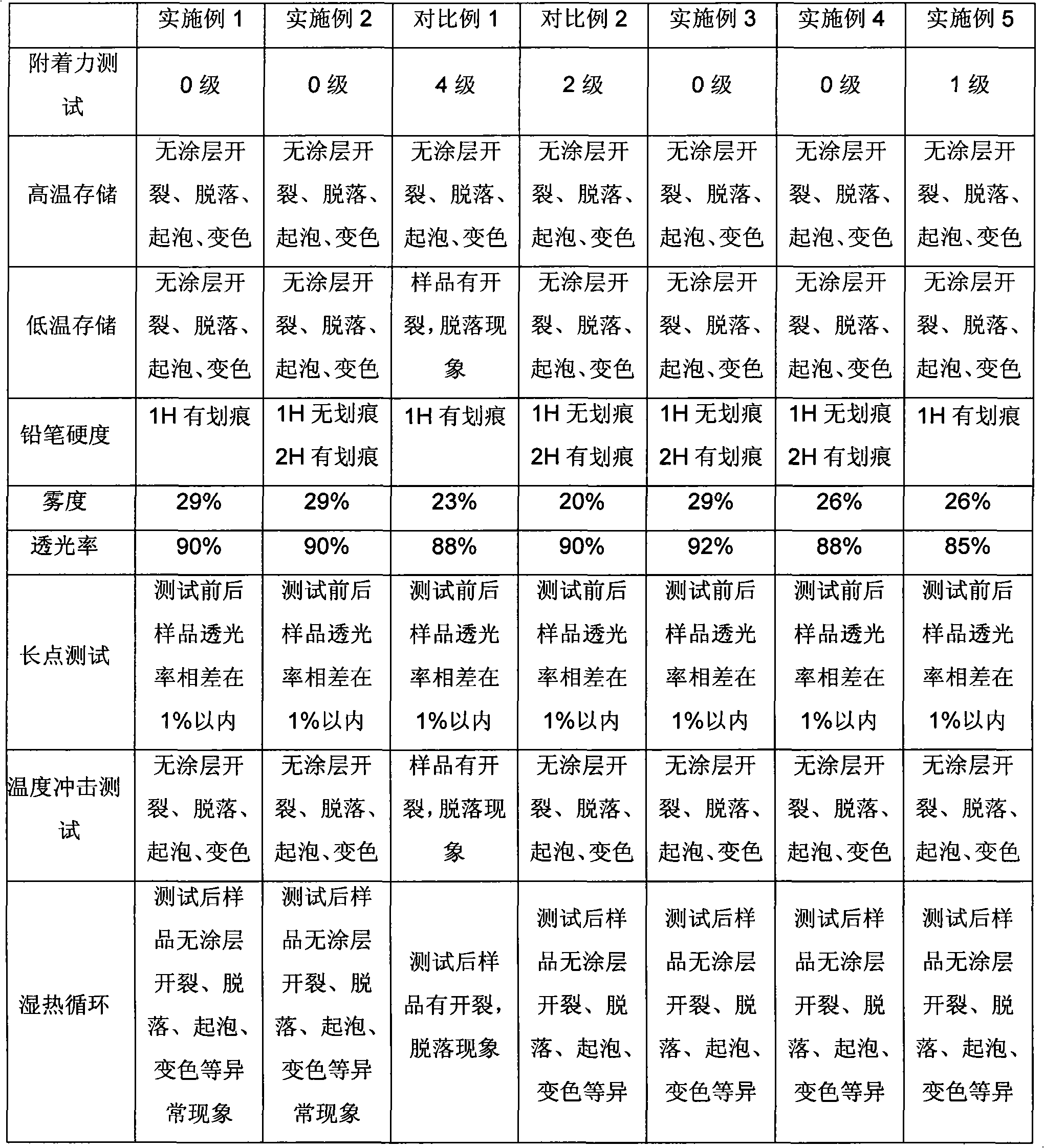

[0065] The preparation method is the same as that of Example 1, except that the types and amounts of substances are different, see Table 1 for details. The obtained coating composition was sprayed, and the spraying method was consistent with that of Example 1, and various performance tests were carried out, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com