Preparation method of composite ordered porous nanometer titanium dioxide (TiO2) film

A nano-titanium dioxide and thin film technology, applied in the field of dye-sensitized solar cells, can solve problems such as electron-hole recombination, achieve the effects of large specific surface area, inhibit electron-hole recombination, and increase adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

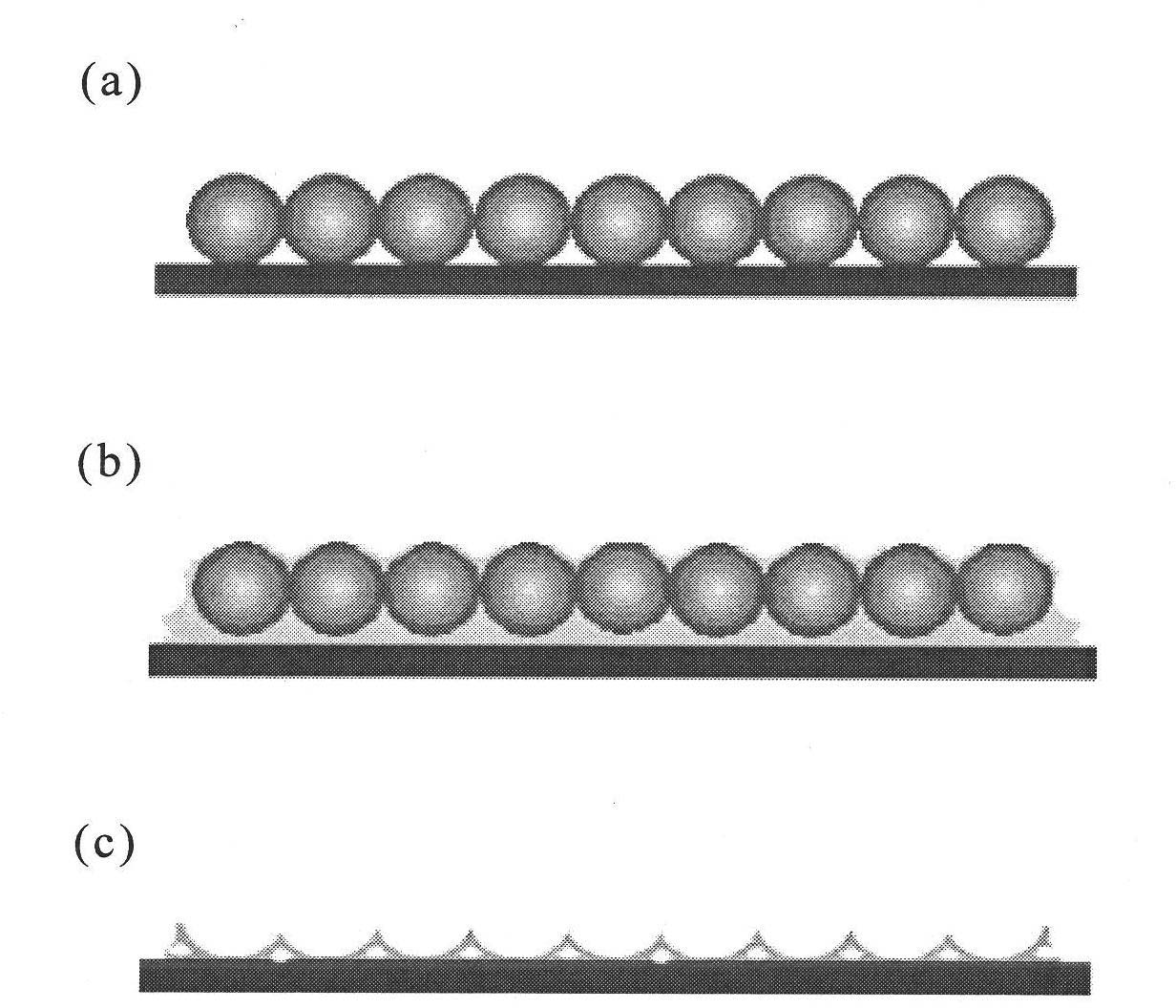

[0024] Below in conjunction with example and accompanying drawing, the present invention is described in further detail.

[0025] Preparation of polystyrene microsphere emulsion and assembly of polystyrene microsphere colloidal crystal template: Pour styrene into a separatory funnel, wash it four times with 0.1M NaOH solution and secondary deionized water to remove inhibition Add 40mL of secondary deionized water and 0.0125g of sodium dodecylbenzenesulfonate into a 100mL four-necked flask, stir to dissolve, heat the water bath to 78°C, and then pass in nitrogen, then add 0.04g of NaHCO 3 and 10mL of washed styrene monomer; continue to heat and reflux and stir for 1 hour, and 0.1gK 2 S 2 o 8 Dissolve it in 10mL of secondary deionized water and drop it into a flask, control the temperature at (78±2)°C, heat to reflux and stir to react for 12 hours, then stop the reaction to obtain a polystyrene microsphere emulsion with a particle size of 450nm.

[0026] Using FTO conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com