Preparation method for superfine bupleurum powder under normal temperature and special bidirectional airflow sieving machine

A technology of ultrafine powder and airflow sieve, which is applied in the direction of separating solids from solids with airflow, chemical instruments and methods, and solid separation, etc., which can solve the constraints of large-scale production of ultrafine powders of traditional Chinese medicine for veterinary use, reduced crushing efficiency, and biological utilization. It is suitable for large-scale industrial production, improves the smell and taste, and increases the cell wall breaking rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

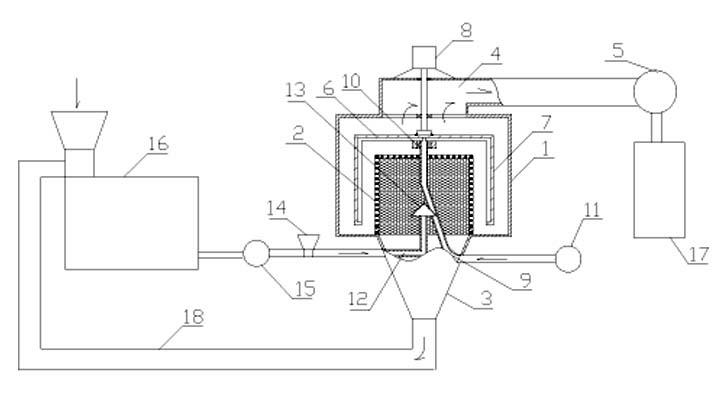

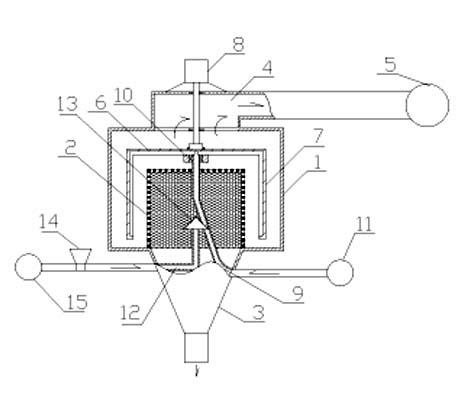

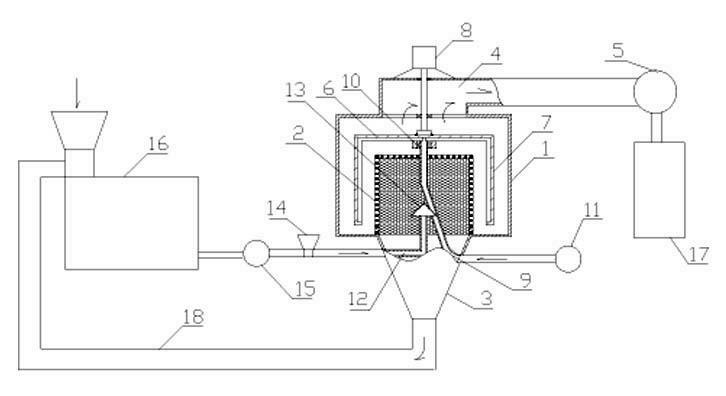

[0034] Such as figure 1 , 2 Shown, the normal temperature preparation method of superfine powder Xiaochaihu powder of the present invention, comprises the following steps:

[0035] Step 1: Select Bupleurum, Scutellaria, Ginger Pinellia, Codonopsis pilosula, and Licorice, select them, cut them into 3-5cm long sections, and dry them naturally or until the moisture content is ≤10%;

[0036] In the second step, the above raw materials are respectively pulverized at a temperature of 20° C. to 25° C. to obtain coarse powder of traditional Chinese medicine with a particle size of 60 to 80 meshes;

[0037] The 3rd step, above-mentioned crude drug coarse powder is mixed according to the weight ratio of Radix Bupleurum: Radix Scutellariae: Ginger Pinellia: Codonopsis: Radix Glycyrrhizae=3:3:2:3:1;

[0038] In the fourth step, first turn on the powder conveying fan 15, the induced draft fan 5, the blower 11, and the drive motor 8. The blowing pressure of the powder conveying fan 15 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com