Hydrophilic strong anion exchange action hybrid silica gel capillary chromatographic column

A technology of capillary electrochromatography and strong anions, applied in the field of capillary electrochromatography, can solve problems such as poor compatibility and incompatibility, achieve uniform distribution, increase polarity, and apply to a wide range of separation objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

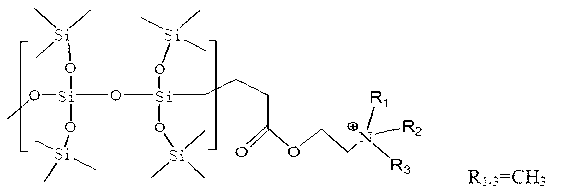

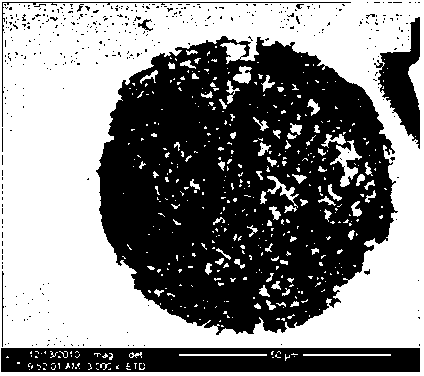

[0019] Mix tetramethoxysilane and vinyltrimethoxysilane in a volume ratio of 3:1 to 5:1, 0.27g polyethylene glycol and 2.5mL of 0.01mol / L acetic acid solution in an ice-water bath Stir and hydrolyze to obtain a sol, take 0.5 mL of the sol solution and one of 30-40 mg of acryloyloxyethyltrimethylammonium chloride, 0.7-1.0 mg of azobisisobutyramidine hydrochloride or ammonium persulfate, and ultrasonically After shaking and mixing, the mixture was injected into the pretreated quartz capillary. Both ends of the capillary were closed, immersed in a 40°C water bath for 12 hours, and then transferred to a 60°C water bath for 12 hours. After the reaction was completed, the capillary column was rinsed with deionized water and methanol mobile phase to remove the residual reagents in the column to obtain a polar Ion exchange hybrid silica gel electrochromatographic column.

Embodiment 2

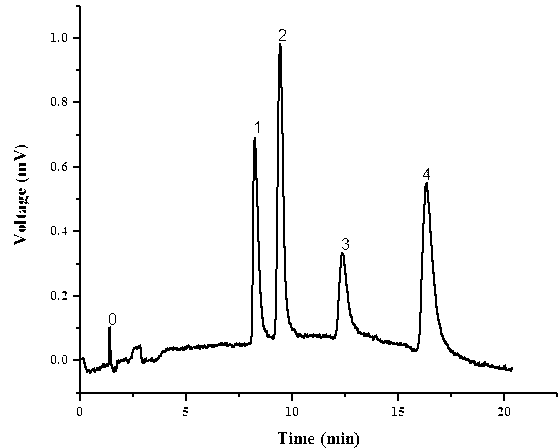

[0021] In CEC mode, pH 5.0, ion concentration 30 mmol / L, acetonitrile:amine formate (85 / 15, v / v) buffer as mobile phase, applied voltage 10 kV, auxiliary pressure 3.5 MPa, pump flow rate 0.1 Under the condition of mL / min, basic nucleosides and base polar compounds can be effectively separated on the polar ion-exchange hybrid silica gel electrochromatographic column, and the peak shape is symmetrical and there is no tailing phenomenon. Its spectrum is as image 3 shown.

Embodiment 3

[0023] In CEC mode, pH 3.5, ion concentration 100 mmol / L, acetonitrile:amine formate (75 / 25, v / v) buffer as mobile phase, applied voltage 20 kV, auxiliary pressure 10.8 MPa, pump flow rate 0.1 Under the condition of mL / min, the nucleotide polar compounds achieved baseline separation on this polar ion-exchange hybrid silica column. Its spectrum is as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com