Nesting doll-shaped manganese oxide nanocrystalline grain composite particle and preparation method thereof

A composite technology of manganese oxide and nanocrystals, applied in the direction of nanotechnology, manganese oxide/manganese hydroxide, etc., can solve the problems of increased removal steps, low specific surface area, cumbersome process, etc., and achieve reduced crystal nucleus concentration, high ratio Surface area, effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

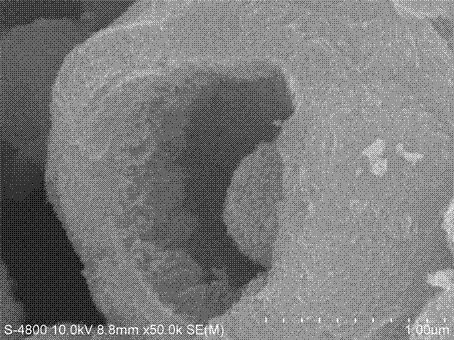

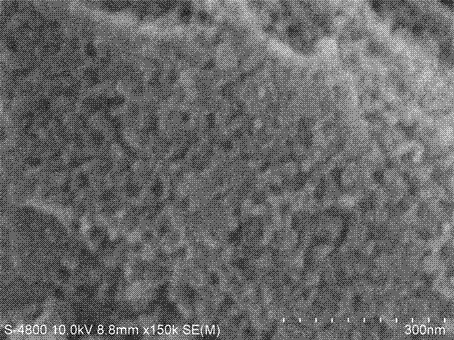

[0021] Dissolve 1 mole of anhydrous manganese sulfate in 800g of water, and 1.2 moles of ammonium bicarbonate in 800g of water; then simultaneously add the two liquids into a container with 120 rpm stirring and ultrasonic frequency of 40KHz, and the ultrasonic power is 100 watts / liter of reaction solution, precipitate reaction at normal temperature for 1 hour, separate the material and liquid, collect the solid material and dry it in the air to obtain a beige ultrafine powder; XRD test results show that the beige ultrafine powder is a composite of manganese carbonate nanocrystals Particles, the size of the nanocrystalline particles is about 12nm; SEM photos show that the obtained manganese carbonate nanocrystalline composite particles are particles with a narrow particle size distribution of 0.7-4 μm.

[0022] The obtained spherical manganese carbonate nanocrystalline composite particles were calcined in an air atmosphere at a temperature of 370° C. for 21 minutes to obtain a...

Embodiment 2

[0025] The manganese carbonate nanocrystalline composite particles prepared in Example 1 were calcined in an air atmosphere at a calcining temperature of 780° C. for 5 to 7 minutes to obtain a dark brown-red powder. SEM photos show that the obtained sample maintains a matryoshka-like structure and the particle size is basically unchanged, with irregular mesopores of about 5-30nm; XRD test results show that it is Mn 2 o 3 JCPDS#71-0636 and Mn 3 o 4 The mixture of JCPDS#80-0382, the BET specific surface area is 65m 2 / g, the fluidity angle of repose is 19°.

Embodiment 3

[0027] The manganese carbonate nanocrystalline composite particles prepared in Example 1 were calcined in an air atmosphere at a calcining temperature of 960° C. for 7 to 12 minutes to obtain a dark brown-red powder. The SEM photos show that the obtained sample maintains a matryoshka-like structure and the particle size is basically unchanged, with irregular mesopores of about 5-50 nm and a small amount of macropores of 70-120 nm; XRD test results show that it is Mn 3 o 4 JCPDS#80-0382 nanocrystalline, the grain size is about 45nm, and the BET specific surface area is 33m 2 / g, the fluidity angle of repose is

[0028] 22°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com