Heat-radiation anticorrosion paint of magnesium alloy LED shell and preparation method thereof

A technology of anti-corrosion coatings and magnesium alloys, which is applied in coatings, devices for coating liquids on surfaces, etc., can solve problems such as weak protection ability, low bonding force of metal coatings, and easy oxidation, so as to prevent primary battery corrosion, Maintain the effect of persistence and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

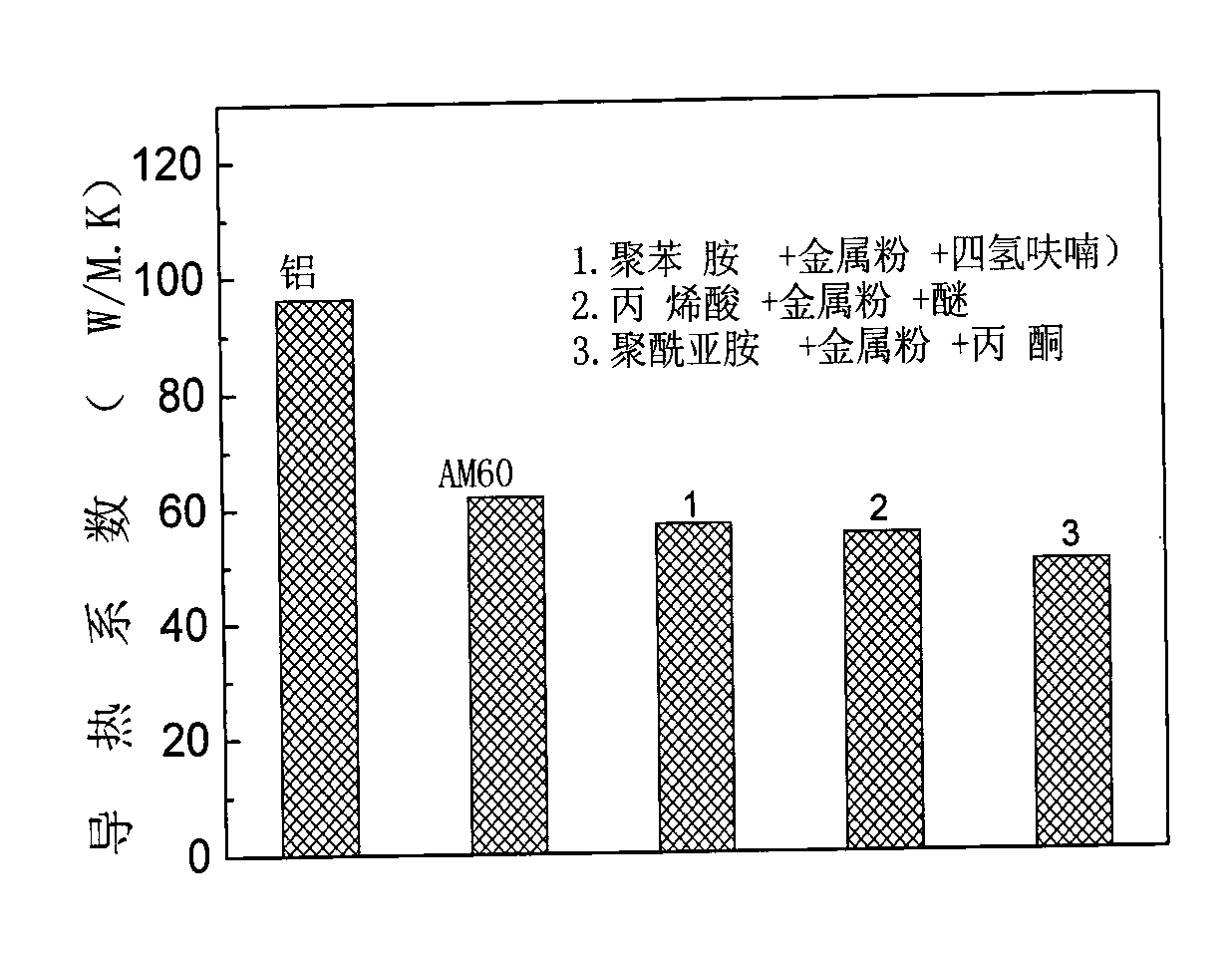

[0022] Take 10 g of yttrium-rich rare earth and 990 g of aluminum ingot, remove the surface oxide scale from the aluminum ingot, use a tantalum crucible and protect it with argon gas, and prepare an alloy ingot in a resistance furnace. Add aluminum ingot first, then add samarium-rich rare earth, fully preheat at 200 ℃ before adding, and stir for 10 minutes for each raw material added, after all raw materials are added, fully stir for 20 minutes, and pour into the steel mold at 450 ℃ . Then, the obtained alloy was atomized into 100-mesh powder at 500 °C under the protection of argon.

[0023] Take 100g of the above-mentioned alloy powder, 800g of polyaniline resin, and 100g of tetrahydrofuran solvent, mix them evenly, and stir for 120 minutes to obtain a heat-dissipating and anti-corrosion coating for a magnesium alloy LED shell.

[0024] When in use, raise the temperature of the above-mentioned paint to 150°C, add it into a high-pressure spray gun, and spray the paint onto th...

Embodiment 2

[0027] Take 200 g of lanthanum-cerium-rich mixed rare earth powder and 800 g of aluminum ingot. After removing the surface scale of the aluminum ingot, use a tantalum crucible and protect it with argon to prepare an alloy ingot in a resistance furnace. Add aluminum ingot first, then add samarium-rich rare earth, fully preheat at 400 ℃ before adding, stir for 30 minutes for each raw material added, after all raw materials are added, fully stir for 20 minutes, and pour into the steel mold at 500 ℃ . Then, the obtained alloy was atomized into 300-mesh powder at 600 °C under the protection of argon.

[0028] Take 800g of the above-mentioned alloy powder, 100g of polyimide resin, and 100g of acetone solvent, mix them evenly, and stir for 300 minutes to obtain a heat-dissipating and anti-corrosion coating for a magnesium alloy LED shell.

[0029] When in use, raise the temperature of the above paint to 200°C, put it into a high-pressure spray gun, and spray the melt onto the prehea...

Embodiment 3

[0033] Take 100 g of samarium-rich rare earth and 900 g of aluminum ingot, remove the surface scale from the aluminum ingot, use a tantalum crucible and protect it with argon gas, and prepare an alloy ingot in a resistance furnace. Add aluminum ingot first, then add samarium-rich rare earth, fully preheat at 300 ℃ before adding, stir for 20 minutes for each raw material added, after all raw materials are added, fully stir for 20 minutes, and pour into the steel mold at 480 ℃ . Then, the obtained alloy was atomized into 200-mesh powder at 550 °C under the protection of argon.

[0034] Take 300g of the above-mentioned metal powder, 600g of acrylic resin, and 100g of ether solvent, mix them evenly, and stir for 200 minutes to obtain a heat-dissipating and anti-corrosion coating for a magnesium alloy LED shell.

[0035] When in use, raise the temperature of the above paint to 170°C, put it into a high-pressure spray gun, and spray the melt onto the preheated magnesium alloy subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com