Acrylic ester pressure-sensitive adhesive for window film

A pressure-sensitive adhesive, acrylate technology, applied in the direction of monocarboxylate copolymer adhesive, adhesive, ester copolymer adhesive, etc. It can solve the problems of poor storage stability of the agent, and achieve the effect of good static electricity conduction, not easy to absorb dust, and flat surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

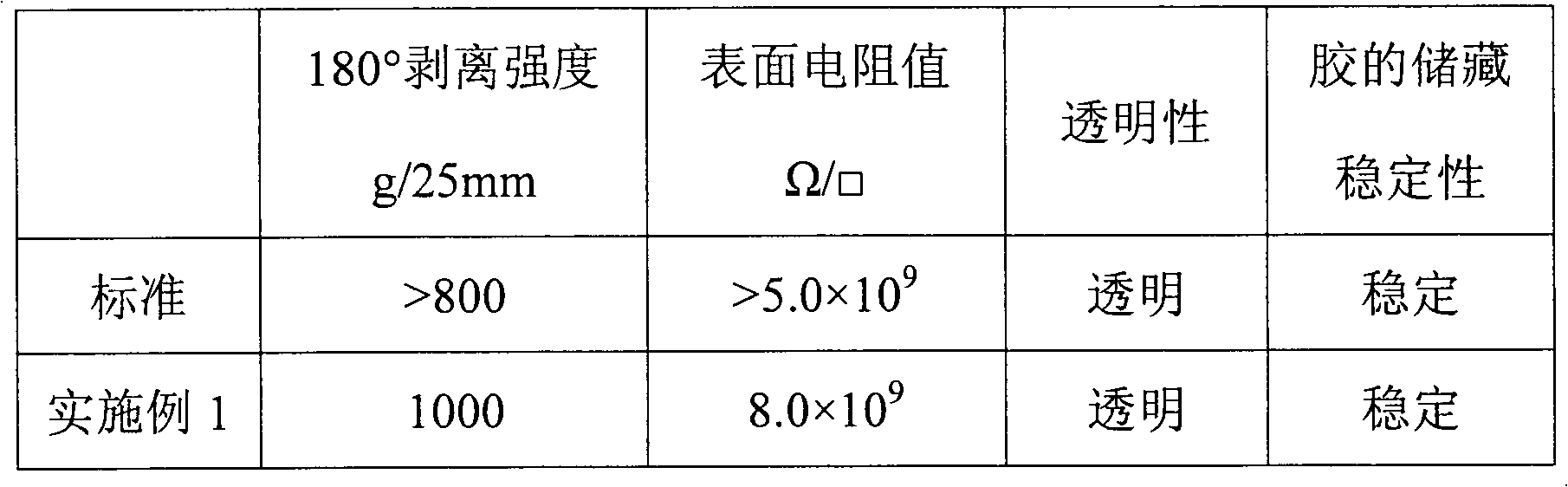

Embodiment 1

[0021] Two parts of raw materials for preparing the acrylate pressure-sensitive adhesive are weighed separately, and the sum of the components of the two parts of the raw materials is within the range of the mass ratio percentage of each raw material component set. In a 1000ml four-neck flask equipped with a thermometer, a reflux condenser and a dropping funnel, add the first raw material components, the acrylate monomers contained: by mass percentage, there are 1.6% acrylic acid, 2-ethylhexyl acrylic acid 5.8% of ester, 1.3% of hydroxyethyl acrylate and 3.2% of methyl methacrylate; functional monomer: by mass percentage, there is 0.3% of glycidyl methacrylate, polymerizable surface active monomer: by mass percentage, Contains 1.0% of polymerizable monoquaternary ammonium cationic surfactant; initiator: 0.16% of azobisisobutyronitrile by mass percentage; solvent: 16.1% of methanol and 14.7% of ethyl acetate by mass percentage. The temperature of the first raw material componen...

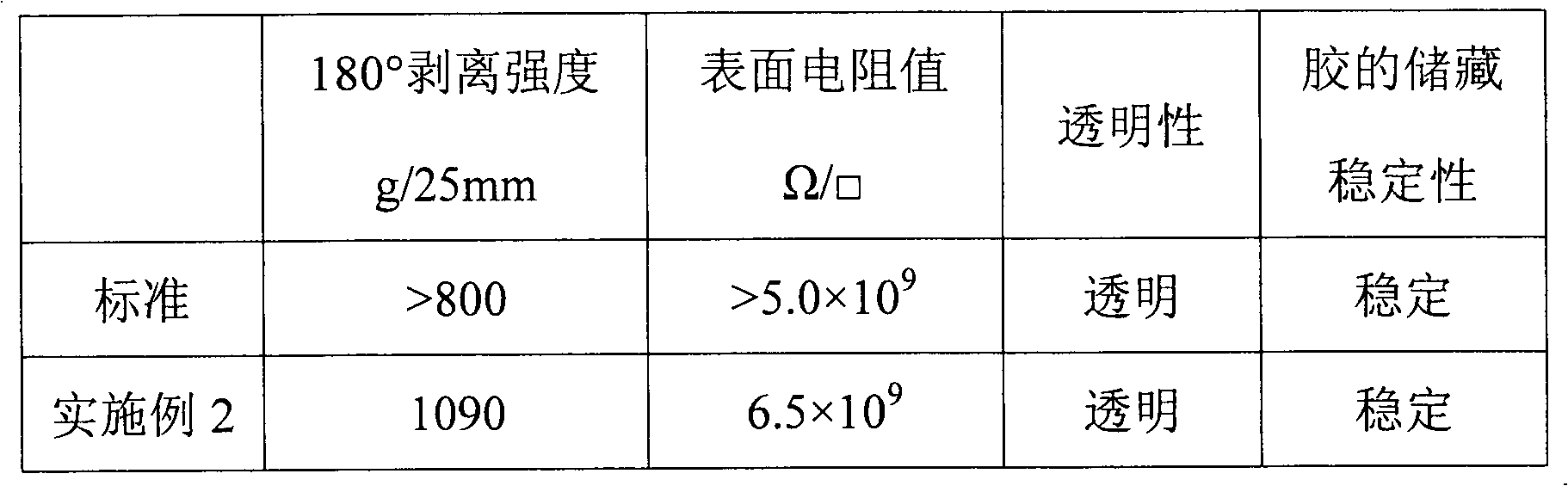

Embodiment 2

[0025] Two parts of raw materials for preparing the acrylate pressure-sensitive adhesive are weighed separately, and the sum of the components of the two parts of the raw materials is within the range of the mass ratio percentage of each raw material component set. In a 1000ml four-necked flask equipped with a thermometer, a reflux condenser and a dropping funnel, add the first part of raw material components. The acrylate monomers contained are: by mass percentage, 3.2% acrylic acid, 2-ethylhexyl acrylic acid 3.2% ester, 0.8% hydroxyethyl acrylate, 4.0% methyl methacrylate, 1.4% methyl acrylate, functional monomers: by mass percentage, vinyl acetate 1.0%, surface active monomers: by mass percentage In total, polymerizable monoquaternary ammonium salt cationic surfactant 1.5%, initiator: by mass percentage, azobisisobutyronitrile 0.16%, solvent: by mass percentage, methanol 16.0%, ethyl acetate 8%. Raise the temperature to 55°C, and after reacting for 1-3 hours, slowly add the...

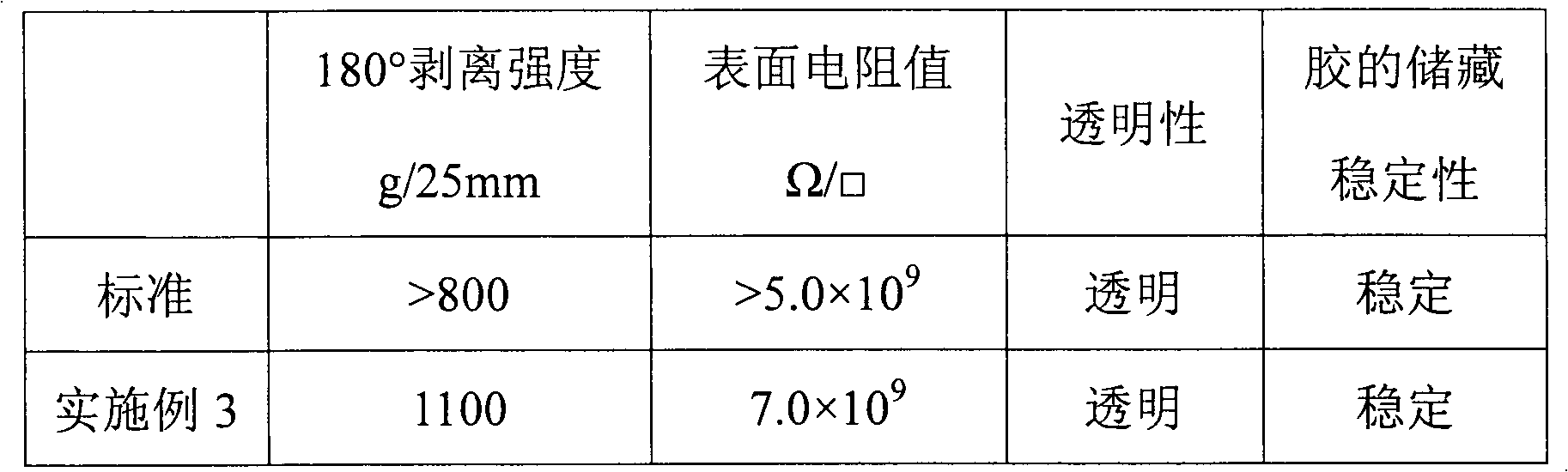

Embodiment 3

[0029] Two parts of raw materials for preparing the acrylate pressure-sensitive adhesive are weighed separately, and the sum of the components of the two parts of the raw materials is within the range of the mass ratio percentage of each raw material component set. In a 1000ml four-necked flask equipped with a thermometer, a reflux condenser and a dropping funnel, add the first raw material components. The acrylate monomers contained are: by mass percentage, 3.2% acrylic acid, 2-ethylhexyl acrylic acid 3.2% ester, 0.8% hydroxyethyl acrylate, 4.0% butyl acrylate, 1.4% methyl acrylate, functional monomers: by mass percentage, acrylonitrile 1.0%, surface active monomers: by mass percentage, can Polymerized diquaternary ammonium salt cationic surfactant 1.5%, initiator: by mass percentage, benzoyl peroxide 0.16%, solvent: by mass percentage, methanol 16.0%, ethyl acetate 8%. Raise the temperature to 55°C, and after reacting for 1-3 hours, slowly add the second raw material compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com