Method for preparing soluble corn peptide from Aspergillus niger fermented maize yellow powder

A technology for fermentation of Aspergillus niger and corn yellow powder, applied in the field of food biochemical industry, can solve the problems of many side reactions, high cost and high price, and achieve the effects of low cost, few by-products and high water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

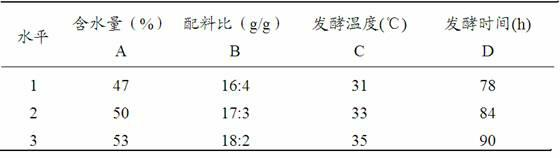

Method used

Image

Examples

Embodiment 1

[0032] (1) Raw material pretreatment Weigh 2 portions of 50g corn yellow powder and divide them into two 1000mL beakers, add 800mL 16mL / g Na 2 CO 3Soak in the solution for 10 minutes at 40°C, centrifuge and wash, and dry the filter residue in an oven at 50°C. Thereafter, the suspension was prepared according to the solid-to-liquid ratio of corn yellow powder and water at a ratio of 1:5, and 5% high-temperature-resistant α-amylase was added, and the enzyme was hydrolyzed in a shaker at 60°C and 150 r / min until the iodine solution was added. Turning blue indicates complete enzymatic hydrolysis. After centrifugation and washing for 10 times, the corn yellow powder is dried in an oven at 50°C.

[0033] (2) Fermentation culture Accurately weigh 1g of sucrose, K 2 HPO 4 0.04g, the mass ratio of corn yellow powder (after destarching) to bran is 16:4 (total 20g), the amount of water added is 53% of the total mass of the medium (mass ratio), in a 250mL Erlenmeyer flask, 121°C Ste...

Embodiment 2

[0037] (1) Raw material pretreatment Weigh 2 portions of 50g corn yellow powder and divide them into two 1000mL beakers, add 800mL 16mL / g Na 2 CO 3 Soak in the solution for 10 minutes at 40°C, centrifuge and wash, and dry the filter residue in an oven at 50°C. Thereafter, the suspension was prepared according to the solid-to-liquid ratio of corn yellow powder and water at a ratio of 1:5, and 5% high-temperature-resistant α-amylase was added, and the enzyme was hydrolyzed in a shaker at 60°C and 150 r / min until the iodine solution was added. Turning blue indicates complete enzymatic hydrolysis. After centrifugation and washing for 10 times, the corn yellow powder is dried in an oven at 50°C.

[0038] (2) Fermentation culture Accurately weigh 1g of sucrose, K 2 HPO 4 0.04g, the mass ratio of corn yellow powder (after destarch) to bran is 18:2 (20g in total), the amount of water added is 53% of the total mass of the medium (mass ratio), in a 250mL Erlenmeyer flask, 121°C St...

Embodiment 3

[0042] (1) Raw material pretreatment Weigh 2 portions of 50g corn yellow powder and divide them into two 1000mL beakers, add 800mL 16mL / g Na 2 CO 3 Soak in the solution for 10 minutes at 40°C, centrifuge and wash, and dry the filter residue in an oven at 50°C. Thereafter, the suspension was prepared according to the solid-to-liquid ratio of corn yellow powder and water at a ratio of 1:5, and 5% high-temperature-resistant α-amylase was added, and the enzyme was hydrolyzed in a shaker at 60°C and 150 r / min until the iodine solution was added. Turning blue indicates complete enzymatic hydrolysis. After centrifugation and washing for 10 times, the corn yellow powder is dried in an oven at 50°C.

[0043] (2) Fermentation culture Accurately weigh 1g of sucrose, K 2 HPO 4 0.04g, the mass ratio of corn yellow powder (after destarching) to bran is 18:2 (20g in total), the amount of water added is 47% of the total mass of the medium (mass ratio), in a 250mL Erlenmeyer flask, 121°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com