System and method for supercritical water oxidation treatment and resource utilization of organic sludge

A technology of supercritical water oxidation and organic sludge, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of high transportation cost, large one-time investment, and few disposal process links, etc. problems, to achieve the effect of high power generation efficiency and major social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

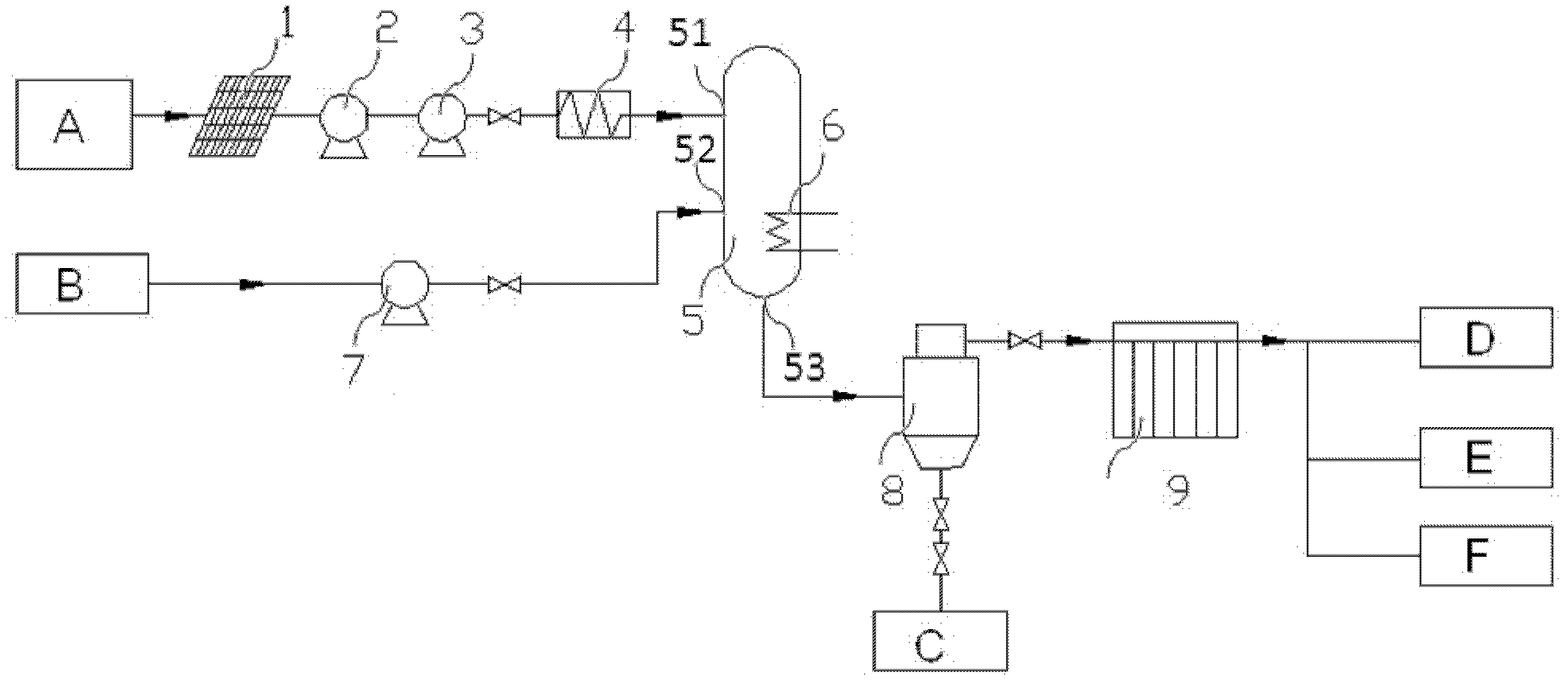

[0038] Such as figure 1 The supercritical water oxygen treatment and resource utilization system of organic sludge includes grid 1, sludge mixing crusher 2, sludge pressure pump 3, preheater 4, supercritical water oxidation reactor 5, oxidant pressure Pump 7, high pressure hydrocyclone 8 and supercritical generator set 9. Grille 1, sludge mixing crusher 2, sludge pressure pump 3 and preheater 4 are connected sequentially through the delivery pipeline, the output port of preheater 4 is connected to the input port 51 of supercritical water oxidation reactor, and the oxidant pressure pump 7 is connected to the oxidant input port 52 of the supercritical water oxidation reactor 5. A heater 6 is installed in the supercritical water oxidation reactor. The output port 53 of the supercritical reactor is connected to the inlet of the high-pressure hydrocyclone 8, the fluid outlet of the high-pressure hydrocyclone 8 is connected to the supercritical generator set 8, and the output por...

Embodiment 2

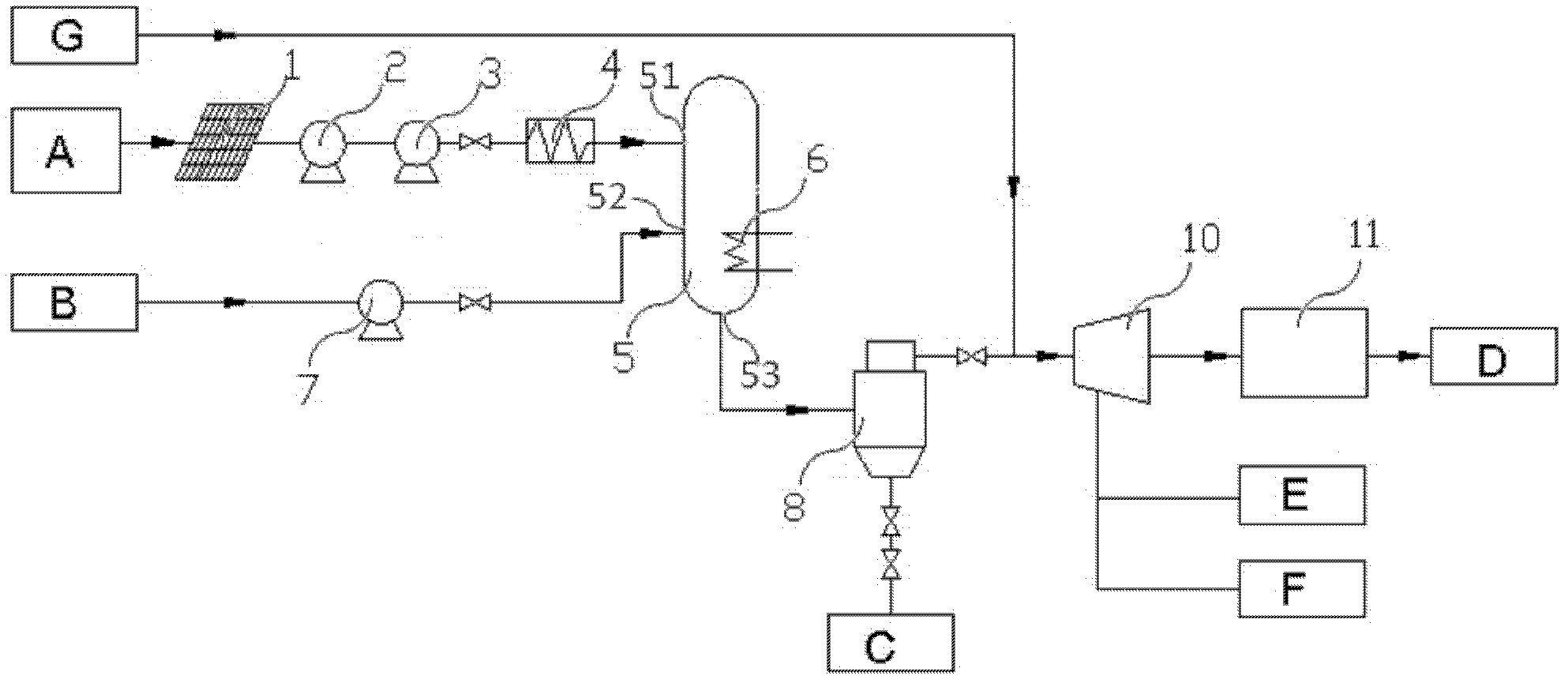

[0049] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the power generation system is composed of a steam turbine 10, a steam generator set 11, a cold water pump 12, a grid D, a heating device E and a refrigeration device F; the steam turbine 10 high-temperature steam outlet and The input end of the steam generating set 11 is connected, and the output of the steam generating set 11 is connected to the power grid D in sequence; the 10 high-temperature steam outlets of the steam turbine are respectively connected to the heating device E and the cooling device F; the cold water pump 12 passes through the pipeline and the high-pressure hydrocyclone 8 Supercritical water outlet connection. The supercritical water discharged from the high-pressure hydrocyclone 8 is not used for supercritical power generation, but is turned into steam by adding cold water G to reduce the temperature and pressure, and then use the steam turbine to generate e...

Embodiment 3

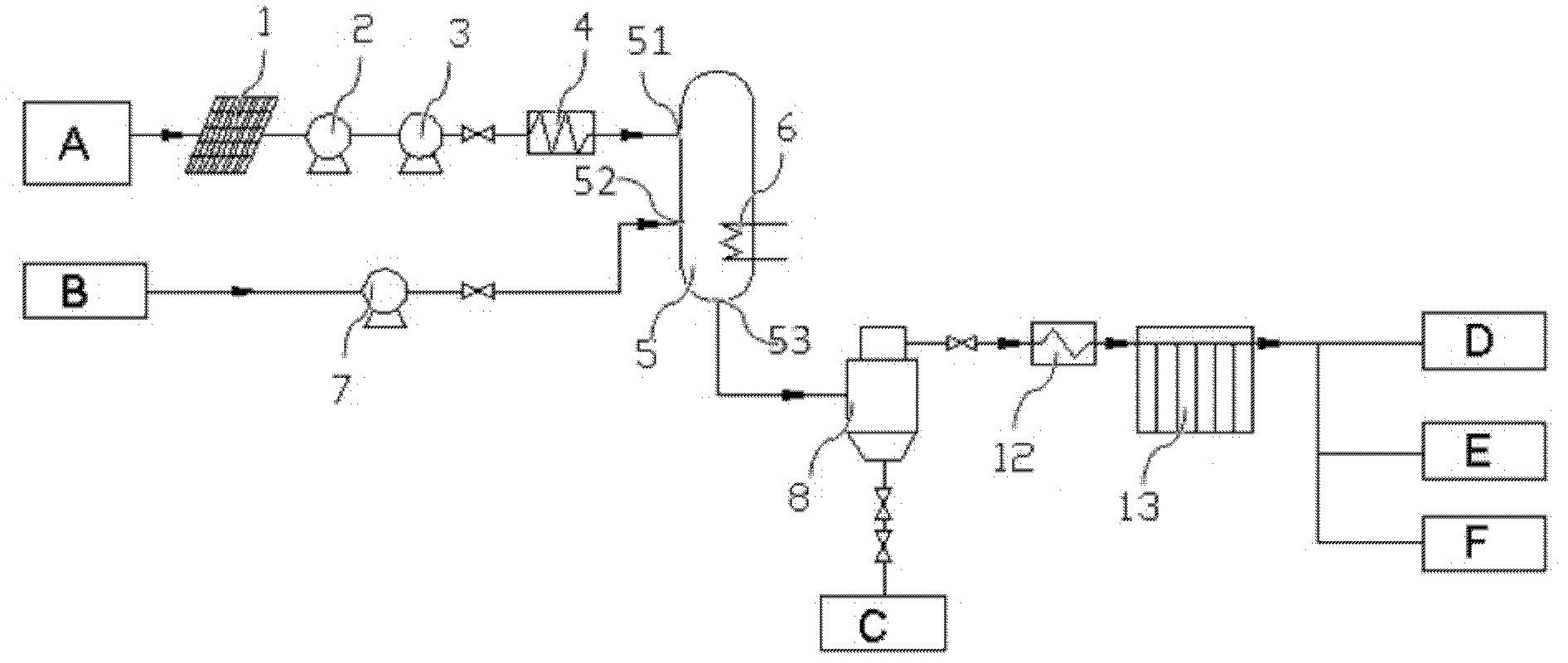

[0060] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that a heater 12 is provided at the supercritical water outlet of the high-pressure hydrocyclone 8 and the input of the supercritical generator set, and the supercritical water discharged from the high-pressure hydrocyclone 8 is not Directly perform supercritical power generation, but continue heating through the heater 12 to make the temperature reach above 580°C and the pressure at 30~40MPa, and then use it for supercritical power generation, so as to further improve the power generation efficiency, and use the back pressure steam after power generation For heating or cooling.

[0061] The method for supercritical water oxygen treatment and resource utilization of organic sludge comprises the following steps:

[0062] (1) Use the grid 1 to perform coarse filtration of the sludge to be treated to remove the large pieces and strips;

[0063] (2) Use the sludge stirring crusher 2 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com