Method and equipment for recovery of oilfield associated gas hydrocarbon mixture

A technology for oilfield associated gas and recovery method, which is applied in the field of oilfield associated gas mixed hydrocarbon recovery equipment, and can solve the problems of insufficient attention to molecular sieve dehydration, improper handling or operation, potential safety hazards, and production delays, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

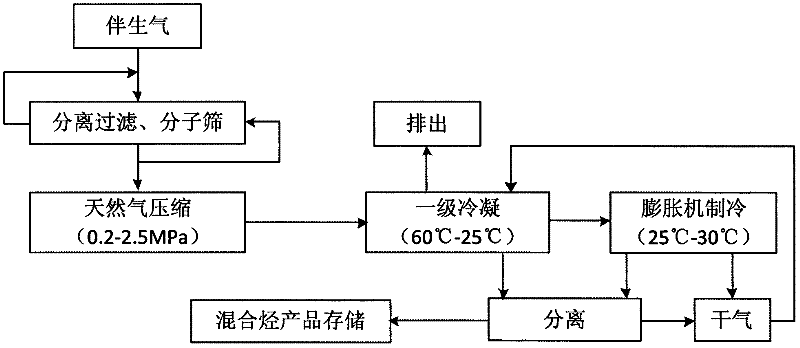

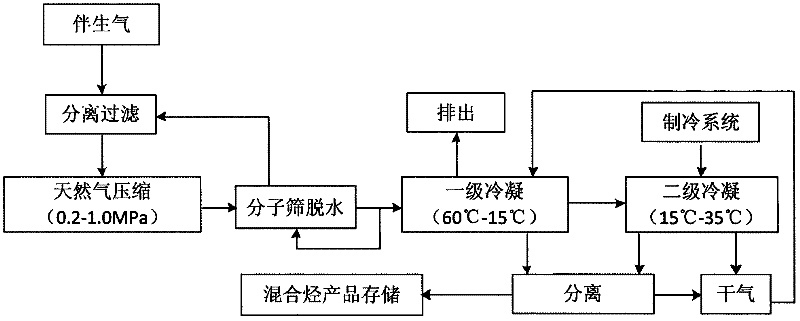

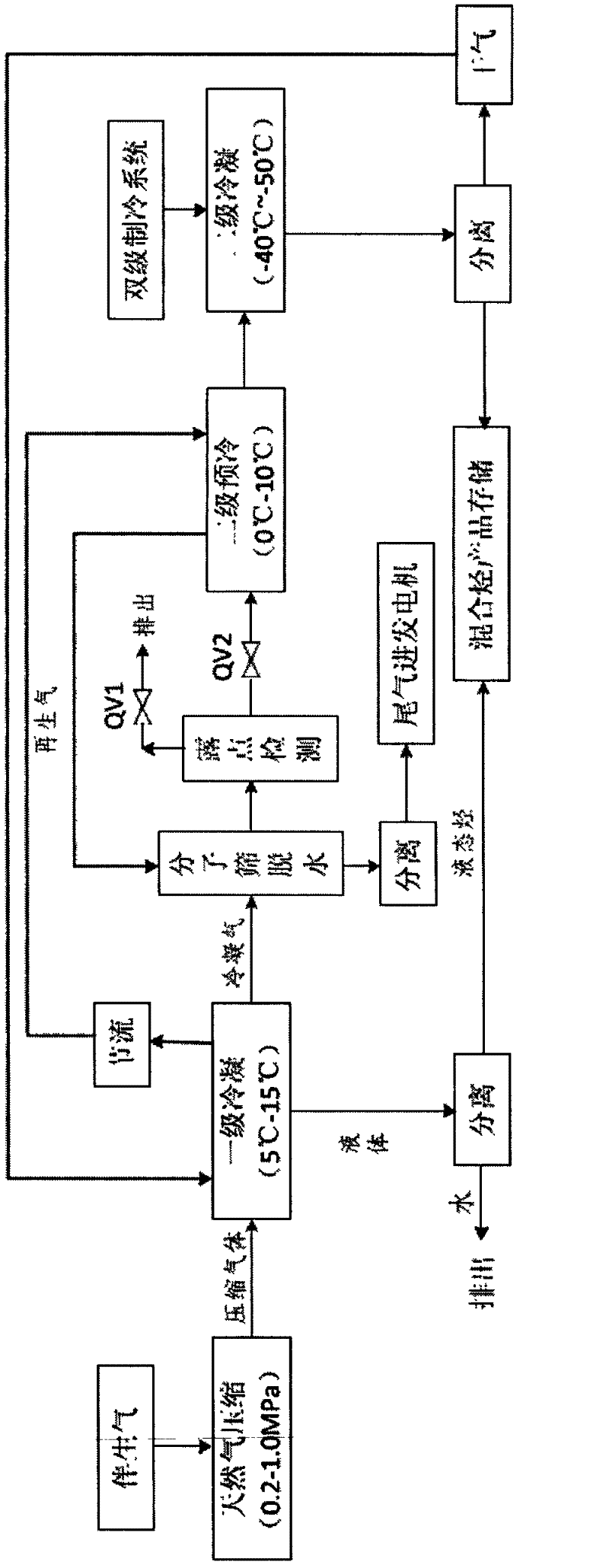

[0034] Combine below image 3 The preferred recovery method and recovery equipment of the present invention are further described.

[0035] The oilfield associated gas mixed hydrocarbon recovery method of the present invention comprises the following steps:

[0036] Step 1: The associated gas is transported to the compressor for compression to form a compressed gas with a pressure of P1;

[0037] Step 2: The compressed gas is subjected to primary condensation at temperature T1 to form condensed gas and liquid substances;

[0038] Step 3: The condensed gas is transported to molecular sieves for dehydration;

[0039] Step 4: Dew point detection of dehydrated condensed gas;

[0040] Step 5: If the dew point temperature of the dehydrated condensed gas is higher than the temperature T2, discharge it to form recycled regeneration gas.

[0041] In the step 5, if the dew point temperature of the dehydrated condensed gas is lower than the temperature T2, the recovery method further i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com