Molybdenum-doped tungsten diselenide nanosheet serving as anti-fraction additive and preparation method thereof

A friction-reducing additive, tungsten diselenide technology, applied in additives, petroleum industry, lubricating compositions, etc., can solve the problems of environmental pollution, complex process control, etc. Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

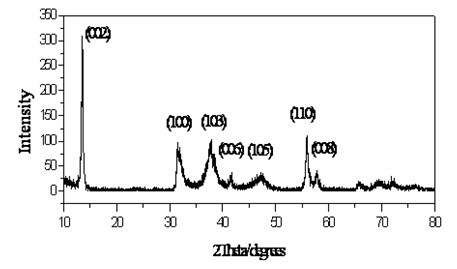

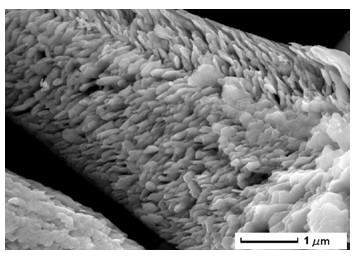

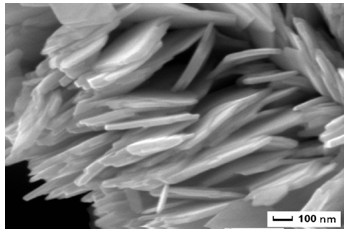

[0018] Weigh the Mo powder, W powder and Se powder in a ratio of 5:95:220 in the amount of the substance. Mo powder 0.068g, W powder 2.48g, Se powder 2.71g, and the ball to material ratio 10:1 Put 50g stainless steel balls (diameter 6mm) together with the powder to be reacted into the clean stainless steel tank of the ball mill, cover and seal, and extract the air in the tank and then pour in Ar gas. Repeat 5 times to ensure that the air in the tank is fully discharged . Ball mill on planetary ball mill for 10h (ball mill rotation speed 200rpm). Take out the reactant from the ball milling pot and place it in the reactor for sealing, take out the air in the reactor, and pass in Ar gas, repeat 5 times, put it into the tubular reactor and heat it to 600℃ at a rate of 7℃ / min and keep it warm 1h, cool down to room temperature with the furnace, take out the powder from the reactor to obtain lamellar WSe 2 nanomaterials.

[0019] The product is tested, the X-ray energy spectrum (EDS) ...

Embodiment 2

[0021] Weigh the Mo powder, W powder and Se powder in a ratio of 3:97:220 in the amount of the material. Mo powder 0.045g, W powder 2.78g, Se powder 2.71g, and the ball-to-material ratio 10:1 Put 50g stainless steel balls (diameter 6mm) together with the powder to be reacted into the clean stainless steel tank of the ball mill, cover and seal, and extract the air in the tank and then pour in Ar gas. Repeat 5 times to ensure that the air in the tank is fully discharged . Ball mill on planetary ball mill for 10h (ball mill rotation speed 200rpm). Take out the reactant from the ball milling jar and place it in the reaction kettle for sealing. Take out the air in the reaction kettle and pass in Ar gas. Repeat 5 times. Put it into a tubular reactor and heat it to 650°C at a rate of 7°C / min. 1.5g, cooled to room temperature with the furnace, take out the powder from the reactor to obtain lamellar WSe 2 nanomaterials.

[0022] The prepared molybdenum-doped tungsten diselenide nanoshee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com