Spiral-wound automotive permeable membrane module and preparation method thereof

A permeable membrane and spiral-wound technology, applied in the field of spiral-wound separation membrane modules and their preparation, can solve the problems of low separation efficiency and heavy equipment, and achieve the effects of uniform gas distribution, easy rolling operation and high packing density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: The preparation process of a spiral-wound gas permeation membrane module with a diameter of 4.

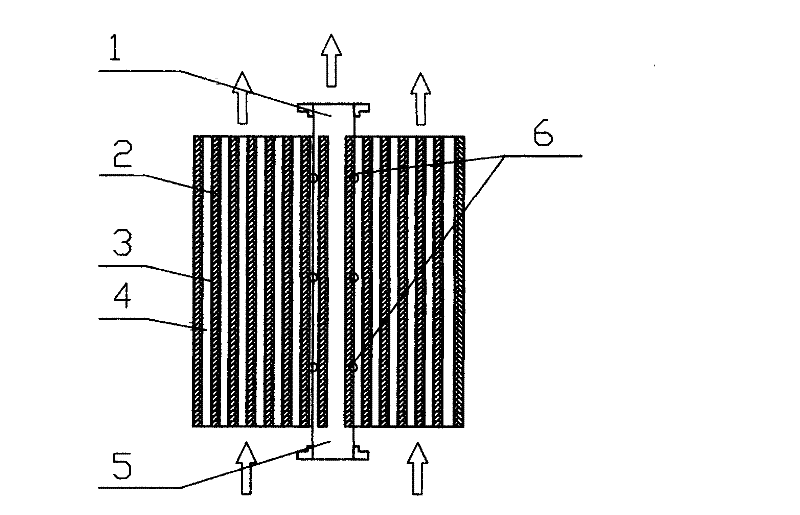

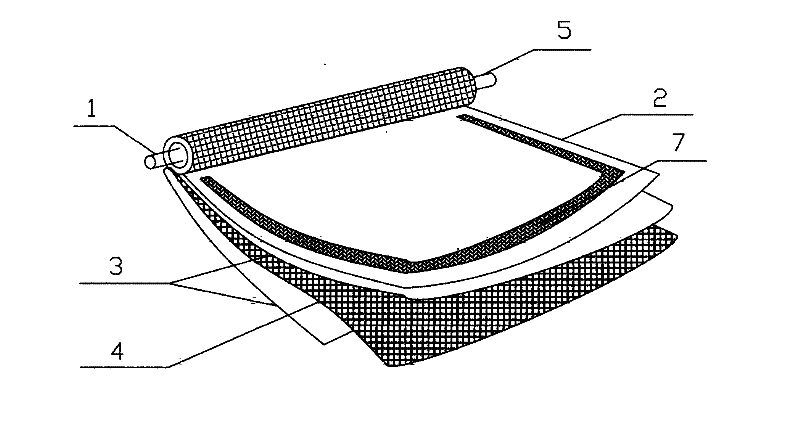

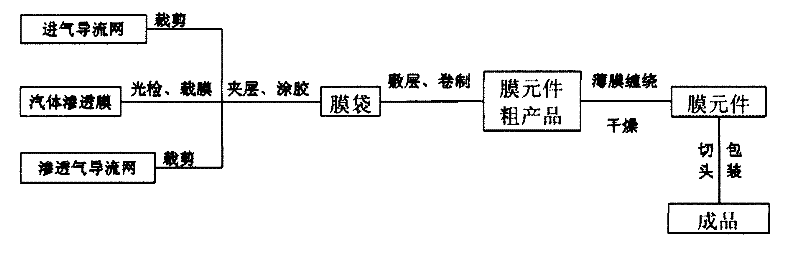

[0022] figure 1 It is a schematic diagram of the overall structure of the spiral-wound gas permeation membrane module of the present invention; figure 2 It is a schematic diagram of the assembly of the diaphragm, spacer and central tube of the spiral wound gas permeation membrane module of the present invention. The main body of the membrane module is composed of a central tube (1), a diaphragm (3), an air intake diversion layer (2), and a permeate diversion layer (4). The diaphragm (3) is folded into two facing opposite diaphragms , a layer of thicker grid guide net is entrained in the middle as the intake guide layer, and a layer of denser grid guide net is entrained on the back of the diaphragm as the permeate gas guide layer. The side and outer end are glued and the upper and lower layers are opposite to the back to form a membrane bag, in which the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com