Two-phase stainless steel welding electrode and manufacturing method thereof

A technology of duplex stainless steel and electric welding rod, applied in the direction of manufacturing tools, welding medium, welding equipment, etc., can solve the problems of difficulty in taking into account mechanical properties and welding manufacturability at the same time, and achieve good slag removal, beautiful weld formation, and mechanical properties. and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the examples.

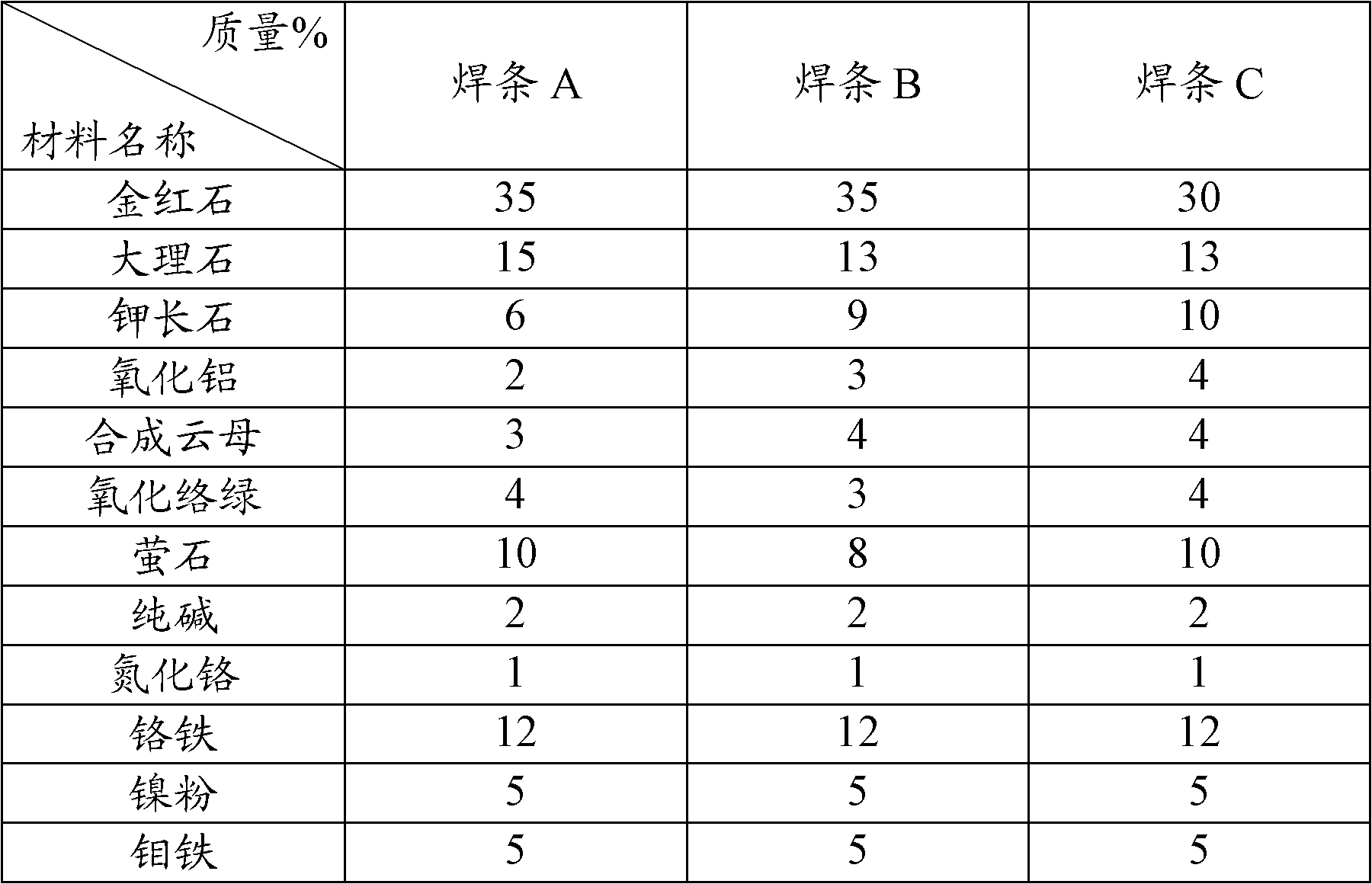

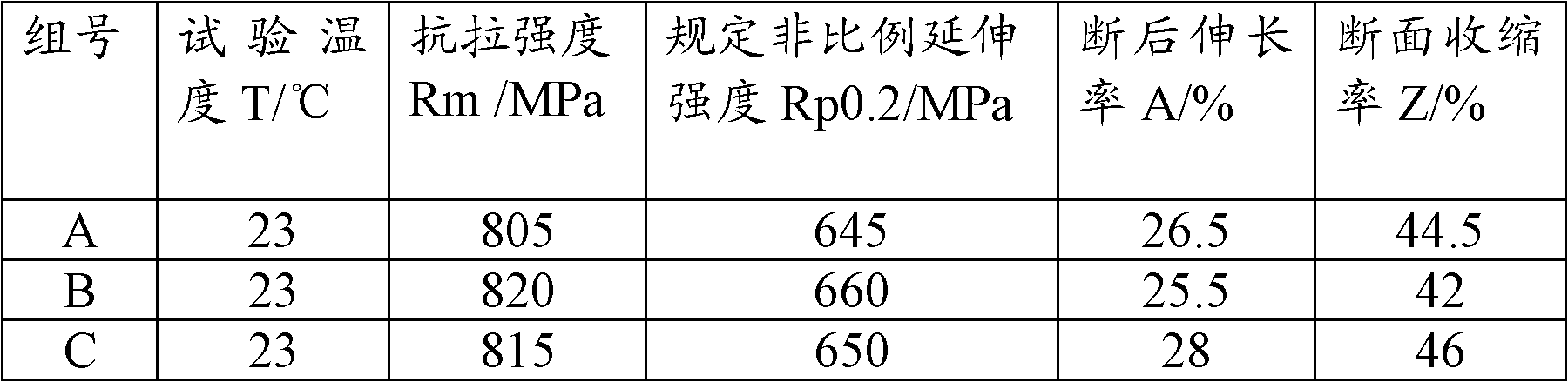

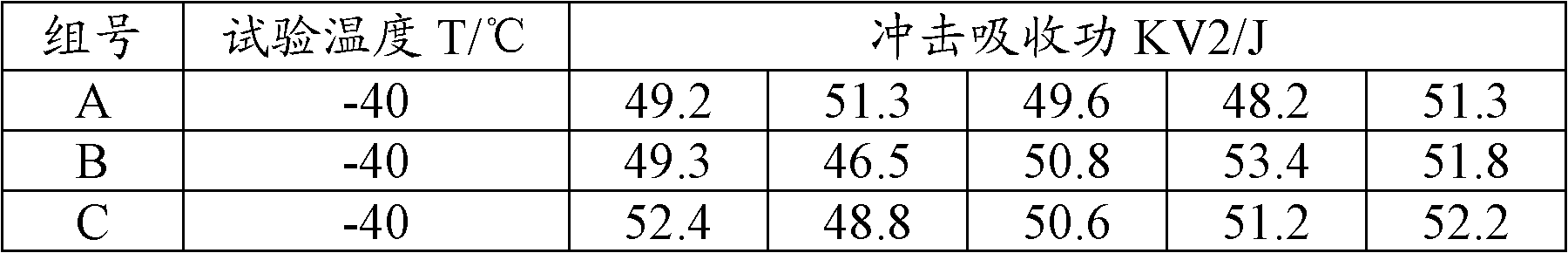

[0026] Composition according to the drug skin of proportioning that the present invention adopts, has made A, B, C three groups of welding electrodes, specifically as follows:

[0027] Raw material ratio of welding rod:

[0028]

[0029] Weigh the above-mentioned coating components of the three proportions of A, B, and C respectively, and after mixing, add potassium-type water glass accounting for 20% to 22% of the total weight of the coating, with a pomi degree of 43°, and stir evenly , coated on the outside of the welding core, pressed by a hydraulic press, and then dried at 350°C for 2 hours at a high temperature to obtain three kinds of welding electrodes A, B, and C.

[0030] The ferrochrome is selected as FeCr65C0.03 conforming to GB5683-2008, and its chemical composition is as follows: Cr≥60.0wt%, Si≤1.0wt%, S≤0.025wt%, P≤0.03wt%, C≤0.03wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com