Polyaniline nanowire/ graded porous carbon composite material as well as preparation method and application thereof

A carbon composite material, graded porous technology, used in capacitors, circuits, electrolytic capacitors, etc., can solve problems such as hindering application and poor cycle stability, and achieve the effect of increasing capacitance performance, good specific energy density, and easy availability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

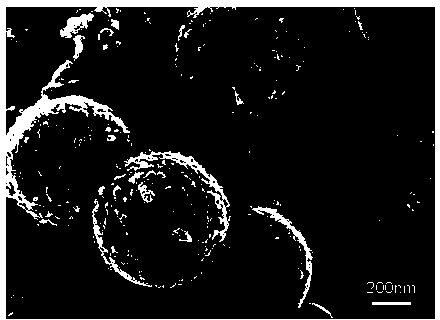

[0041] Weigh 0.2g of the hollow mesoporous silicon / carbon composite prepared in the above step (3), put it into 15ml of 1M perchloric acid solution and sonicate for 30 minutes to fully disperse the hollow mesoporous silicon sphere / carbon composite, add 27.4μL of aniline monomer Continue to sonicate for 10 minutes. Weigh 0.069g of ammonium persulfate and dissolve it in 15ml of 1M perchloric acid solution, place it in the refrigerator for a period of time and slowly add it dropwise to the above mixed solution, stir and react in the ice-water bath for 24 hours, after washing and drying A black powder was obtained. Finally, the hollow mesoporous silicon sphere template was removed with 5% hydrofluoric acid to obtain a polyaniline nanowire / hierarchical porous carbon composite. Electron microscope photographs of the product figure 1 shown.

Embodiment 2

[0043] Weigh 0.2g of the hollow mesoporous silicon sphere / carbon composite prepared in the above step (3), put it into 15ml of 1M perchloric acid solution and ultrasonically disperse the hollow mesoporous silicon sphere / carbon composite for 30 minutes, add 54.7μL of aniline monomer and continue Sonicate for 10 minutes. Weigh 0.137g of ammonium persulfate and dissolve it in 15ml of 1M perchloric acid solution, place it in the refrigerator for a period of time and slowly add it dropwise to the above mixed solution, stir and react in the ice-water bath for 24 hours, after washing and drying A black powder was obtained. Finally, the hollow mesoporous silicon sphere template was removed with 5% hydrofluoric acid to obtain a polyaniline nanowire / hierarchical porous carbon composite. Electron microscope photographs of the product figure 2 shown.

example 3

[0044] Characterization of Example 3 Polyaniline Nanowire / Hierarchical Porous Carbon Composite

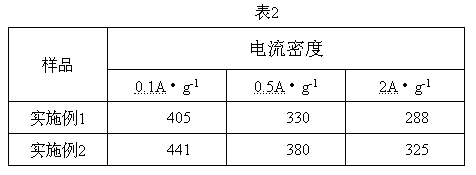

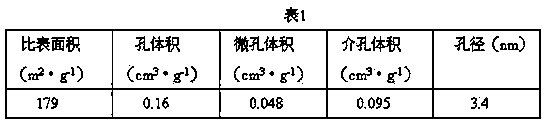

[0045] The specific surface area and pore size distribution of the polyaniline nanowires / hierarchical porous carbon composites prepared in the above-mentioned examples 1 and 2 were analyzed using a field emission electron microscope (HITACHI S4800) and a nitrogen adsorption-desorption analyzer (Micromeritics ASAP 2020) respectively. representation. Table 1 is the specific surface area and pore size distribution curve of the product of Example 2. Table 2 is the specific capacitance performance of the products of Example 1 and Example 2 at different current densities.

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com