Cellulose/inorganic particle composite diaphragm for lithium secondary battery and preparation method thereof

A lithium secondary battery and inorganic particle technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of cellulose paper airtightness, strength, and electrochemical performance that cannot meet the requirements of secondary battery diaphragm materials. , to achieve the effects of good chemical stability, environmentally friendly materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

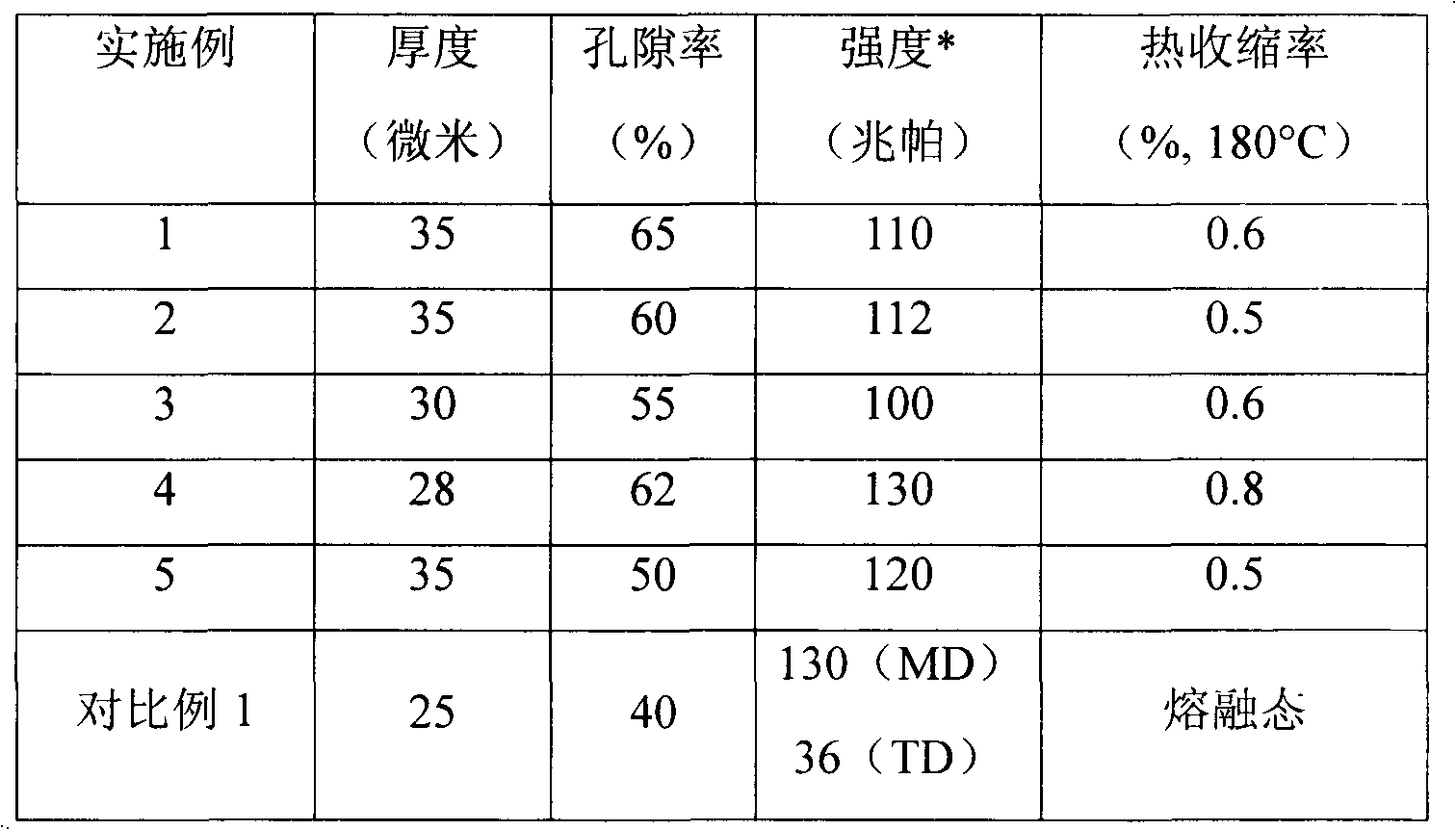

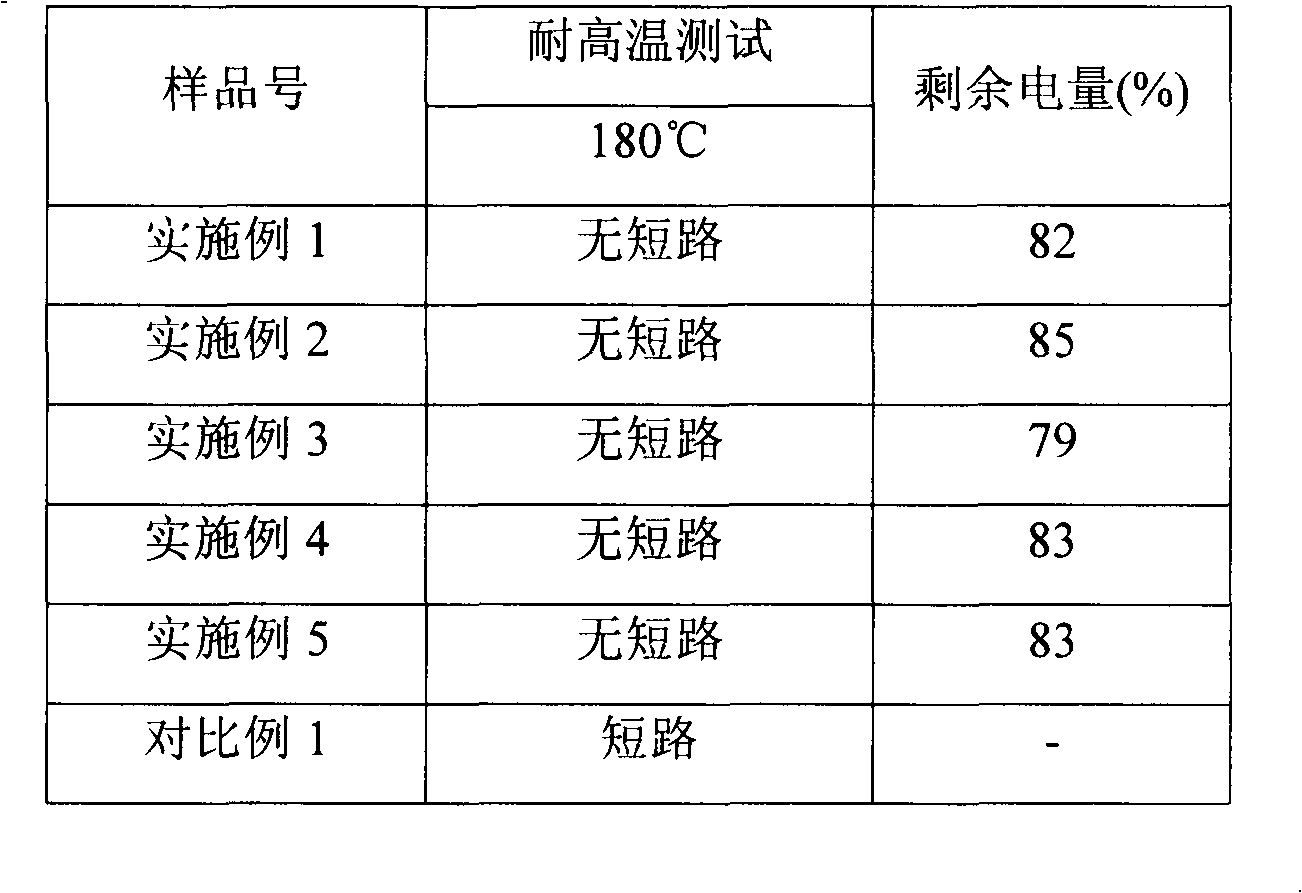

Embodiment 1

[0045] Add 1 liter of distilled water to 20 grams of hardwood pulp (needle kraft pulp), soak and grind at a high speed, beating to make a hardwood plant fiber slurry with a concentration of 2wt%, the CFS value is 600, and the fiber diameter is 0.8 micron. 1 gram of silicon dioxide with a particle size of 50nm is dispersed in 100 ml of water, 0.2 gram of urea-formaldehyde resin is added, and fully mixed with cellulose slurry, paper is made by a semi-automatic paper machine, and the wet paper is removed by squeezing with a press roller excess moisture. Put the rolled wet paper into ethanol, replace the moisture in the wet paper twice with ethanol, and dry at 35°C to make a cellulose composite separator with a thickness of 35 microns.

Embodiment 2

[0047] Add 1 liter of distilled water to 20 grams of hemp pulp, after soaking, through high-speed grinding and beating, make a hardwood plant fiber slurry with a concentration of 2wt%, the CFS value is 500, and the fiber diameter is 0.8 micron. Silica is dispersed in 100 ml of water, 0.2 g of urea-formaldehyde resin is added, and fully mixed with cellulose slurry, paper is made by a semi-automatic paper machine, and the wet paper sheet is squeezed with a press roller to remove excess water. Put the rolled wet paper into acetone, replace the moisture in the wet paper twice with acetone, and dry at 35° C. to prepare a cellulose composite separator with a thickness of 35 μm.

Embodiment 3

[0049] Add 1 liter of distilled water to 20 grams of hardwood pulp (needle kraft pulp), soak and grind at a high speed, beating to make a hardwood plant fiber slurry with a concentration of 2wt%, the CFS value is 300, and the fiber diameter is 0.6 micron. 1 gram of aluminum oxide with a particle size of 500nm is dispersed in 100 milliliters of water, 0.2 grams of melamine formaldehyde resin is added, and fully mixed with cellulose slurry, paper is made by a semi-automatic paper machine, and the wet paper is rolled with a press roll Press to remove excess water. Put the rolled wet paper into ethanol, replace the moisture in the wet paper twice with ethanol, and dry at 35°C to prepare a cellulose composite separator with a thickness of 30 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com