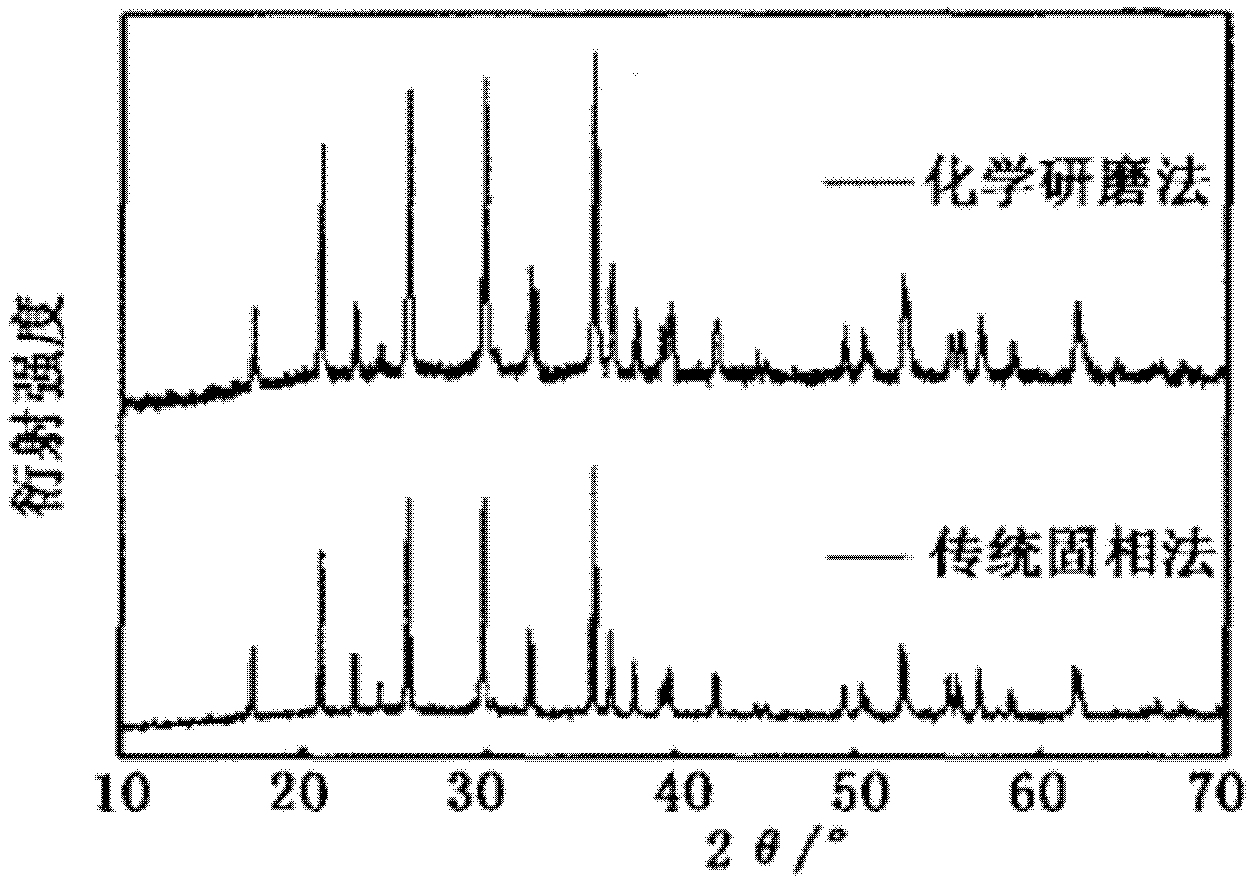

Preparation method of carbon-coated and doped lithium-iron phosphate

A technology of lithium ferrous phosphate and iron source, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of complex solid-liquid phase synthesis conditions, difficult to meet large-scale preparation of materials, etc., and reduce control conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

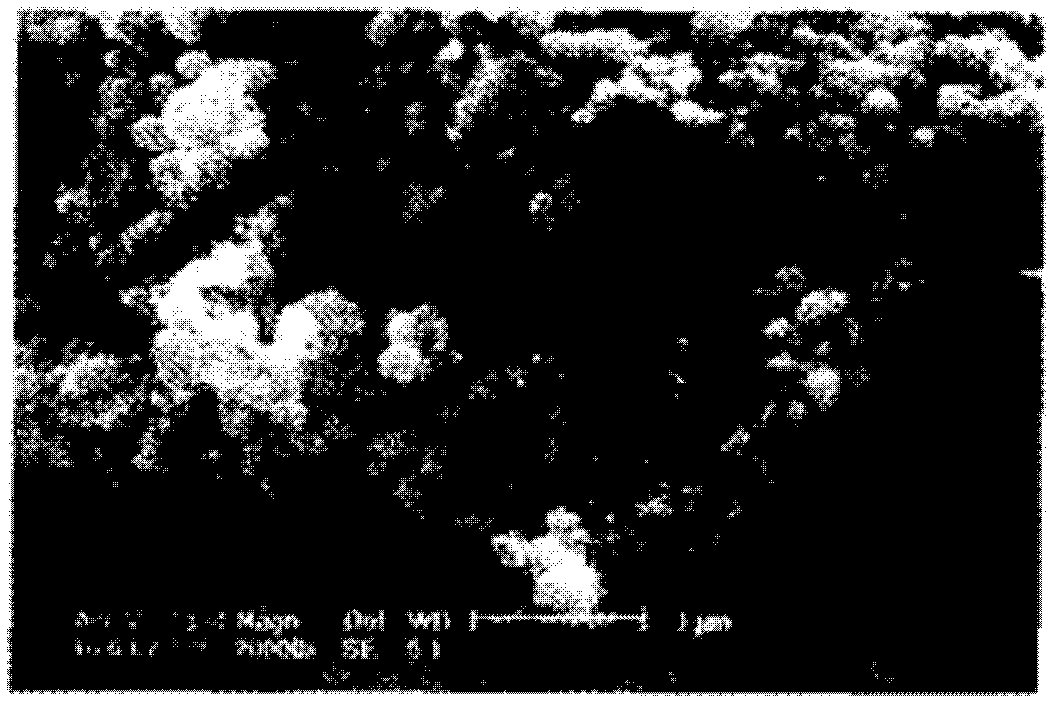

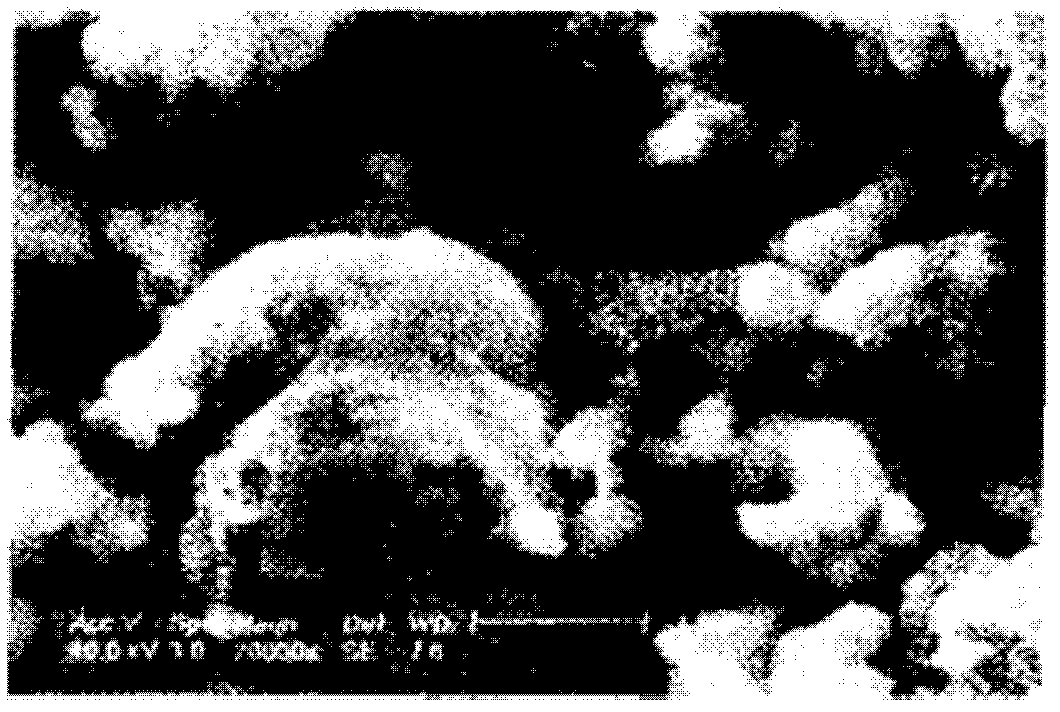

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of carbon-doped lithium iron phosphate comprises the following steps:

[0030] 1) by mass parts, weigh 0.738 parts of Li 2 CO 3 , 4.457 parts FePO 4 , 0.308 parts of glucose, mixed and put into a ball mill tank, ball milled for 2 hours, and mixed evenly;

[0031] 2) Put the mixed powder obtained in step 1) into a high-temperature furnace, heat and calcinate under a nitrogen atmosphere, and the pressure of the furnace cavity is 1.5×10 5 Pa, the temperature is 600°C, calcined for 3 hours;

[0032] 3) Lower the temperature of the high-temperature furnace to 500°C, introduce air, keep warm for 5 hours, then cool down to room temperature, and take out the intermediate product;

[0033] 4) Add 0.308 g of glucose to the mixed powder obtained in step 3), ball mill it for 2 hours after mixing, then put it into the high-temperature furnace again, and calcinate it under a nitrogen atmosphere at a pressure of 1.2×10 5 Pa, the temperature is 700°C, the ca...

Embodiment 2

[0046] The preparation method of carbon-doped lithium iron phosphate comprises the following steps:

[0047] 1) Weigh 1mol of Li 2 CO 3 , 1mol of Fe 2 o 3 , 1mol of ammonium dihydrogen phosphate and 20g of glucose were mixed and put into a ball mill jar, ball milled for 2 hours, and mixed evenly.

[0048] 2) Put the mixed powder obtained in step 1) into a high-temperature furnace and heat it under a nitrogen atmosphere. The pressure of the furnace cavity is 1.5×10 5 Pa, the temperature is 600°C, and the treatment is 3 hours;

[0049] 3) Lower the temperature of the high-temperature furnace to 500° C., introduce air, keep the temperature for 5 hours, and take out the materials when the temperature is lowered to room temperature.

[0050] 4) Add 5 grams of glucose to the mixed powder obtained in step 3), ball mill for 2 hours, put the material back into the high-temperature furnace, and perform high-temperature treatment in a nitrogen atmosphere with a pressure of 1.2×105Pa...

Embodiment 3

[0052] The preparation method of carbon-doped lithium iron phosphate comprises the following steps:

[0053] 1) LiH 2 PO 4 , FeC 2 o 4 , FeO was mixed in a molar ratio of 1: (0.96-0.99): (0.01-0.04) in an equimolar ratio, and 10 grams of sucrose was added.

[0054] 2) Put the mixed powder obtained in step 1) into a high-temperature furnace, heat it under an argon atmosphere for pretreatment, and the pressure of the furnace cavity is 1.5×10 5 Pa, the temperature is 500°C, pretreatment for 3 hours;

[0055] 3) Lower the temperature of the high-temperature furnace to 450° C., let in air, keep the temperature for 5 hours, and then take out the material when the temperature is lowered to room temperature.

[0056] 4) Add 5 grams of sucrose to the mixed powder obtained in step 3), ball mill for 2 hours, put the material back into the high-temperature furnace, and perform high-temperature treatment under an argon atmosphere with a pressure of 1.5×10 5 Pa, the temperature is 650...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com