Method for preparing magnesium lithium alloy cerium salt and molybdate-phosphate-zirconium fluoride conversion coating

A magnesium-lithium alloy and zirconium fluoride technology, which is applied in the coating process of metal materials, can solve the problems of fast solution consumption, unevenness, thin film layer, etc., and achieve good anti-corrosion effect, good bonding and uniform film layer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples describe the present invention in more detail:

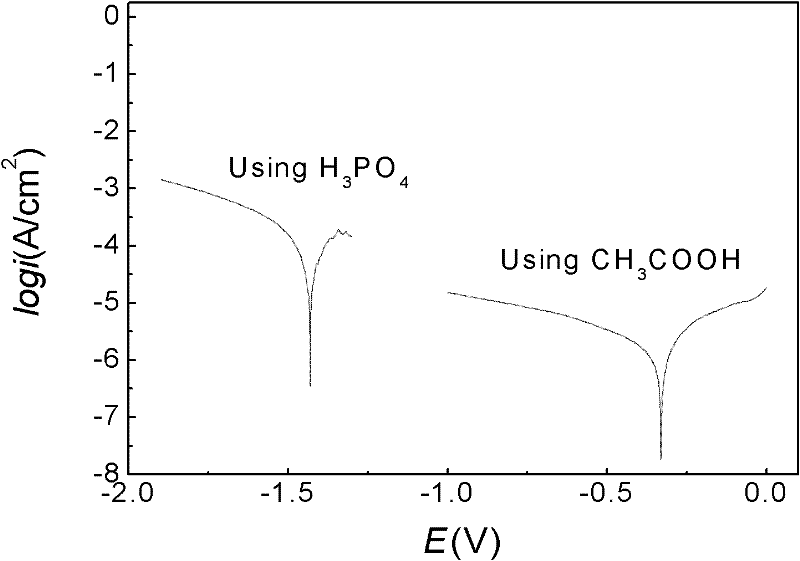

[0030] After degreasing, pickling, and activation, the magnesium-lithium alloy undergoes cerium salt conversion, and a layer of rare earth conversion film is first formed on the surface of the magnesium-lithium alloy. The process condition of cerium salt conversion is:

[0031] The preparation method of cerium salt conversion solution is as follows:

[0032] (1) weigh 8g / L cerium nitrate, dissolve;

[0033] (2) weigh 10g / L citric acid, dissolve;

[0034] (3) weigh 2g / L sodium lauryl sulfate, dissolve;

[0035] (4) weigh 0.2g / L thiourea, dissolve;

[0036] (5) weigh 0.05g / L sodium fluoride, dissolve;

[0037] (6) Weigh 10mL / L of hydrogen peroxide;

[0038] (7) Add solutions (2) and (3) to solution (1) under stirring conditions;

[0039] (8) under stirring conditions, adding solutions (4), (5) to the solution formed in step (7);

[0040] (9) Add solution (6) to the solution formed in step (8) ...

PUM

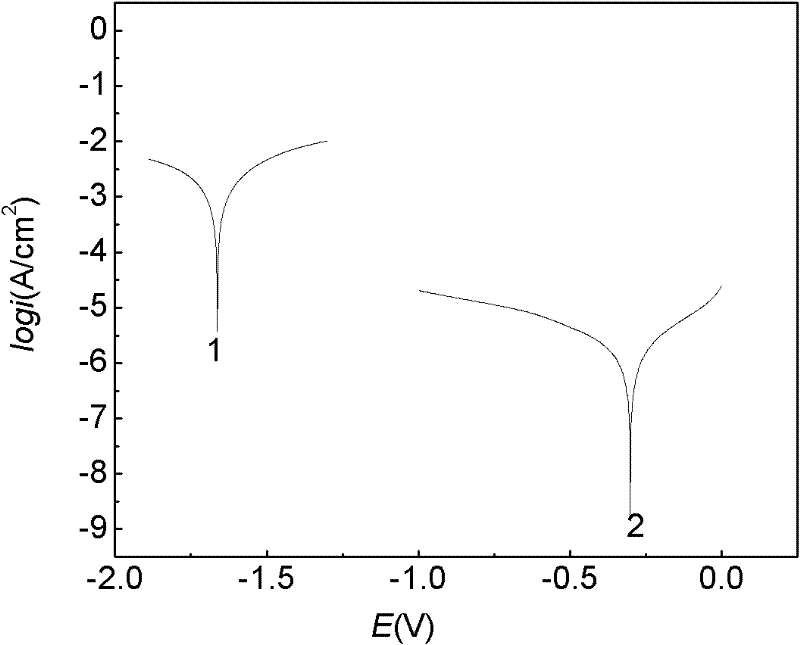

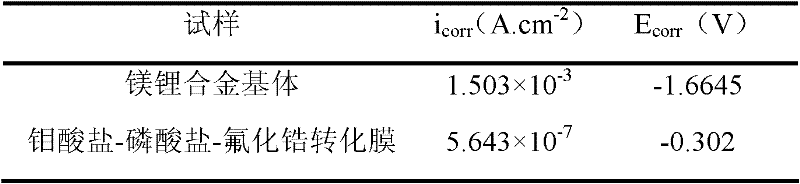

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com