Method for preparing two-stage micron-submicron microstructure on surface of titanium alloy dental implant

A technology of dental implants and titanium alloys, used in implants, dentistry, prosthetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

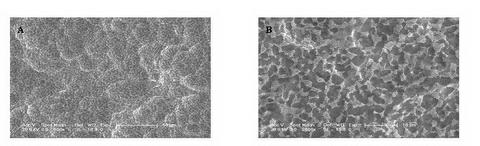

[0022] (1) After the surface of the titanium alloy dental implant is activated (in hydrofluoric acid 29g / L and nitric acid 334g / L), the surface forms a uniform and regular micro-rough surface; Sonicated in deionized water, dried; see figure 1 , image A is ×500, and image B is ×2000.

[0023] (2) Electrode settings: the anode is a titanium alloy dental implant, and the cathode is a platinum sheet;

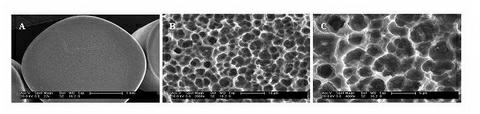

[0024] (3) Put the activated titanium alloy dental implant in the electrolyte (HCl 99g / L, HF 51g / L, NH 4 F 15g / L) for electrolytic etching treatment; treatment parameters: solution temperature 20°C, treatment time 1min, current density 300mA / cm 2 ; ultrasonically cleaned, dried; see figure 2 , Image A is ×27, Image B is ×2000, and Image C is ×4000.

[0025] (4) Place the micron-sized titanium alloy dental implant in HNO 3 (246g / L) for AC corrosion treatment, the treatment parameters are: voltage 4V, etching time 30s; acetone, 95% ethanol, deionized water ultrasonic cleaning, ...

Embodiment 2

[0027] (1) After the surface of the titanium alloy dental implant is activated (in hydrofluoric acid 29g / L and nitric acid 334g / L), the surface forms a uniform and regular micro-rough surface; Ultrasonic cleaning in deionized water, drying;

[0028] (2) Electrode settings: the anode is a titanium alloy dental implant, and the cathode is a platinum sheet;

[0029] (3) Put the activated titanium alloy dental implant in the electrolyte (HCl 108g / L, HF 61g / L, NH 4 F20g / L) for electrolytic etching treatment; processing parameters: solution temperature 22 ℃, processing time 1.5min, current density 250mA / cm 2 ; Ultrasonic cleaning, drying;

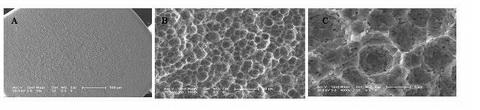

[0030] (4) Place the micron-sized titanium alloy dental implant in HNO 3 (220g / L) for AC corrosion treatment, the treatment parameters are: voltage 6V, etching time 20s; ultrasonic cleaning, drying; surface formation with micron-submicron microstructure, micron-level structure diameter is 2-5μm; sub-micron level 0.1-0.7 μm in diameter; see ...

Embodiment 3

[0032] (1) After the surface of the titanium alloy dental implant is activated (in hydrofluoric acid 29g / L and nitric acid 334g / L), the surface forms a uniform and regular micro-rough surface; Ultrasonic cleaning in deionized water, drying;

[0033] (2) Electrode settings: the anode is a titanium alloy dental implant, and the cathode is a platinum sheet;

[0034] (3) Put the activated titanium alloy dental implant in the electrolyte (HCl 109g / L, HF 60g / L, NH 4 F 25g / L) for electrolytic etching; processing parameters: solution temperature 18°C, processing time 1min, current density 80mA / cm 2 ; Ultrasonic cleaning, drying;

[0035] (4) Place the micron-sized titanium alloy dental implant in HNO 3 (270g / L) for AC corrosion treatment, the treatment parameters are: voltage 2V, etching time 30s; ultrasonic cleaning, drying; so that the surface of the test piece forms a micro-submicron microstructure, and the diameter of the micron-scale structure is 2-5μm; Submicron 0.1-0.7 μm i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com