Aspirin solid dispersion, as well as preparation method, pharmaceutical composition and use thereof

A technology of solid dispersion and aspirin, applied in the field of medicine, can solve the problems of increased incidence of toxic and side effects, reduced drug efficacy, long time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

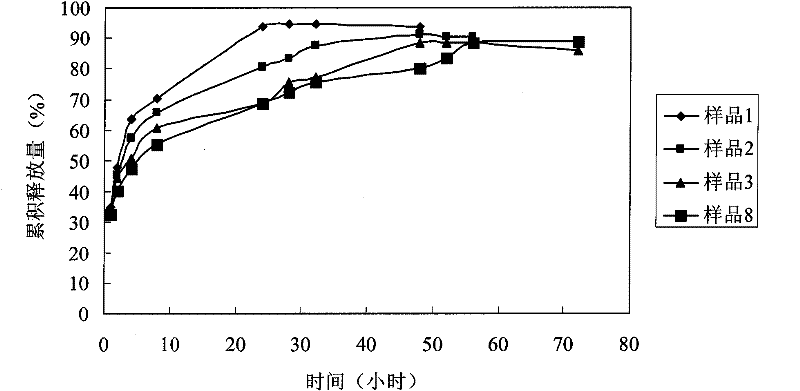

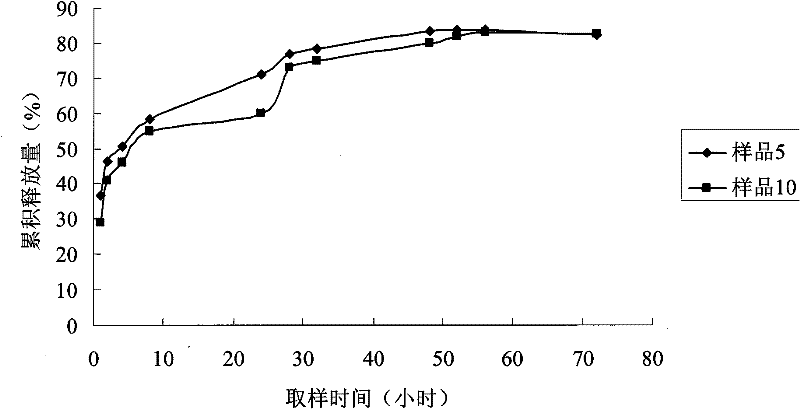

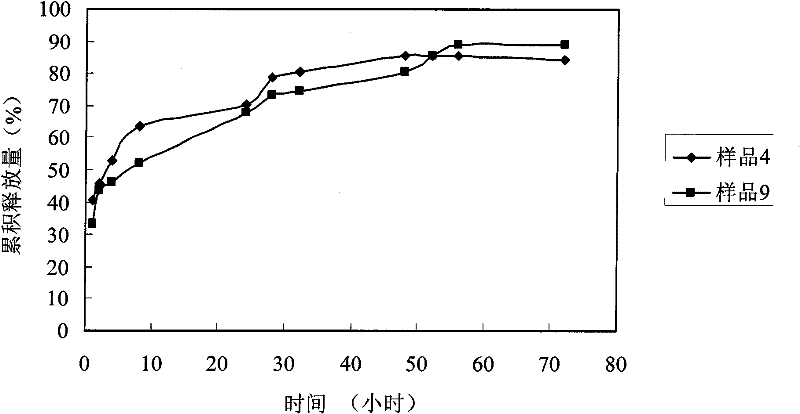

Image

Examples

Embodiment 1

[0079] Feeding amount:

[0080] Aspirin 0.15g

[0081] mPEG-PLA (Mw=2000 / 20000) 3.0g

[0082] Chloroform 30ml

[0083] Preparation method: Take mPEG-PLA, add chloroform, dissolve it by ultrasonication, add aspirin, dissolve it by ultrasonication, and spray dry. The air volume of the ring fan in the spray drying process is 90%, the nitrogen flow rate is 4L / min, the air inlet temperature is 35°C, and the peristaltic pump is used. Feed rate 20%. After the drying is completed, the solid dispersion is collected to obtain the obtained product.

[0084] Aspirin content: 4.5%.

[0085] In this example, the molecular structural formula of mPEG-PLA is

[0086]

[0087] Among them: m≈45, n≈276.

Embodiment 2

[0089] Feeding amount:

[0090] Aspirin 0.15g

[0091] Allanine derivatives of mPEG-PLA 3.0g

[0092] Chloroform 30ml

[0093] Note: The molecular structural formula of the aminopropionic acid derivative of mPEG-PLA is

[0094]

[0095] Where: m≈45, n≈276, R=-COCH 2 CH 2 NH 2

[0096] Preparation method: Take the aminopropionic acid derivative of mPEG-PLA, add chloroform, dissolve by ultrasonication, add aspirin, dissolve by ultrasonication, and spray dry. The air volume of the ring fan is 90%, the nitrogen flow rate is 4L / min, and the air inlet temperature is 35°C. Peristaltic pump feed rate 20%. After the drying is completed, the solid dispersion is collected to obtain the obtained product.

[0097] Aspirin content: 4.7%.

Embodiment 3

[0099] Feeding amount:

[0100] Aspirin 0.5g

[0101] mPEG-PLA (Mw=2000 / 80000) 5.0g

[0102] Cholesterol 0.25g

[0103] Dichloromethane 35ml

[0104] Preparation method: Take mPEG-PLA, add dichloromethane, dissolve it by ultrasonication, add cholesterol and aspirin in turn, dissolve it by ultrasonication, and spray dry. Pump feed rate 10%. After the drying is completed, the solid dispersion is collected to obtain the obtained product.

[0105] Aspirin content: 8.3%.

[0106] In this example, the molecular structural formula of mPEG-PLA is

[0107]

[0108] Among them: m≈45, n≈1104.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com