Ferromagnetic Co3C@C core-shell nanostructure and continuous preparation method thereof

A nanostructure, ferromagnetic technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of many by-products, long time-consuming, complicated operation process, etc., and achieve the effect of strong ferromagnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

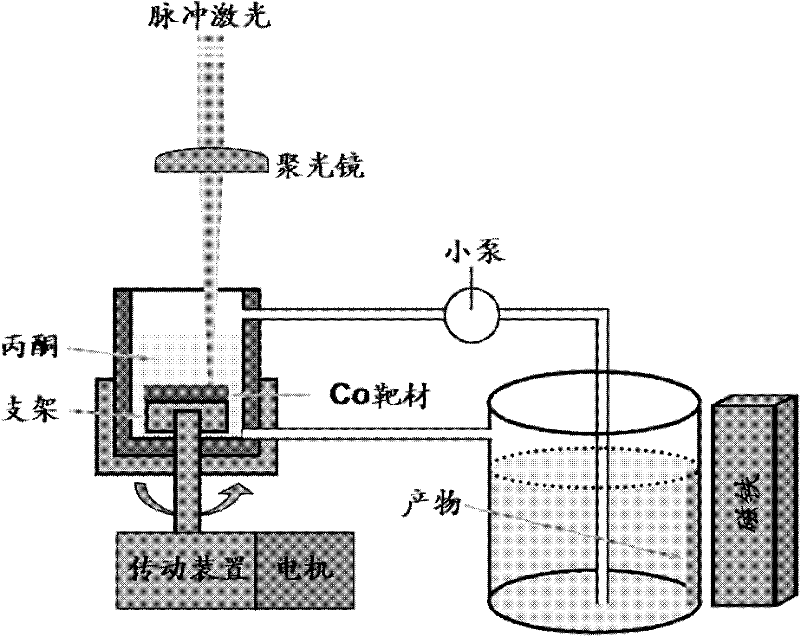

[0023] Example 1: Ferromagnetic Co 3 A continuous preparation method for CC core-shell nanostructures, comprising the following steps:

[0024] Polish the surface of the Co simple target material with fine sandpaper first, put it into ethanol and acetone solutions for ultrasonic cleaning for 10 minutes each, and then fix it on the support of the rotary table, slowly inject acetone liquid and keep the liquid phase laser ablation cavity. Acetone liquid is 20ml, Nd:YAG pulse laser is used, the wavelength is 1064nm, the energy is 100mJ, ablation of Co single substance target for 5-8h, to obtain Co 3 CC core-shell nanostructures.

Embodiment 2

[0025] Example 2: Co 3 Schematic diagram of the continuous preparation principle of CC core-shell nanostructures, such as figure 1 As shown, the surface of the metal Co target is first polished with fine sandpaper, put into ethanol and acetone solutions for ultrasonic cleaning for 10 minutes each, and then fixed on the support of the rotary table, start the small pump and slowly inject the acetone liquid and maintain the liquid phase The acetone liquid in the laser ablation cavity is 20ml, using a Nd:YAG solid-state laser with a pulse of 10ns, a wavelength of 1064nm, and an energy of 100mJ, through a focusing lens to vertically incident on the surface of the Co target, so that the diameter of the focused spot is 1mm, and the The rotary table rotates continuously to perform continuous liquid-phase laser ablation. When the acetone solution flows into the large container, the product with strong ferromagnetism is adsorbed on the wall of the container by the magnet. The acetone so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com