Organic porous gel absorbent, preparation method and application thereof

An adsorbent and organic technology, applied in the field of organic porous gel adsorbent and its preparation, can solve the problems of long adsorption time of activated carbon, high post-treatment cost, limited application, etc., and achieve easy mass industrial production, easy recovery, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, preparation organic porous gel adsorbent

[0029] The preparation of the organic porous gel adsorbent in this embodiment comprises the following steps:

[0030] (a) get phthaloyl chloride, L-phenylalanine methyl ester hydrochloride, triethylamine; the mol ratio of said phthaloyl chloride, L-phenylalanine methyl ester hydrochloride, triethylamine 1:2:6; the raw materials can be obtained from open commercial channels;

[0031] (b) Cool the anhydrous dichloromethane solution of L-phenylalanine methyl ester hydrochloride to 0°C, add triethylamine, and then add the anhydrous dichloromethane solution of terephthaloyl chloride to obtain a reaction solution ; The reaction solution was slowly raised to room temperature and stirred for 12 to 16 hours;

[0032] (c) Rotate the reaction solution, add deionized water, collect the precipitate by filtration, recrystallize the obtained precipitate with ethanol, filter and dry in an oven for 10 to 12 hours at a drying t...

Embodiment 2

[0035] Embodiment 2, the use of organic porous gel adsorbent

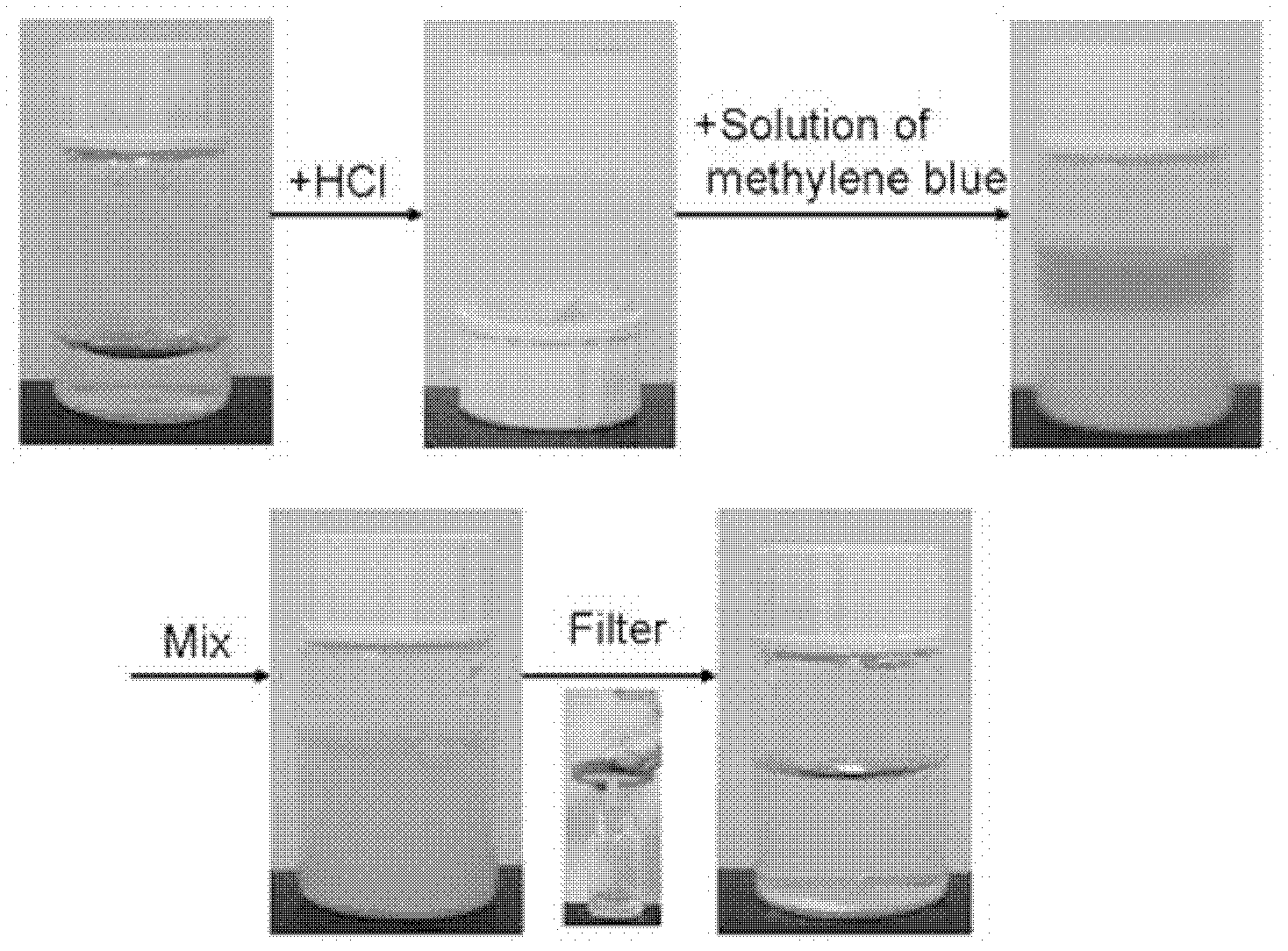

[0036] 2.1 Adsorption of methylene blue

[0037] First, dissolve 36.6mg of gel adsorbent powder in 1ml of sodium hydroxide solution (2M), then add 10ml of hydrochloric acid solution (0.3M) to make 11ml of hydrogel (3.33mg / ml), add 4ml of The methylene blue solution (0.1 mg / ml) was mixed evenly and then filtered with a needle filter. After the treatment, the adsorption rate of the adsorbent to methylene blue was as high as 97.61%. Adsorption process see image 3 : After the dry gel was dissolved with sodium hydroxide solution, hydrogel was acidified by adding hydrochloric acid; methylene blue was added to the hydrogel and mixed evenly with the gel; the mixed solution of hydrogel and dye was filtered with a needle filter; Test the ultraviolet-visible spectrogram (see Figure 4 The characteristic absorption peak intensity of methylene blue in the filtrate after hydrogel treatment is 0.0537, and the characteristic...

Embodiment 3

[0042] Embodiment 3, recycling of organic porous gel adsorbent

[0043] Dissolve 500 mg of methylene blue adsorbent in 5 ml of sodium hydroxide solution, then add 35 ml of chloroform for extraction, take the upper aqueous solution, add hydrochloric acid solution to acidify it into a gel, filter, and dry. The recovery rate can reach 90%. see recycling process Figure 9 : After 500mg of dye adsorbent is used to adsorb methylene blue dye, after dissolving with sodium hydroxide, extracting with chloroform, acidifying with hydrochloric acid, filtering and drying, the recovered quality by weighing is 450mg, and the recovery rate is 90%.

[0044] In summary, the organic porous gel adsorbent of the present invention is a low molecular weight gel adsorbent with activated carbon porous structure; the organic gel adsorbent can quickly and efficiently capture the dyes, and the adsorbent is easy to recover and low in cost. The dye adsorption process is carried out at room temperature, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com