Preparation method for silver and stannic oxide composite powder and application thereof

A technology of silver tin oxide and composite powder, which is applied to contacts, electrical components, circuits, etc., and can solve problems such as failure to meet environmental protection requirements, complicated production process, and large investment in equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

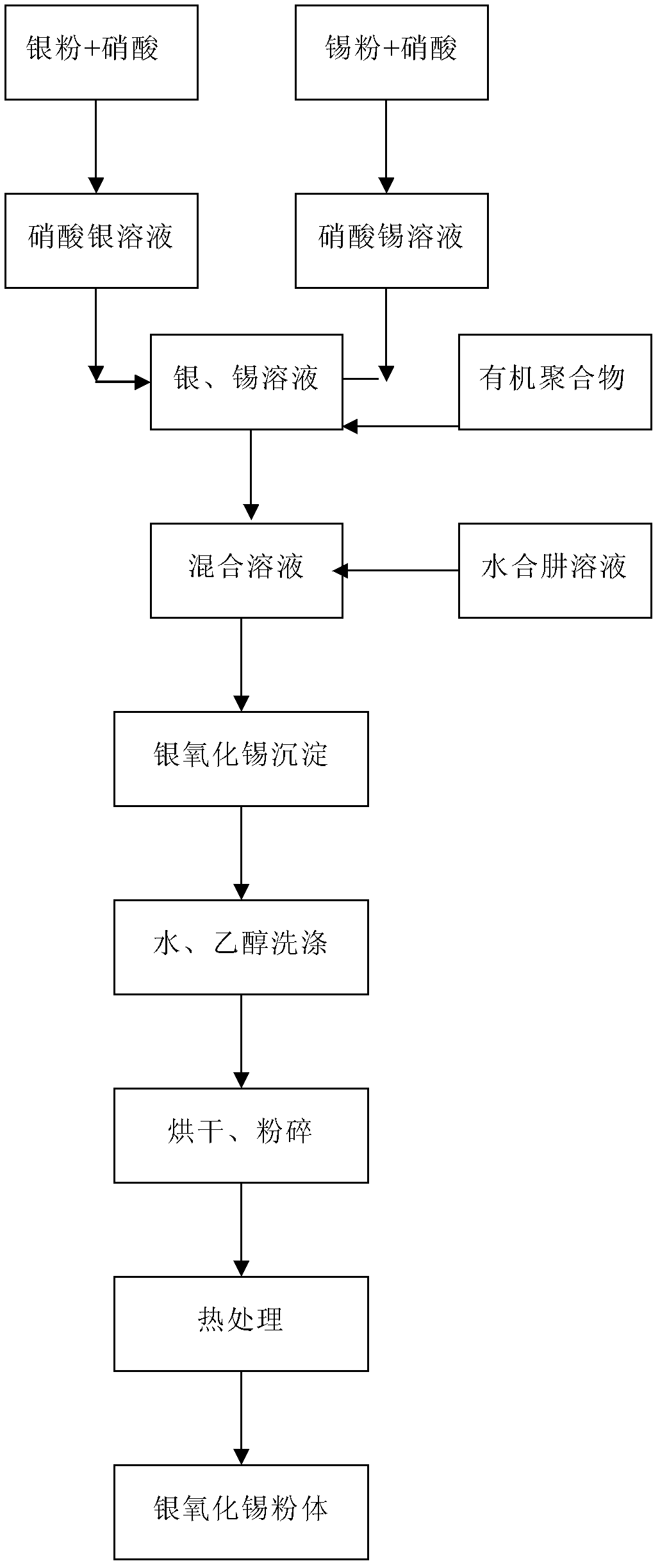

[0052] After extensive and in-depth research, the present inventor has established a preparation method of silver tin oxide composite powder. Specifically, the method includes the steps of: respectively dissolving metallic silver and metallic tin in nitric acid solution to obtain a silver nitrate solution and a tin nitrate solution; mixing the silver nitrate solution and the tin nitrate solution with an organic polymer, and performing a precipitation reduction reaction, Obtaining a solution containing a suspension of silver tin oxide; filtering the solution containing a suspension of silver tin oxide, washing, drying, and pulverizing the silver tin oxide mixture to obtain a powder with a particle size of less than 10 μm; heat-treating the obtained powder, Obtain silver tin oxide composite powder. The particle size of the silver-tin oxide composite powder prepared by the method is less than 10 μm, and the silver-tin oxide composite powder has the characteristics of high element...

Embodiment 1

[0079] Dissolve metallic silver in nitric acid with a concentration of 0.2mol / L to form a silver nitrate solution at a temperature of 0°C, and dissolve metal tin powder in nitric acid with a concentration of 0.15mol / L to form a tin nitrate solution at a temperature of 0°C. for an ice water bath.

[0080] Mix the above silver nitrate solution and tin nitrate solution, and add polyvinyl alcohol to it at the same time, wherein the mass of polyvinyl alcohol is 2% of the mass of the silver tin oxide powder, and the high molecular weight substance is added at a temperature of 5°C. The ratio between silver and tin is 75:25 for the mass ratio of silver to the mass of tin added after it is completely converted into tin oxide.

[0081] Hydrazine hydrate with a concentration of 0.3 mol / L was added dropwise to the above solution to carry out precipitation reduction reaction, and the temperature during the reaction was controlled at 10°C to obtain a silver gray suspension. Use plate and f...

Embodiment 2

[0083] Dissolve metallic silver in nitric acid with a concentration of 2.0mol / L to form a silver nitrate solution at a dissolution temperature of 30°C, and dissolve metal tin powder in nitric acid with a concentration of 3.0mol / L to form a tin nitrate solution at a dissolution temperature of 0°C. for an ice water bath. The above-mentioned silver nitrate solution and tin nitrate solution are mixed, and polyethylene glycol is added thereto at the same time, wherein the quality of polyethylene glycol is 12% of the mass of silver tin oxide powder obtained according to theory, and the high molecular weight substance is added at a temperature of 25 ℃. The ratio between silver and tin is 85:15 for the mass ratio of silver to the mass of tin added after it is completely converted into tin oxide. Hydrazine hydrate with a concentration of 3.0 mol / L was added dropwise to the above solution to carry out precipitation reduction reaction, and the temperature during the reaction was control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com