Method for preparing aluminum oxide nano bars

A technology of alumina nano and aluminum nitrate, applied in the direction of alumina/aluminum hydroxide, nanotechnology, etc., can solve the problems of complex process, low output, and difficulty in industrialization, and achieve good dispersion, low cost, and good shape controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

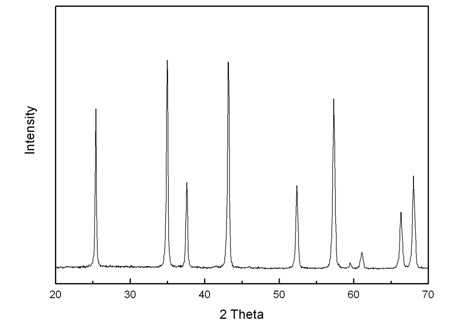

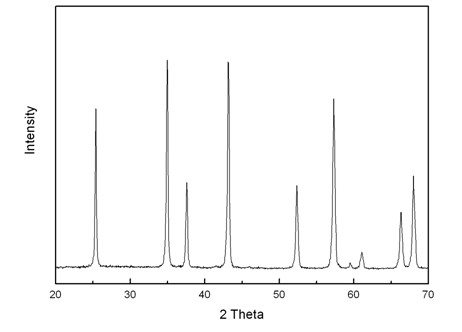

[0016] Weigh 20g (0.1mol) of aluminum nitrate nonahydrate, 4.8g (0.15mol) of urea, 2.6g of starch, 1g of sodium chloride, and add 1ml of deionized water to grind into a colloid; ignite the resulting colloid at 450°C to obtain a gray-black precursor Then the precursor was ground until dispersed; the ground precursor was annealed at 1080°C for 0.5 hours, washed, and dried at 150°C for 2 hours to obtain alumina nanorods. The prepared aluminum oxide nanorods are single crystals with a diameter of 15nm-25nm, a length of 80nm-140nm, and an aspect ratio of 5-8.

Embodiment 2

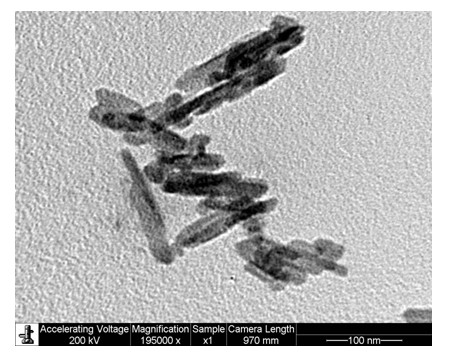

[0018] Weigh 20g (0.1mol) aluminum nitrate nonahydrate, 6.4g (0.2mol) urea, 3g starch, 1.5g sodium chloride and sodium nitrate (mass ratio 1:1), add 1.5ml deionized water and grind into a colloid; The obtained colloid was ignited at 400°C to obtain a gray-black precursor, which was then ground until dispersed; the ground precursor was annealed at 1080°C for 0.5 hours, washed, and dried at 100°C for 2 hours to obtain alumina nanorods. like figure 2 As shown, the prepared alumina nanorods are single crystals with a diameter of 15nm-25nm, a length of 80nm-140nm, and an aspect ratio of 5-8.

Embodiment 3

[0020] Weigh 20g (0.1mol) of aluminum nitrate nonahydrate, 6.4g (0.2mol) of urea, 3.5g of cellulose, 1g of sodium nitrate, and add 1ml of deionized water to grind into a colloid; ignite the resulting colloid at 400°C to obtain a gray-black precursor Then the precursor was ground until dispersed; the ground precursor was annealed at 1080°C for 0.5 hours, washed, and dried at 200°C for 2 hours to obtain alumina nanorods. The prepared aluminum oxide nanorods are single crystals with a diameter of 15nm-25nm, a length of 80nm-140nm, and an aspect ratio of 5-8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com