Corrosion inhibitor for boiler acid washing and production method thereof

A boiler acid and corrosion inhibitor technology, applied in chemical instruments and methods, complex/solubilizer treatment, water/sludge/sewage treatment, etc., can solve problems such as strong irritating odor, short shelf life, and unstable performance. , to achieve the effect of stable chemical properties, low toxicity and strong scale-dissolving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

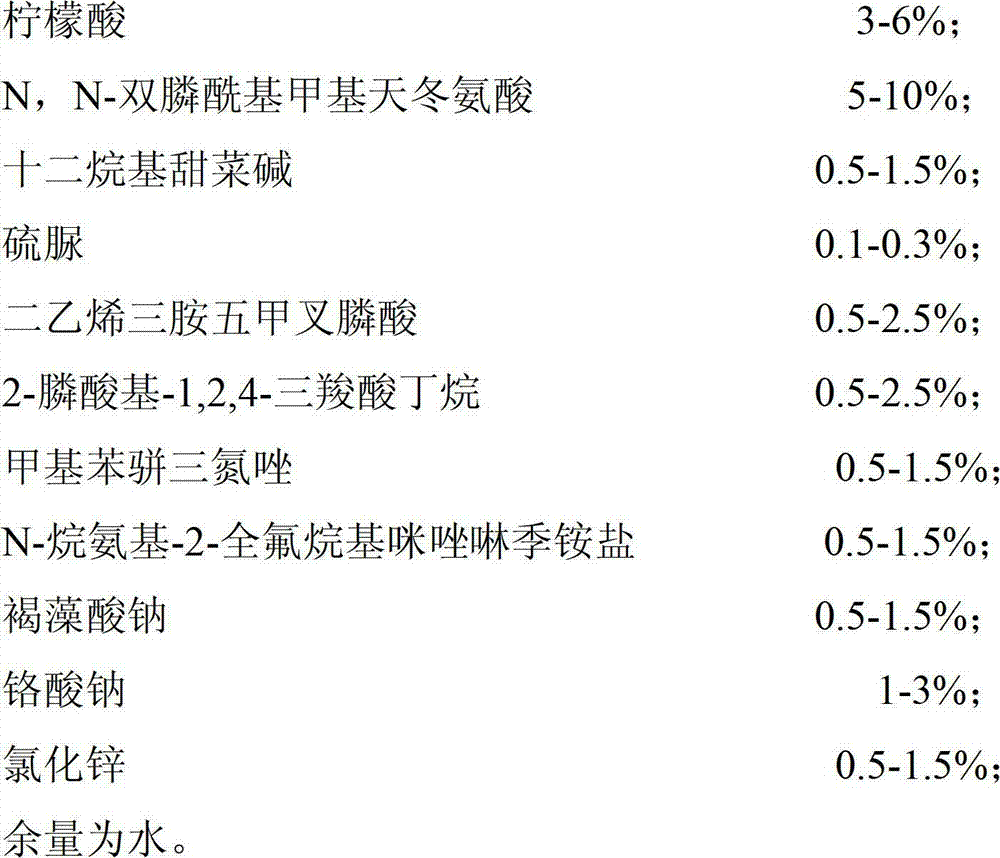

[0029] Raw material preparation:

[0030] Weigh 100 kilograms of raw materials, of which:

[0031] 3 kg of citric acid;

[0032] N, N-bisphosphonomethyl aspartic acid 10 kg;

[0033] Lauryl betaine 0.5 kg;

[0034] Thiourea 0.3 kg;

[0035] 0.5 kg of diethylenetriaminepentamethylenephosphonic acid;

[0036] 2.5 kg of 2-phosphono-1,2,4-tricarboxylic butane;

[0037] Tolyltriazole 0.5 kg;

[0038] 1.5 kg of N-alkylamino-2-perfluoroalkyl imidazoline quaternary ammonium salt;

[0039] Sodium alginate 0.5 kg;

[0040] Sodium chromate 3 kg;

[0042] The balance is water.

[0043] That is, water and dialkyl betaine, thiourea, diethylenetriaminepentamethylenephosphonic acid, 2-phosphono-1,2,4-tricarboxylic butane, methylbenzotriazole, N- The total weight of alkylamino-2-perfluoroalkyl imidazoline quaternary ammonium salt, sodium alginate, sodium chromate, zinc chloride, citric acid and N,N-bisphosphonomethylaspartic acid is 100 kg.

[0044] H...

Embodiment 2

[0051] Raw material preparation:

[0052] Weigh 100 kilograms of raw materials, of which:

[0053]6 kg of citric acid;

[0054] N, N-bisphosphonomethyl aspartic acid 5 kg;

[0055] Lauryl betaine 1.5 kg;

[0056] Thiourea 0.1 kg;

[0057] 2.5 kg of diethylenetriaminepentamethylenephosphonic acid;

[0058] 2-phosphono-1,2,4-tricarboxylic acid butane 0.5 kg;

[0059] Tolyltriazole 1.5 kg;

[0060] 0.5 kg of N-alkylamino-2-perfluoroalkyl imidazoline quaternary ammonium salt;

[0061] Sodium alginate 1.5 kg;

[0062] Sodium chromate 1 kg;

[0063] Zinc chloride 1.5 kg.

[0064] The balance is water.

[0065] That is, water and dialkyl betaine, thiourea, diethylenetriaminepentamethylenephosphonic acid, 2-phosphono-1,2,4-tricarboxylic butane, methylbenzotriazole, N- The total weight of alkylamino-2-perfluoroalkyl imidazoline quaternary ammonium salt, sodium alginate, sodium chromate, zinc chloride, citric acid and N,N-bisphosphonomethylaspartic acid is 100 kg.

[0066] H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com