Lubricating oil composition and preparation method thereof

A lubricating oil composition and lubricating oil technology, applied in the direction of lubricating compositions, petroleum industry, additives, etc., can solve the problems of additive function loss, incompatible lubricating oil, desorption of surfactants, etc., to reduce wear resistance, reduce The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

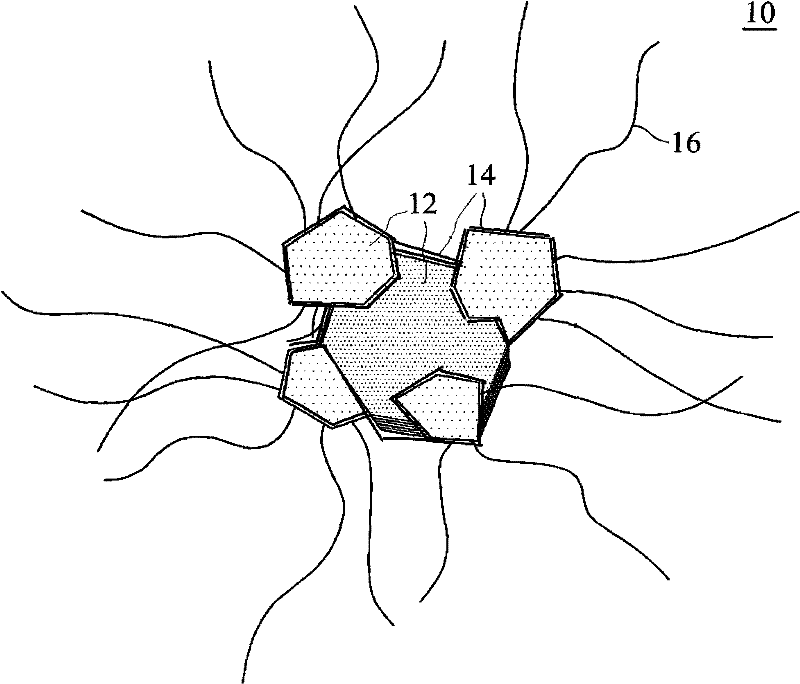

[0028] The preparation method of the organic / inorganic nanocomposite particles includes the following steps: firstly, mixing a nanodiamond particle (for example, ultra-dispersed nanodiamond) with a reactive monomer to obtain a mixture, wherein the reactive monomer will be synthesized in a subsequent polymerization process Forming polymer chains grafted on the nano-diamond particles, for example: methyl methacrylate, glycidyl methacrylate, styrene, or a mixture thereof. The above mixture may further include a solvent, which may be a general polar solvent such as ethanol or acetone, or a non-polar solvent such as toluene, depending on the polarity of the grafted monomer. Then, the solution is subjected to a wet ball milling disaggregation process, and a free radical initiator is added during the ball milling process to perform a polymerization reaction on the reactive monomer. In other words, the feature of the present invention is to deagglomerate nano-diamond particles (such a...

Embodiment 1

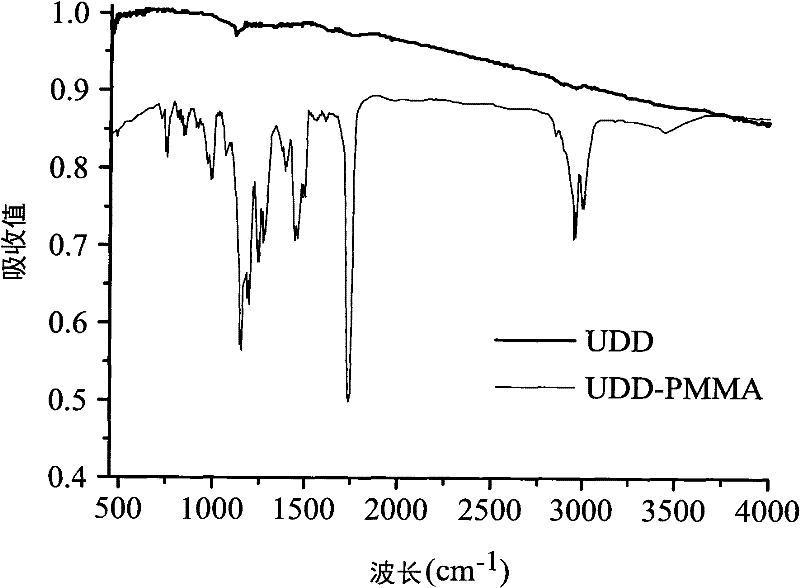

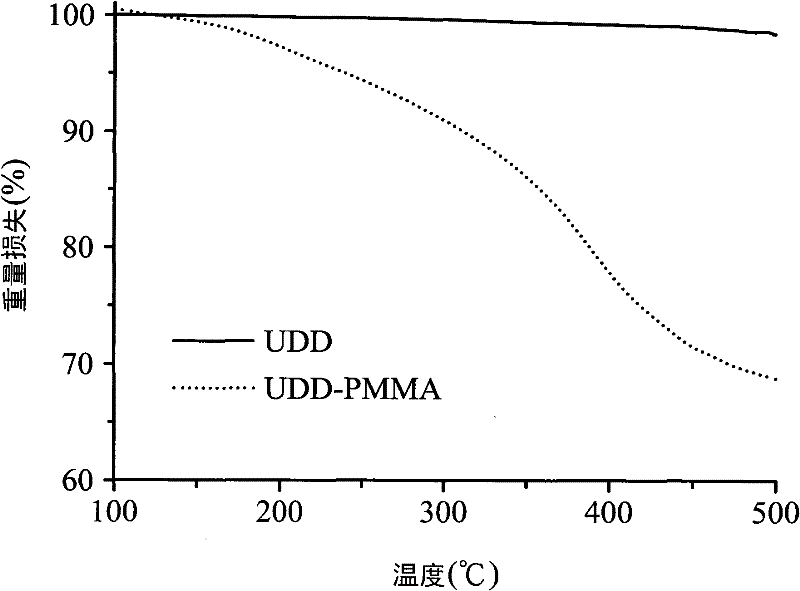

[0034] Mix 400 grams of zirconia balls (particle size about 50 μm) and 10 grams of ultra-dispersed nano-diamonds (the product number is UDD, purchased from ABBA group of Bohan Enterprise Co., Ltd., prepared in a closed explosion method and pickling to remove impurities. ), and add 80g of methyl methacrylate monomer, and the resulting mixture is placed in a ball mill cavity groove. The temperature of the external circulating water in the ball mill chamber is set at 80°C, and the ball mill speed is set at 2400 revolutions per minute. Finally, 10 grams of free radical initiator benzoyl peroxide (benzoyl peroxide) was dissolved in 10 milliliters of toluene, and injected into the cavity at a flow rate of about 5 milliliters per hour during the ball milling process. The agglomerated nano-diamonds are dispersed by ball milling, and at the same time, the free radicals of the monomer polymerization reaction produced by benzene peroxide are added on the surface of the nano-diamonds, so ...

Embodiment 2

[0037] Examples 2 and 3 were carried out in the same manner as in Example 1, but glycidyl methacrylate and styrene-substituted methyl methacrylate were used as reactive monomers. Please refer to Figure 4 , which is the infrared absorption spectrum of the nano-diamond-grafted polyglycidyl methacrylate (UDD-PGMA) obtained in Example 2 and the nano-diamond-grafted polystyrene (UDD-PS) obtained in Example 3. and Figure 6 The nano-diamond grafted polyglycidyl methacrylate (UDD-PGMA) obtained in Example 2 was analyzed by particle size, and the result showed that the average particle size (d50) was about 10 nm. and Figure 7 The nano-diamond-bonded polystyrene (UDD-PS) obtained in Example 3 was analyzed by particle size, and the result showed that the average particle size (d50) was about 100 nm.

[0038] Preparation and Property Measurement of Lubricating Oil Composition

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com