Low stress, antiwear and antifriction gradient Ni-Co nanometer alloy plate preparation method

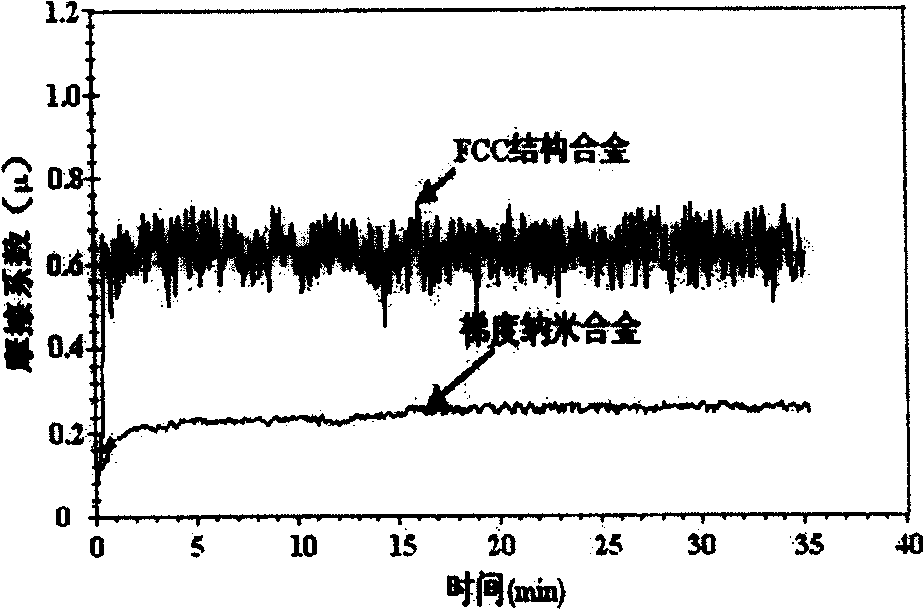

A nano-alloy, low-stress technology, applied in the preparation of anti-wear and anti-friction gradient Ni-Co nano-alloy coatings, low-stress field, can solve the problems of large internal stress and single function of nano-alloy coatings, and achieve high wear resistance, The effect of simple operation and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

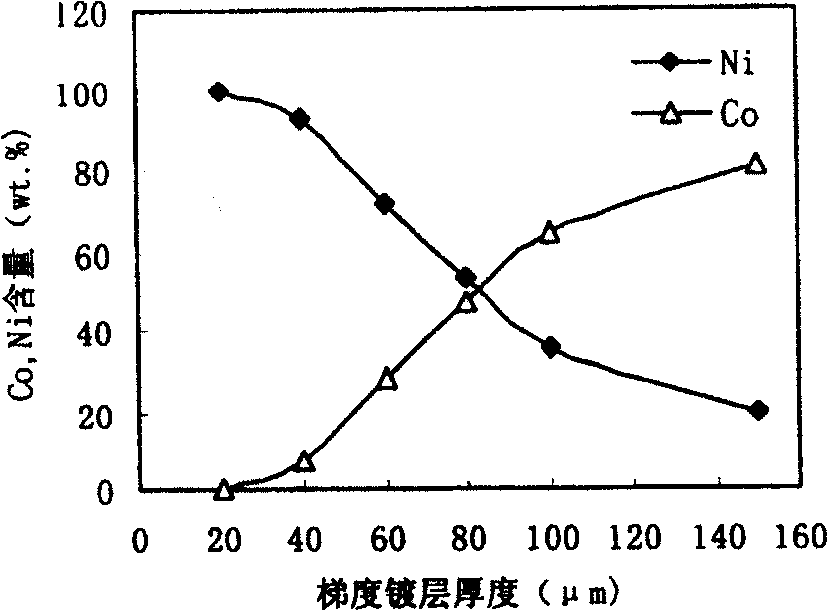

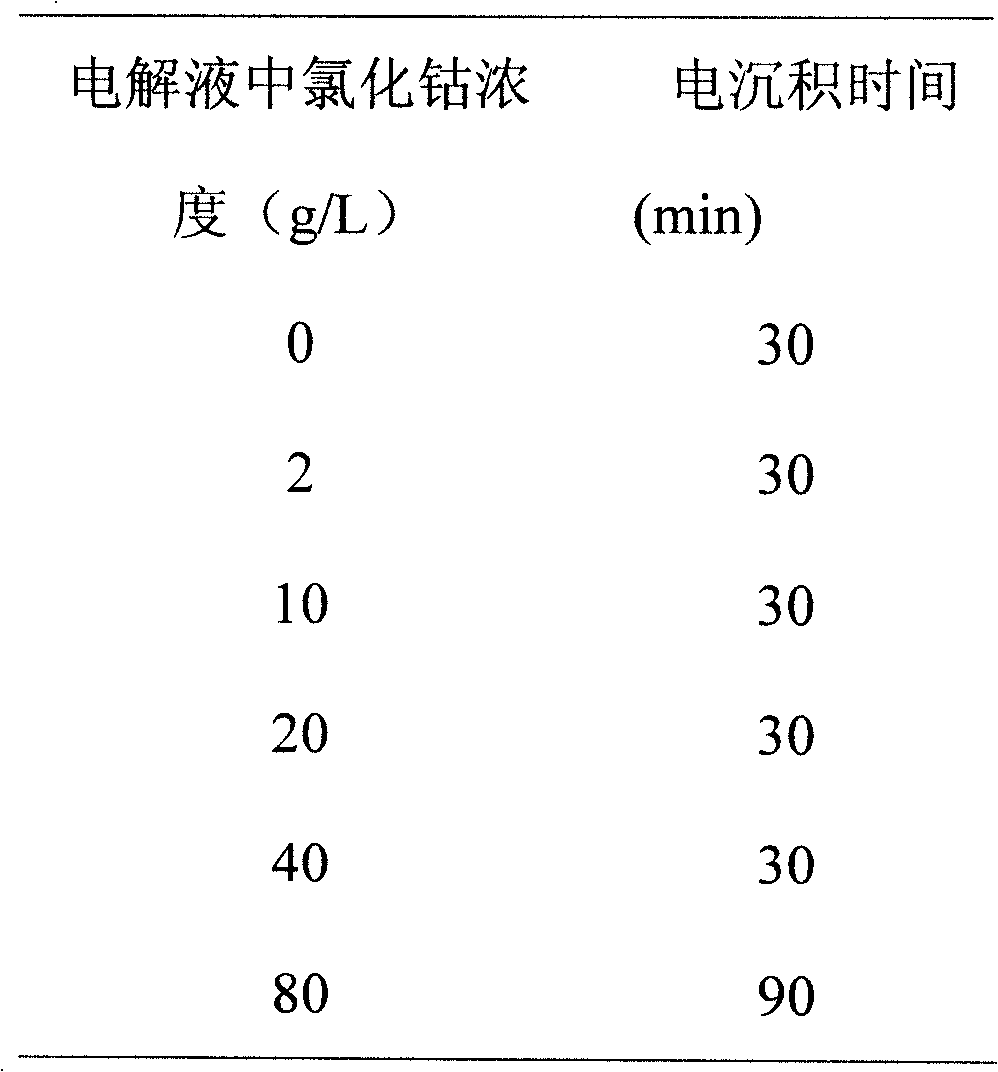

[0019] The pure nickel sheet is used as the anode, and the workpiece to be processed is used as the cathode. The solution composition of electrodeposition gradient Ni-Co nano-alloy coating is as follows: every liter of electrolyte contains 200 grams of nickel sulfate, 20 grams of sodium chloride, 30 grams of boric acid, 0-80 grams of cobalt chloride and 1-4 grams of sodium saccharinate . Maintain the plating temperature at 40-45°C, the pH value of the plating solution is 3-4.5, and the current density is 3-5A / dm 2 . The steel and copper metal workpieces after conventional chemical degreasing and acid activation are electro-deposited according to the above-mentioned plating solution composition and process conditions. During the deposition process, the cobalt salt concentration is gradually increased and the corresponding deposition is controlled according to the process shown in Table 1. time (see Table 1), a gradient Ni-Co nano-alloy coating with a thickness greater than 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com