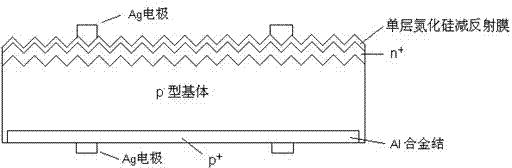

Preparation process for gradient antireflection silicon nitride thin film of crystalline silicon solar cell

A silicon nitride thin film and solar cell technology, applied in the field of solar cells, can solve problems such as lower conversion efficiency, lower output current, and light absorption loss, and achieve the effects of increased conversion efficiency, reduced reflection, and improved anti-reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

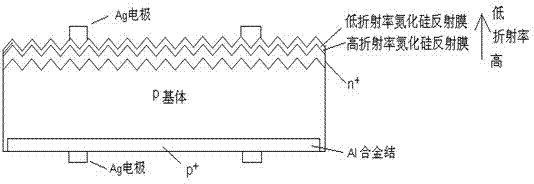

Embodiment 1

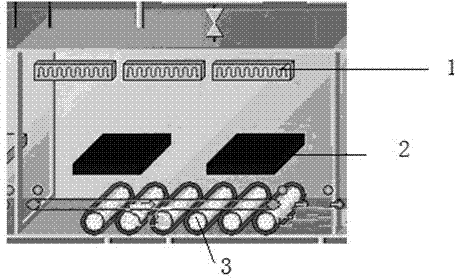

[0030] The preparation process of the gradient anti-reflection silicon nitride thin film of the crystalline silicon solar cell provided in this embodiment is as follows : Using a P-type substrate, the formation of n by phosphorus diffusion + Diffusion layer, using Roth&Rau board P 3200+ equipment (partial structure of which is as image 3 As shown in , the same below) PECVD process is used to set the power to 3500W, the temperature to 450°C, and the air pressure to 226Pa. The flow ratio of ammonia gas is 1:4, the flow ratio of silane and ammonia gas in the fifth and sixth quartz tubes is 1:6, and a layer of gradient silicon nitride anti-reflection coating with a refractive index from high to low is deposited, such as figure 2 As shown, screen-print aluminum paste and silver paste on the back of the silicon wafer, screen-print silver paste on the front, form metal contacts after sintering, and finally test and sort.

[0031] The graded silicon nitride anti-reflection coating...

Embodiment 2

[0033] The preparation process of the gradient anti-reflection silicon nitride thin film of the crystalline silicon solar cell provided in this embodiment is as follows : Using a P-type substrate, the formation of n by phosphorus diffusion + Diffusion layer, using Roth&Rau plate P 3200+ equipment, using PECVD process to set the temperature at 430°C, the air pressure at 239Pa, the power of the first quartz tube is 2900W, the flow ratio of silane and ammonia is 1:2, and the power of the second quartz tube is 2900W , The flow ratio of silane and ammonia is 1:3, the power of the third quartz tube is 3000W, the flow ratio of silane and ammonia is 1:4, the power of the fourth quartz tube is 3000W, and the flow ratio of silane and ammonia is 1: 5. The power of the fifth quartz tube is 3100W, the flow ratio of silane and ammonia is 1:6, the power of the sixth quartz tube is 3100W, the flow ratio of silane and ammonia is 1:7, deposit a layer of refractive index from high to Low gradie...

Embodiment 3

[0036] The preparation process of the gradient anti-reflection silicon nitride thin film of the crystalline silicon solar cell provided in this embodiment is as follows : Using an N-type substrate, the formation of n by phosphorus diffusion + Diffusion layer, using Roth&Rau plate P 3200+ equipment, using PECVD process to set the temperature at 400°C, the air pressure at 239Pa, the power of the first quartz tube is 2900W, the flow ratio of silane and ammonia is 1:2, and the power of the second quartz tube is 2900W , The flow ratio of silane and ammonia is 1:3, the power of the third quartz tube is 3000W, the flow ratio of silane and ammonia is 1:4, the power of the fourth quartz tube is 3000W, and the flow ratio of silane and ammonia is 1: 5. The power of the fifth quartz tube is 4000W, the flow ratio of silane and ammonia is 1:6, the power of the sixth quartz tube is 4000W, the flow ratio of silane and ammonia is 1:7, deposit a layer of refractive index from high to Low gradi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com