Process for modifying lead tungstate crystal by utilizing diffusion method

An ion diffusion method, lead tungstate technology, applied in crystal growth, diffusion/doping, chemical instruments and methods, etc., can solve the problems of lead tungstate crystal cracking, difficult to obtain high-quality lead tungstate crystals, etc., to achieve Reduce energy consumption and time, improve flicker performance, high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. PbO powder with 99.999% purity and WO with 99.999% purity 3 Powder is the raw material, according to n(PbO):n(WO 3 ) = 1:1 molar ratio precise ingredients, use the crucible drop method to grow lead tungstate crystals [see: Journal of Crystal Growth 2002, 236, 589-595.], orientate, cut and grind into 10mm× 10mm×2mm pure lead tungstate wafer, cleaned to obtain pure lead tungstate crystal samples;

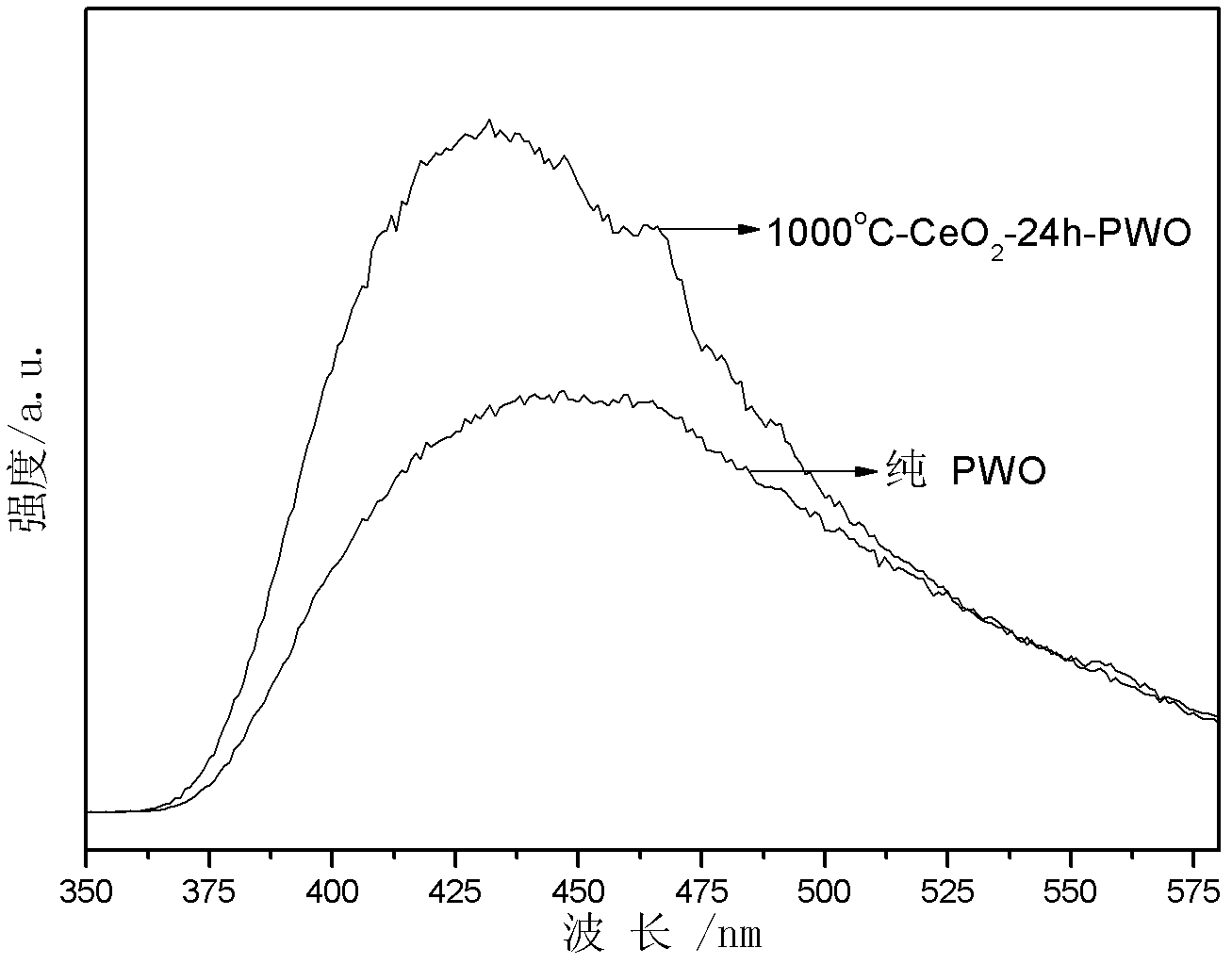

[0027] 2. Put the pure lead tungstate crystal sample obtained in step 1 into a CeO with analytically pure purity. 2In the corundum crucible of powder, the pure lead tungstate crystal sample is tightly wrapped (such as figure 1 shown), then put the crucible into a muffle furnace to heat up at a rate of 15°C / min, the temperature rises to 1000°C, keeps the temperature for 24h, and then cools down to room temperature naturally, and the entire diffusion atmosphere is air;

[0028] 3. After the diffusion is over, the diffused lead tungstate crystal obtained in step 2 is cleaned...

Embodiment 2

[0030] 1, process step is with step 1 in embodiment 1;

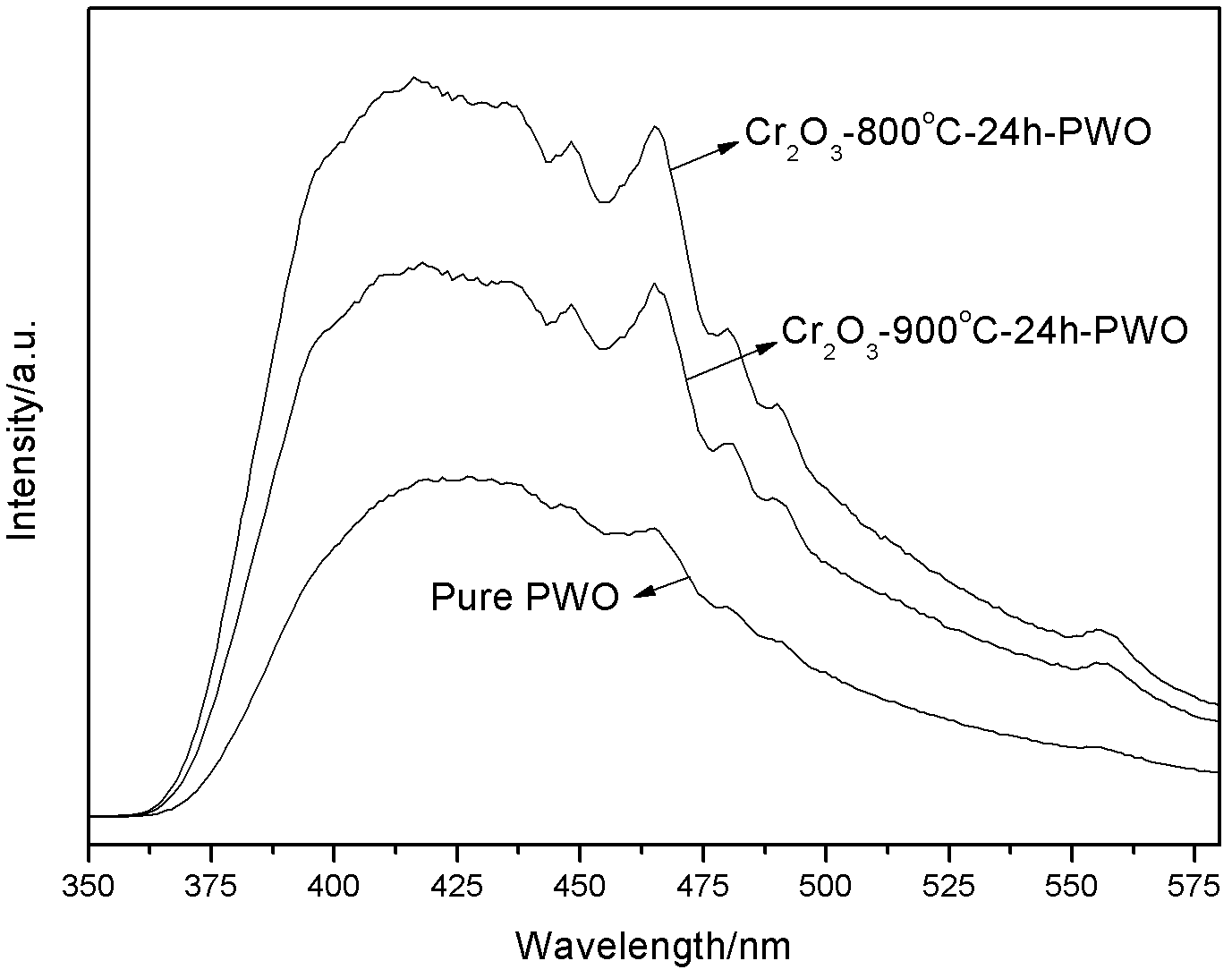

[0031] 2. Put the lead tungstate crystal sample obtained in step 1 into a container with a purity of analytically pure Cr 2 o 3 In the corundum crucible of powder, the lead tungstate wafer is tightly wrapped, and then the crucible is put into the muffle furnace to raise the temperature, the heating rate is 15 ℃ / min, the temperature rises to 900 ℃, and the temperature is kept for 24 hours, and the temperature is naturally cooled to room temperature. The entire diffusion atmosphere is air;

[0032] 3. The process steps are the same as step 3 in Example 1. The fluorescence spectrogram of gained modified lead tungstate crystal sample is shown in image 3 .

Embodiment 3

[0034] 1, process step is with step 1 in embodiment 1;

[0035] 2. Put the pure lead tungstate crystal sample obtained in step 1 into a container with a purity of analytically pure Sm 2 o 3 In a corundum crucible of powder, the pure lead tungstate crystal sample is tightly wrapped, and then the crucible is placed in a muffle furnace to heat up at a heating rate of 15°C / min, the temperature rises to 800°C, and the temperature is kept for 24 hours, and the temperature is naturally cooled to At room temperature, the entire diffusion atmosphere is air;

[0036] 3. The process steps are the same as step 3 in Example 1. The fluorescence spectrogram of gained modified lead tungstate crystal sample is shown in Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com