Integration-type gas controller of dual-purpose fuel tanker and gas jetting time correcting method

A dual-purpose fuel and injection time technology, applied in fuel injection control, electrical control, engine control, etc., can solve problems such as poor vehicle power and comfort, limited electromagnetic compatibility tolerance, engine vibration, etc., to achieve enhanced power performance and comfort, avoid severe jitter, and maintain the effect of air-fuel ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

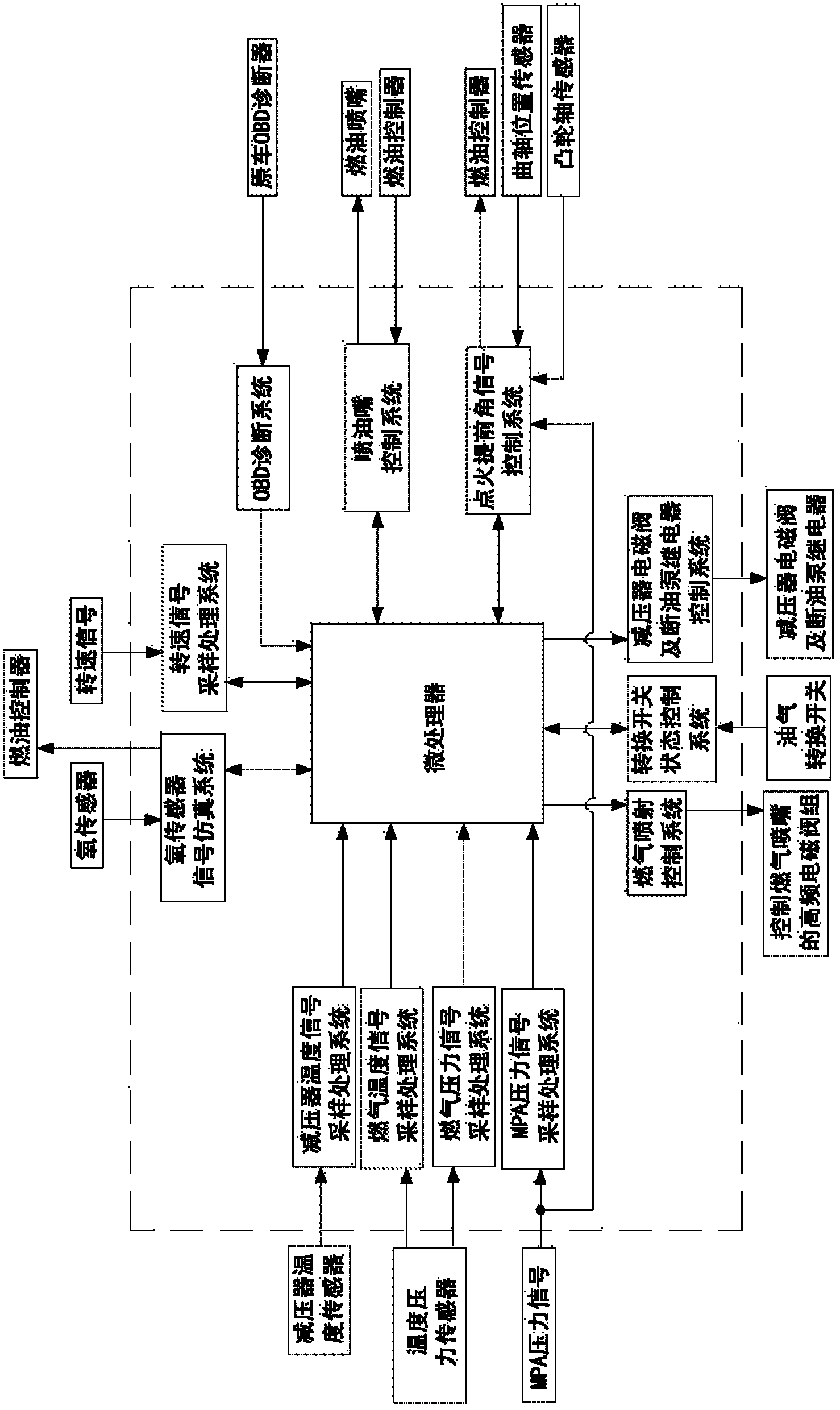

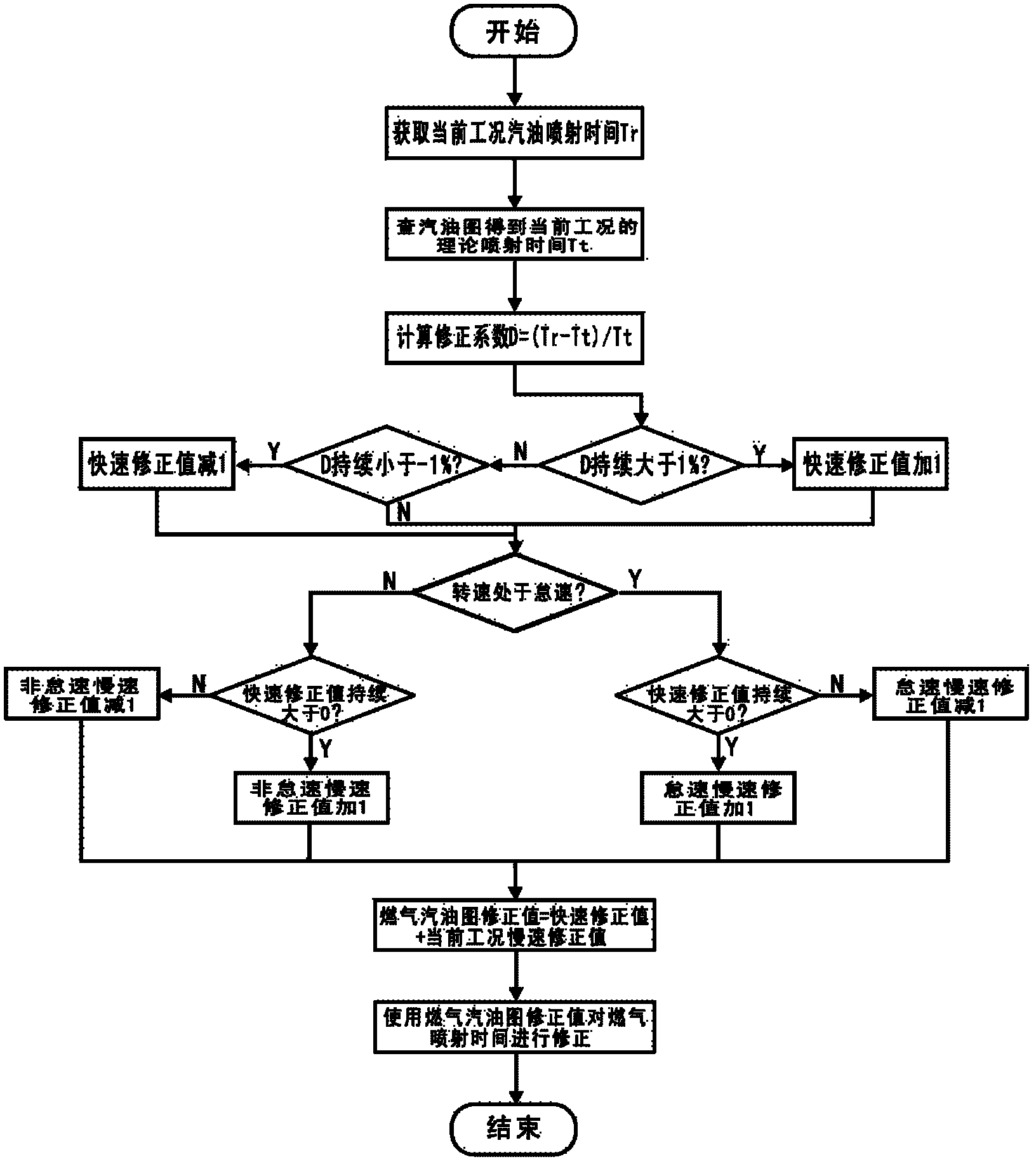

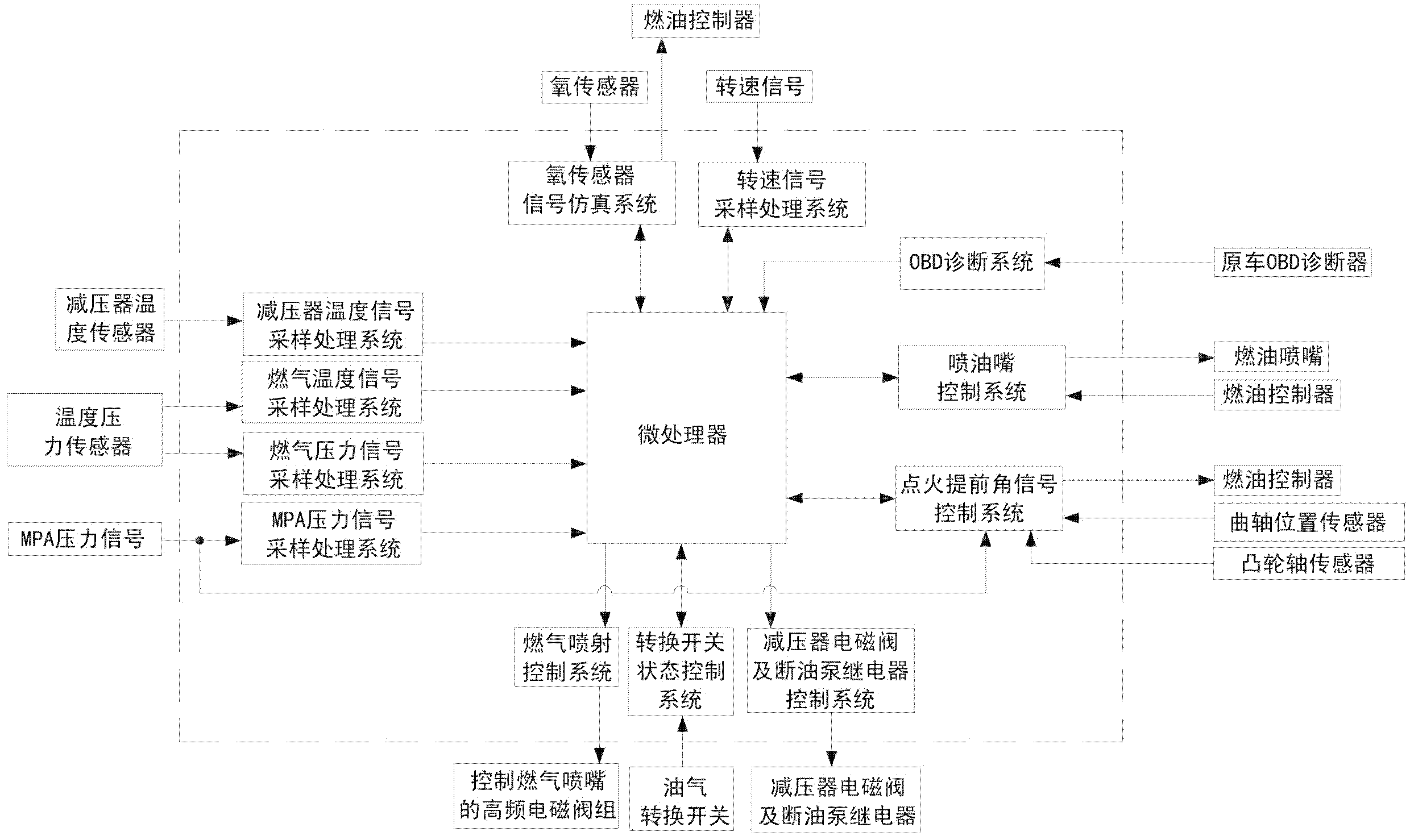

[0031] Such as figure 1Said: The dual-purpose fuel vehicle integrated gas controller of the present invention includes a microprocessor, a gas injection control system, a transfer switch state control system, a pressure reducer solenoid valve and a fuel pump relay control system, and an ignition advance angle signal control system , fuel injector control system, speed signal sampling and processing system, crankshaft position sensor and camshaft sensor, pressure reducer temperature signal sampling and processing system, gas pressure signal sampling and processing system, gas temperature sampling and processing system, MPA pressure signal sampling and processing system, Oxygen sensor signal simulation system, OBD diagnosis system, decompression temperature sensor, temperature pressure sensor, MPA pressure signal sampling and processing system, high-frequency solenoid valve g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com