Sample treatment method in measurement of calcium content of industrial silicon

A technology for sample processing and industrial silicon, which is used in the preparation of test samples and the measurement of color/spectral characteristics. It can solve the problems of inaccurate data, unstable calcium color rendering, large deviation, etc. Stable, small deviation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

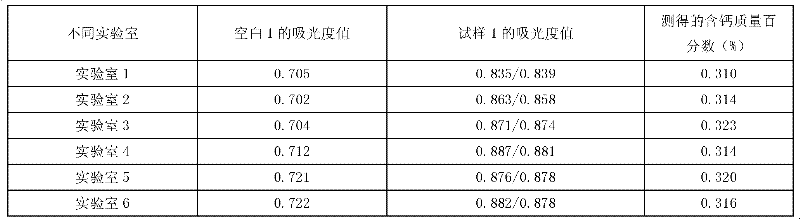

[0011] According to the following method, in different laboratories, let different analysts determine the calcium content of the standard sample with a calcium content of 0.315% by mass:

[0012] 1. Weigh 0.1g of industrial silicon sample, add 5ml of hydrofluoric acid to the sample, then slowly add 3ml of nitric acid dropwise, heat until the industrial silicon sample dissolves, keep the heating state at 80-90°C and add 2ml of nitric acid again, Stop heating after the nitric acid fumes are exhausted, then add 10ml of hydrochloric acid aqueous solution and heat to dissolve the salts to obtain mixture 1. After the mixture 1 is cooled, make up the mixture 1 to 100ml with water, so that the final concentration of the industrial silicon sample is 1mg / ml. Obtain sample liquid 1, the volume percent of hydrochloric acid in hydrochloric acid aqueous solution is 25%;

[0013] 2. Take 5ml of sample solution 1, add 5ml of triethanolamine aqueous solution, the volume percentage of triethano...

Embodiment 2

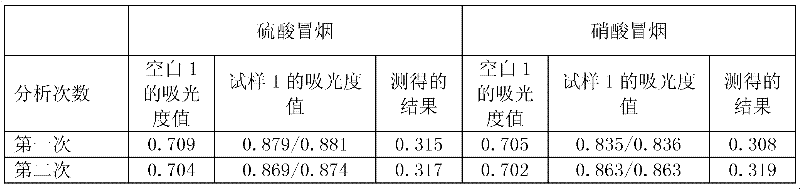

[0019] According to the following method, in different laboratories, let different analysts determine the calcium content of the standard sample with a calcium content of 0.315% by mass:

[0020] 1. Weigh 0.5g of industrial silicon sample, add 5ml of hydrofluoric acid to the sample, then slowly add 5ml of nitric acid dropwise, heat until the industrial silicon sample dissolves, then add 2ml of nitric acid again while heating, and wait for the nitric acid to smoke. After that, stop heating, then add 10ml of hydrochloric acid aqueous solution and heat to dissolve the salts to obtain a mixture 1. After the mixture 1 is cooled, make up the mixture 1 to 100ml with water, so that the final concentration of the industrial silicon sample is 5mg / ml, and the sample solution 1 is obtained. , the volume percent of hydrochloric acid in the hydrochloric acid aqueous solution is 27%;

[0021] 2. Take 5ml of sample solution 1, add 5ml of triethanolamine aqueous solution, the volume percentage...

Embodiment 3

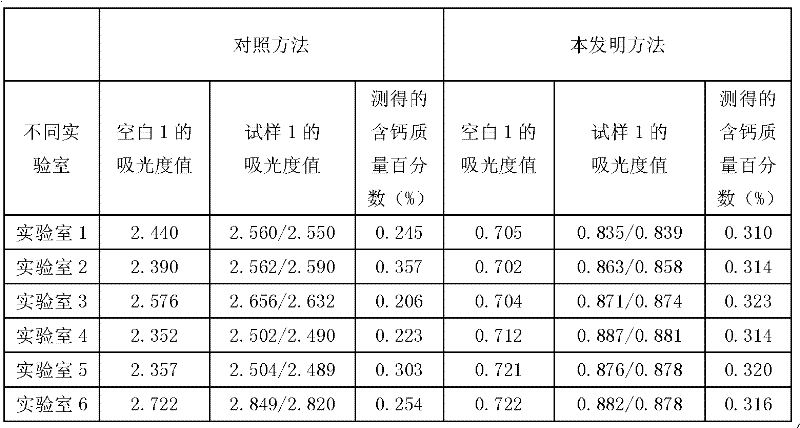

[0026] The contrast of embodiment 3 different sample processing methods

[0027] Using GB / T14849.3-2007 "Chlorophosphine Azo I Spectrophotometric Determination of Calcium Content" 16.4.1-16.4.6 as a contrast method, compared with the sample processing method during the determination of calcium content in industrial silicon of the present invention, the work The drawing of curve and data processing are the same as steps 3 and 4 in embodiment 1, and the standard sample of calcium content 0.315% by mass is analyzed and compared, and the results are as follows:

[0028]

[0029] As can be seen from the above table: the calcium content mass percentage measured by the control method is unstable, the standard deviation is 0.056%, and the deviation with the actual calcium content is also large, the average calcium content of the 6 groups of data is different from the actual The absolute deviation of the calcium content is 0.05%; adopt the sample processing method during the determi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap