Water-soluble graphene used for super capacitor electrode material and preparation method thereof

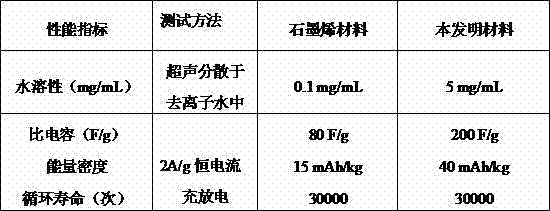

A technology for supercapacitors and electrode materials, applied in the direction of hybrid capacitor electrodes, capacitors, electrolytic capacitors, etc., to achieve the effect of improving electrochemical performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] According to the method reported in the literature, single-layer or multi-layer graphite oxide was prepared by chemical oxidation using natural graphite (Composites Science and Technology 2009, 69, 1231);

[0027] Take 100 mg graphite oxide, 100 mg ethylenediamine, 150 mg 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and 150 mg 4-dimethylaminopyridine after ultrasonic dispersion for 30 min , reacted at 20°C for 48h; after the reaction was completed, the mixed solution was cooled to room temperature, vacuum filtered, washed with deionized water, and vacuum-dried at 40°C for 24 h to obtain ethylenediamine-grafted graphene oxide;

[0028] The graphene oxide grafted by the resulting reaction product ethylenediamine was added in 150 mg 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, 150 mg 4-dimethylaminopyridine and 100 g of unpurified acrylic acid mixture was ultrasonically dispersed for 15 min, and then reacted at 20 °C for 48 h with stirring....

Embodiment 2

[0032] Take 100 mg graphite oxide, 500 mg ethylenediamine, 750 mg 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and 750 mg 4-dimethylaminopyridine and ultrasonically disperse for 30 min Finally, react at 100°C for 2 h; after the reaction is completed, the mixed solution is cooled to room temperature, vacuum filtered, washed with deionized water, and vacuum-dried at 100°C for 2 h.

[0033]The resulting reaction product was then mixed in 750 mg of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, 750 mg of 4-dimethylaminopyridine and 500 g of unpurified acrylic acid Ultrasonic dispersion was performed for 30 min, and then reacted at 100 °C for 2 h with stirring. The product was cooled, vacuum filtered, washed with deionized water, and dried in vacuum at 100 °C for 2 h to obtain vinyl-functionalized graphite oxide (GO-CH=CH 2 ).

[0034] The resulting vinyl functionalized graphite oxide (GO-CH=CH 2 ) and 500 mg of sodium styrene sulfonate were added to 5...

Embodiment 3

[0037] Take 1 g of graphite oxide, 1 g of ethylenediamine, 1.5 g of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride and 1.5 g of 4-dimethylaminopyridine after ultrasonic dispersion for 30 min , and reacted at 80°C for 4 h; after the reaction was completed, the mixed solution was cooled to room temperature and vacuum-filtered, washed with deionized water, and then vacuum-dried at 80°C for 6 h.

[0038] The resulting reaction product was then sonicated in 1.5 g of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride, 1.5 g of 4-dimethylaminopyridine and 1000 g of unpurified acrylic acid mixture Disperse for 30 min, then react for 4 h under stirring at 80 °C. The product was cooled, vacuum filtered, washed with deionized water, and dried in vacuum at 80 °C for 4 h to obtain vinyl-functionalized graphite oxide (GO-CH=CH 2 ).

[0039] The resulting vinyl functionalized graphite oxide (GO-CH=CH 2 ) and 1 g of sodium styrene sulfonate were added to 500 mL of deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com