Oral hydroxyl silk peptide nanoparticles and preparation method thereof

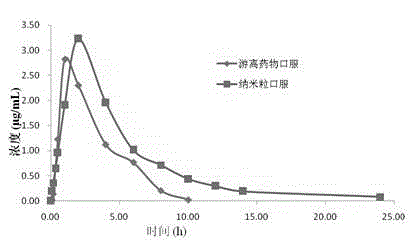

A nanoparticle, hydroxyl silk peptide technology, applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, digestive system, etc., can solve the problems of difficult to pass through the biofilm barrier, incomplete oral absorption, poor membrane permeability, etc., to achieve improved Bioavailability, promote gastrointestinal absorption, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

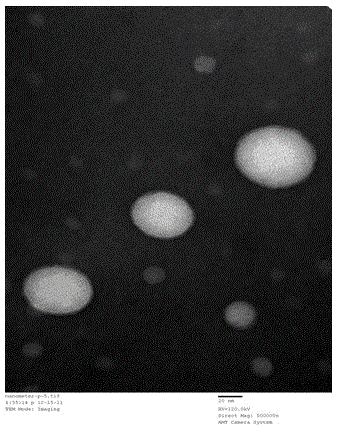

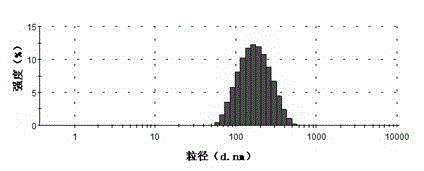

Image

Examples

Embodiment 1

[0025] a. Weigh 10mg of polyvinyl alcohol (PVA), dissolve it in 1ml of deionized water to obtain a PVA solution with a mass volume fraction of 1%, and dissolve 10mg of hydroxyl silk peptide in 0.5ml of the above PVA solution to form an inner water phase; Take 15 mg Tween 80 and 30 mg polyglycolide-lactide copolymer (PLGA, molecular weight 15000, purchased from Singma Company) and dissolve in 1.5 ml ethyl acetate to form an oil phase; take 0.2 ml of the inner water phase and 1.5 ml oil phase mixed, 100W ultrasonic emulsification for 30 sec, to obtain W / O colostrum;

[0026] b. Weigh 150mg of PVA, dissolve in 15ml of deionized water to form an external aqueous phase with a mass volume fraction of 1%; mix 12ml of external aqueous phase with 1.7ml of W / O colostrum obtained in step a, and ultrasonic emulsify at 100W for 60 sec , get W / O / W double milk;

[0027] c. Place the W / O / W double emulsion obtained in step b in a water bath at 40°C, and evaporate under reduced pressure to obt...

Embodiment 2

[0031] a. Weigh 20mg of polyvinyl alcohol (PVA), dissolve it in 1ml of deionized water to obtain a PVA solution with a mass volume fraction of 2%, and dissolve 30mg of hydroxyl silk peptide in 1ml of the above PVA solution to form an inner water phase; weigh 40mg of F68 and 40mg of polylactic acid (PLA, purchased from Jinan Daigang Bioengineering Company) were dissolved in 2ml of ethyl acetate to form an oil phase; 0.5ml of the inner water phase was mixed with 2ml of the oil phase, and ultrasonically emulsified at 200W for 1min to obtain W / O colostrum;

[0032] b. Weigh 300mg of PVA, dissolve it in 15ml of deionized water to form an external water phase with a mass volume fraction of 2%; mix 12ml of the external water phase with 2.5ml of the W / O colostrum obtained in step a, and ultrasonically emulsify at 100W for 2min. Get W / O / W double milk;

[0033] c. Put the W / O / W double emulsion obtained in step b in a water bath at 35°C, and evaporate under reduced pressure to obtain a...

Embodiment 3

[0037] a. Weigh 10mg of polyvinyl alcohol (PVA), dissolve it in 0.5ml of deionized water to obtain a PVA solution with a mass volume fraction of 2%, and dissolve 20mg of hydroxyl silk peptide in 0.5ml of the above PVA solution to form an inner water phase; Weigh 45mg F68 and 60 mg polyglycolide-lactide copolymer (PLGA, molecular weight 47000, purchased from Singma Company) and dissolve in 1.5ml ethyl acetate to form an oil phase; take 0.5ml internal water phase and 1.5ml The oil phase is mixed, 100W ultrasonic emulsification for 1.5min, and W / O colostrum is obtained;

[0038] b. Weigh 200mg of PVA and dissolve it in 20ml of deionized water to form an external aqueous phase with a mass volume fraction of 1%; mix 18ml of the external aqueous phase with 2ml of the W / O colostrum obtained in step a, and ultrasonic emulsify at 100W for 1min to obtain W / O / W complex milk;

[0039] c. Put the W / O / W double emulsion obtained in step b in a water bath at 45°C, and evaporate under reduced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com