Method for in-situ polymerization and modification of polyvinylidene fluoride microporous membrane

A technology of polyvinylidene fluoride and in-situ polymerization, applied in the field of membrane separation, can solve the problems of low water flux, low surface energy, membrane fouling, etc., and achieve the effect of simple preparation method, mild reaction conditions and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

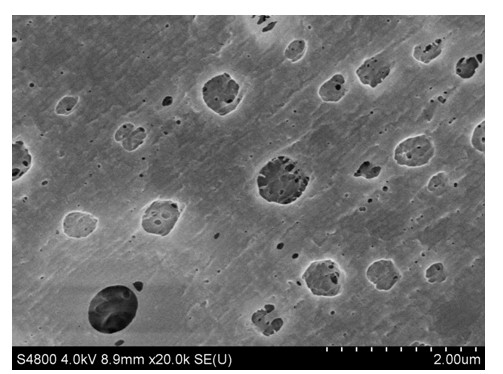

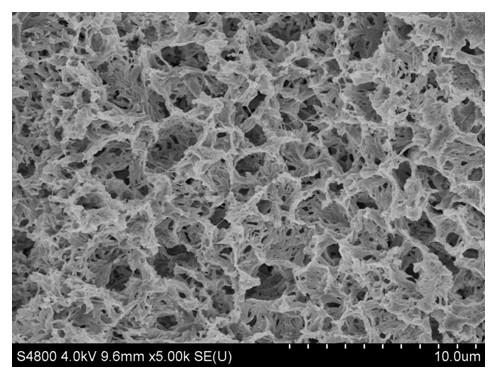

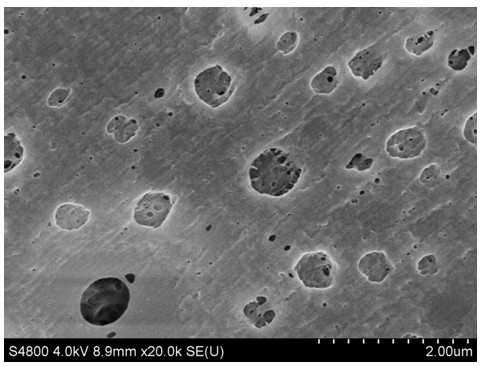

Image

Examples

Embodiment 1

[0022] Step (1). Dissolve 100 grams of polyvinylidene fluoride in 900 grams of triethyl phosphate, stir for 72 hours at 75 ° C, and the stirring speed is 100 rpm to make a film-forming precursor solution;

[0023] Step (2). Keep the stirring temperature and stirring speed constant, add 20 grams of active solution to the film-forming precursor solution under nitrogen protection to carry out in-situ polymerization reaction, after reacting for 48 hours, stop the nitrogen protection, and expose the reactant to the Terminate the reaction in the air, keep the reaction temperature constant for 36 hours, and obtain the casting solution after defoaming;

[0024] The components of the active solution are azobisisobutyronitrile, hydroxyethyl methacrylate and triethyl phosphate in a mass ratio of 1:150:130;

[0025] Step (3). The casting solution is processed by a film forming machine to form a primary film;

[0026] Step (4). The nascent film was directly immersed in a deionized water b...

Embodiment 2

[0030] Step (1). Dissolve 200 grams of polyvinylidene fluoride in 800 grams of triethyl phosphate, stir for 5 hours at 125 ° C, and the stirring speed is 1000 rpm to make a film-forming precursor solution;

[0031] Step (2). Keep the stirring temperature and stirring speed constant, add 300 grams of active solution into the film-forming precursor solution under the protection of nitrogen to carry out in-situ polymerization reaction, after reacting for 2 hours, stop the protection of nitrogen, and expose the reactant to the Terminate the reaction in the air, keep the reaction temperature constant for 18 hours, and obtain the casting solution after defoaming;

[0032] The components of the active solution are azobisisobutyronitrile, methyl methacrylate and triethyl phosphate in a mass ratio of 1:150:130;

[0033] Step (3). The casting solution is processed by a film forming machine to form a primary film;

[0034] Step (4). After the primary film is formed, immerse it in a coag...

Embodiment 3

[0037] Step (1). Dissolve 300 grams of polyvinylidene fluoride in 700 grams of triethyl phosphate, stir at 100 ° C for 24 hours, and the stirring speed is 600 rpm to make a film-forming precursor solution;

[0038] Step (2). Keep the stirring temperature and stirring speed constant, add 80 grams of active solution into the film-forming precursor solution under the protection of nitrogen to carry out in-situ polymerization reaction, after reacting for 36 hours, stop the protection of nitrogen, and expose the reactant to the Terminate the reaction in the air, keep the reaction temperature constant for 24 hours, and obtain the casting solution after defoaming;

[0039] The components of the active solution are azobisisobutyronitrile, hydroxypropyl methacrylate and triethyl phosphate in a mass ratio of 1:150:130;

[0040] Step (3). The casting solution is processed by a film forming machine to form a primary film;

[0041]Step (4). Immerse the primary film in a deionized water ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com