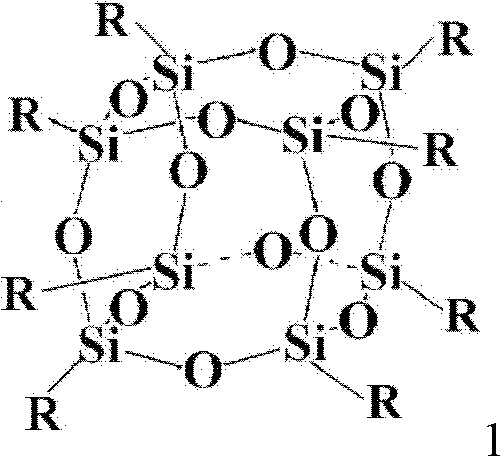

Preparation method of cage type n-propyl oligomeric silsesquioxane

A technology of polysilsesquioxane and propyltrimethoxysilane, applied in the direction of organic silicon compounds, etc., can solve the problems of difficult reaction control, complicated treatment process, a large amount of waste acid, etc., and achieves short preparation period and high yield. High and pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

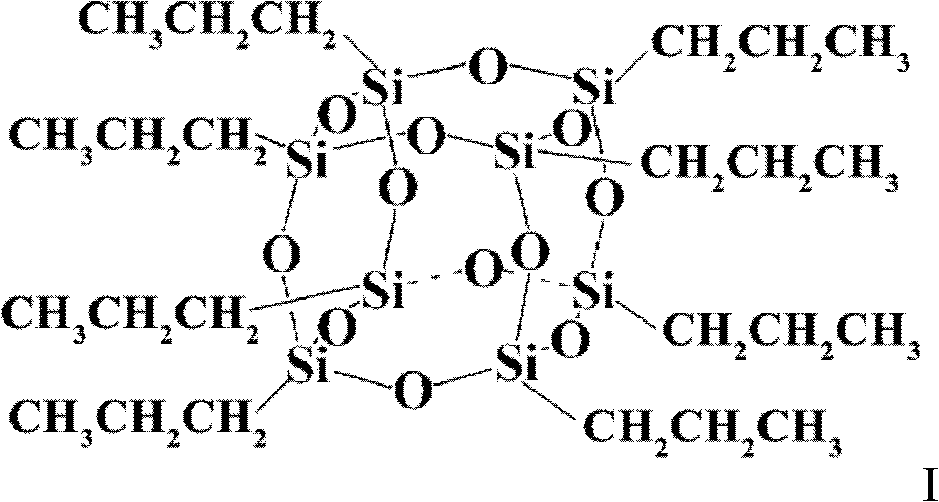

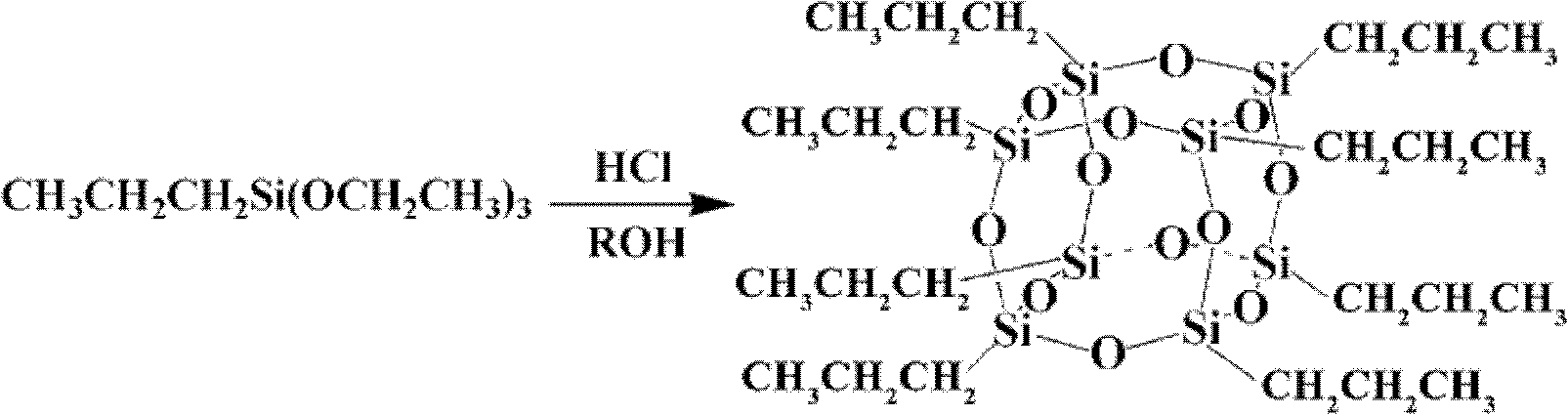

Embodiment 1

[0030] In a 1L grinding bottle, add 0.6L of ethanol, 56.0mL of concentrated hydrochloric acid (38wt%), and 50.0mL of n-propyltriethoxysilane in sequence, mix well, and seal the bottle. Control the temperature of the reaction solution at 0-5°C, let the system hydrolyze and condense for 96 hours under stirring conditions, remove the reaction solution by filtration to obtain a white powder solid, wash with methanol three times, and dry in a vacuum oven for 5.0 hours to obtain 15.1997 g products. The yield was 73.9%. Structure Characterization: 29 Si-NMR, -66.93ppm (CDCl 3 ); 1 H-NMR, 0.63ppm (t, Si-CH 2 -, 2H), 0.98ppm (t, -CH 3 , 3H) and 1.47ppm (m, -CH 2 -,2H)(CDCl 3 ); 13 C-NMR, 14.40ppm, 16.33ppm and 17.33ppm (CDCl 3 ); FTIR, 1114cm -1 (νSi-O-Si), 1220cm -1 (νSi-C), 2958cm -1 , 2930cm -1 and 2872cm -1 (ν C-H), 1464cm -1 and 1378cm -1 (δC-H); MS, [M] + =762.5925; single crystal diffraction, C 24 h 56 Si 8 o 12 , M=761.88, triclinic, space group P -1 , ...

Embodiment 2

[0032] In a 3L round bottom flask, add 1.6L of methanol, 200.0mL of concentrated hydrochloric acid (37%), and 150.0mL of n-propyltriethoxysilane in sequence, mix well, and seal the bottle. Control the temperature of the reaction solution at 0-5°C, let the system hydrolyze and condense for 120 hours under stirring conditions, and use the filtered reaction solution for later use to obtain a white powder solid, wash it with methanol three times, and dry it in a vacuum oven for 5 hours to obtain 43.9950g product. The yield was 71.3%, and the structural characterization of the product was as in Example 1.

Embodiment 3

[0034] In a 500mL ground-mouth Erlenmeyer flask, add 200mL of ethanol and 80.0mL of the filtered mother liquor in Example 1, 20.0mL of concentrated hydrochloric acid (36.5wt%), and 21.0mL of n-propyltrimethoxysilane, mix well, and seal bottle mouth. Control the temperature of the reaction solution at 0-5°C, let the system hydrolyze and condense for 80 hours under stirring conditions, remove the reaction solution by filtration to obtain a white powder solid, wash with methanol three times, and dry in a vacuum oven for 5 hours to obtain 9.4327g product. The yield was 83.2%, and the structural characterization of the product was as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com