Method for extracting chitin and antibacterial peptide from fly larvae

An antimicrobial peptide and chitin technology, applied in the field of natural product extraction, can solve problems such as demanding process conditions, high extraction costs, and poor environmental conditions, and achieve the effects of reasonable technical route, friendly production environment, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

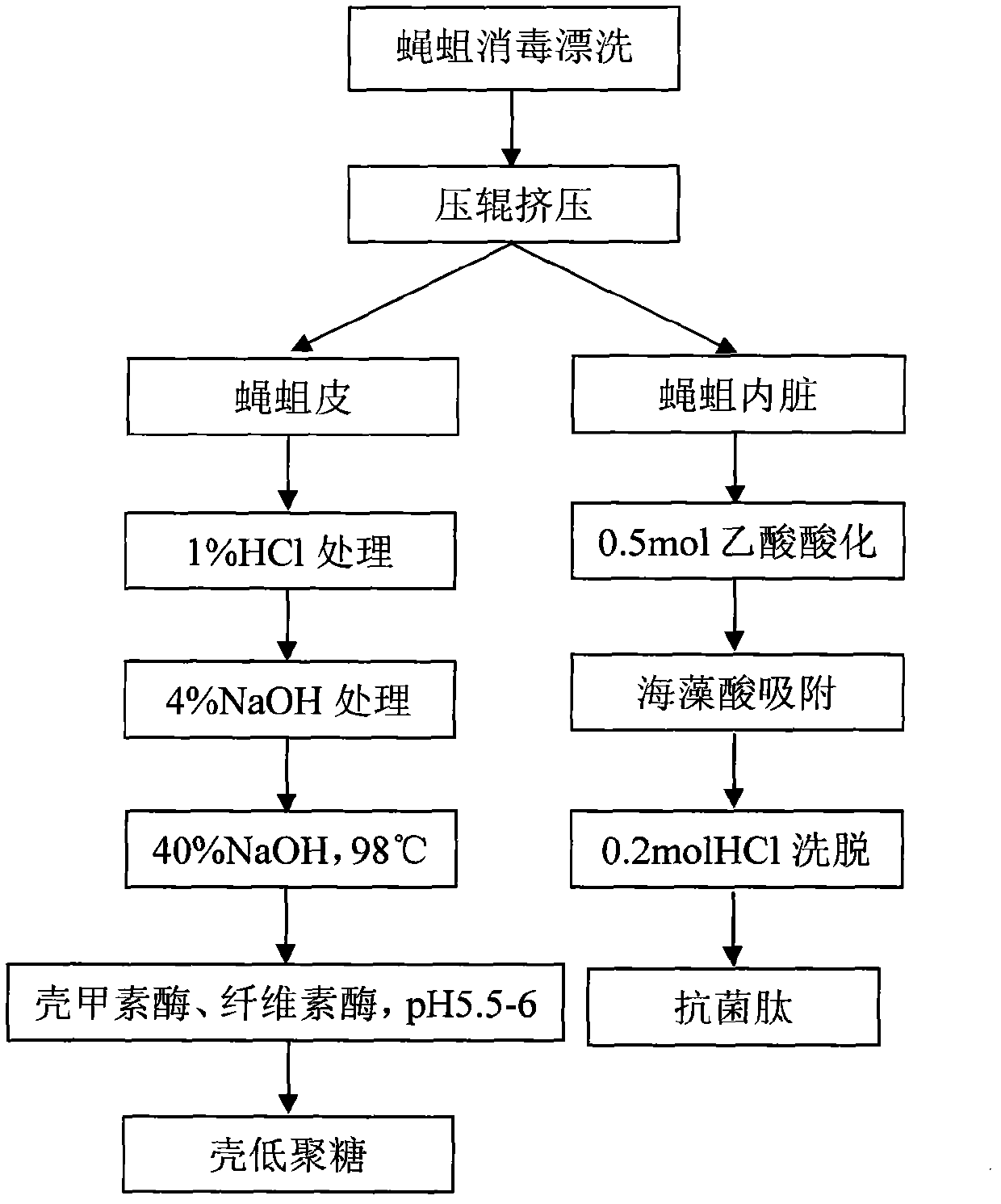

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Get feces to cultivate fly maggot 100g, use 1 / 5000KMnO 4 After rinsing the solution for 10 minutes, put 1 / 100 soybean meal pulp into it and cultivate it for 1 day, so that the fly maggots can drain the feces, and then wash once with clear water to obtain 91g of fresh fly maggots, which are squeezed by a roller to obtain 35g of fly maggot skin and maggot skin. Visceral pulp 56g, chitin and chitosan can be extracted from fly maggot skin, and antibacterial peptide can be extracted from fly maggot visceral pulp.

Embodiment 2

[0019] (1) Preparation of chitin: Add 35g of fly maggot skins to a 250ml three-neck flask, add 50ml of 1% hydrochloric acid solution, heat in a water bath at 38-40°C for 4 hours, filter, wash several times until neutral, dry at 50°C, and dry Add 50ml of 4% NaOH to the maggot skin, heat in a 96-98 water bath for 5 hours, filter, wash several times until neutral, and dry below 50°C to obtain 4.9g of chitin with a yield of 14%.

[0020] (2) Chitosan preparation: Soak chitin 4.9g in 100ml45%-55% NaOH, after continuing to react for 8 hours in a water bath at 98-99°C, prepare 100ml45%-55% NaOH again, Continue to heat in the water bath at 98-99°C for 8-16 hours. When the product is completely dissolved in 1%-2% acetic acid, the reaction is completed, and washed with water until neutral to obtain 3.4g chitosan, the yield is 70% of chitin. %.

[0021] (3) Preparation of chitooligosaccharides: Dissolve 3.4 g of fly maggot chitosan in 100 ml of acetic acid, adjust the pH to 5.5-6, add 4...

Embodiment 3

[0022] Example 3: Take 56g of fly maggot viscera mass slurry and add acetic acid to a concentration of 0.5mol / L, homogenize the slurry, overnight at 4°C, centrifuge, filter to obtain 200ml fly maggot antibacterial peptide acid extract, add alginic acid, and stir for 1 hour , so that the antimicrobial peptide is fully adsorbed by alginic acid, let it stand at 4°C overnight, and filter it with a Buchner funnel to collect the alginic acid that has adsorbed the antimicrobial peptide, elute it with 0.2mol / L hydrochloric acid, collect the eluate, and wash it with solid acetic acid After adjusting the pH value to 3.5 with sodium, salt it out with 320 g / L NaCl. After overnight, dialyze through a dialysis bag, desalt, and dry to obtain 0.6 g of crude antimicrobial peptide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com