Aromatic-aliphatic copolyester and synthetic method thereof

A technology of aliphatic copolyester and synthesis method, which is applied in the direction of adhesives, etc., can solve the problems of slow polymerization reaction speed, long reaction cycle, and many side reactions, and achieve less by-product generation, short polymerization reaction time, good heat The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] In a preferred embodiment, the synthetic method of the present invention comprises the following specific reaction steps:

[0015] 1) Esterification reaction. Will C 6 -C 10 Aromatic dicarboxylic acid, C 4 -C 12 Aliphatic dicarboxylic acids and C 2 -C 6 The aliphatic dihydric alcohol and the catalyst are added directly or made into a slurry into the reaction kettle, and the esterification reaction is carried out at a temperature of 140-240°C under normal pressure stirring, and the retort temperature is kept at 100±5°C. The progress of the esterification reaction is based on the water output. When the total water output reaches more than 98% of the theoretical water output, the esterification reaction is considered to be over.

[0016] C 6 -C 10 Aromatic dicarboxylic acids and C 4 -C 12 The molar ratio of the aliphatic dicarboxylic acid is 95:5-5:95, preferably 85:15-15:85, more preferably 70:30-30:70.

[0017] C 6 -C 10 Aromatic dicarboxylic acids and C 4 ...

Embodiment 1

[0052] Add 2565 grams of 1,4-butanediol (28.5 mol) and 18.4 grams of 1,2,3 glycerol (0.2 mol) into a 10L stainless steel reactor with a thermometer, mechanical stirrer, fractionating column and condenser , heating up, and then continue to add 1577 g of PTA (9.5 mol), 1919 g of 1,8-sebacic acid (9.5 mol) and 3 g of tetraethyl titanate under stirring. Heating to raise the temperature, when the temperature in the kettle reaches 160°C, the distillation temperature rises to 98-100°C, water begins to flow out, and the temperature continues to rise but the temperature does not exceed 230°C. When the water output reaches 99% of the theoretical amount, the esterification reaction ends. The entire esterification reaction took 4 hours. Add 2 grams of tetraethyl titanate and 3 grams of triphenyl phosphate into the reaction kettle, continue to heat up to 230-270 ° C, and perform a pre-condensation reaction for 1 hour to remove excess 1,4-butanediol. When the amount of 1,4-butanediol relea...

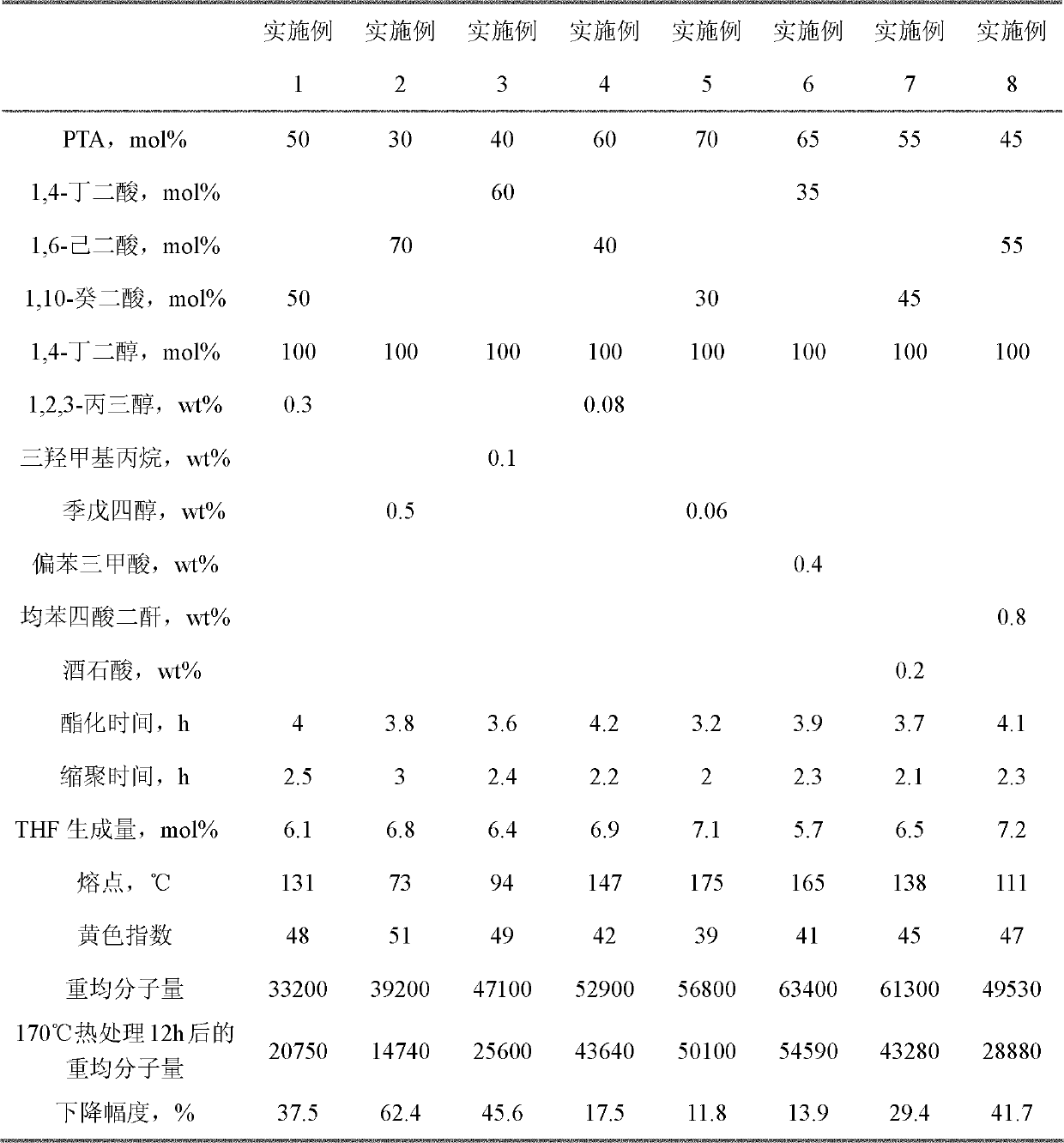

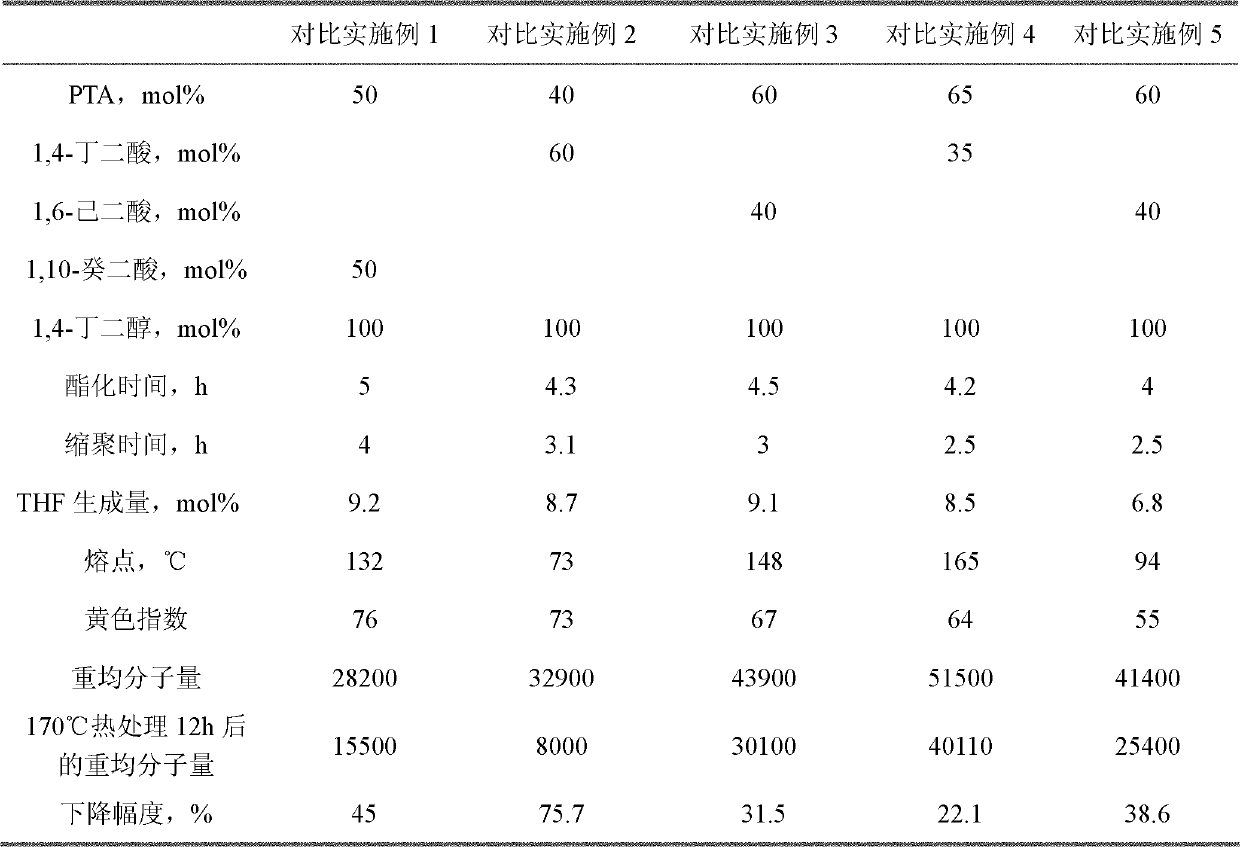

Embodiment 2-8

[0054] The above seven embodiments are carried out according to the steps and methods of Example 1, except that the raw materials and consumption are as shown in Table 1 below, and the analysis results of the products obtained are also listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com