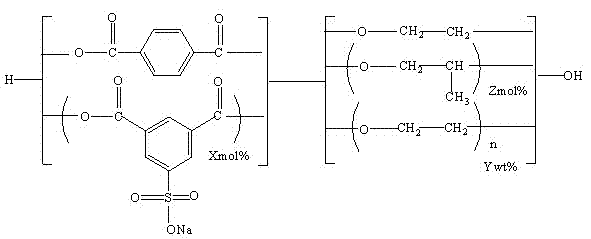

Hydrophilic copolyester chip and preparation method thereof

A copolyester, hydrophilic technology, applied in the field of polyester modification, can solve the problem of no obvious improvement in fiber moisture regain, and achieve the effects of good hydrophilic performance, easy industrial production and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

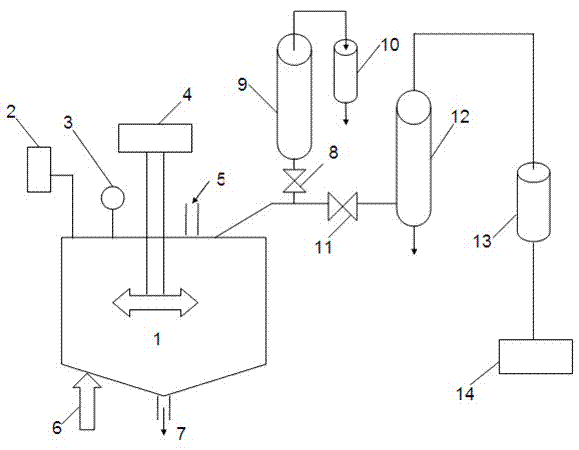

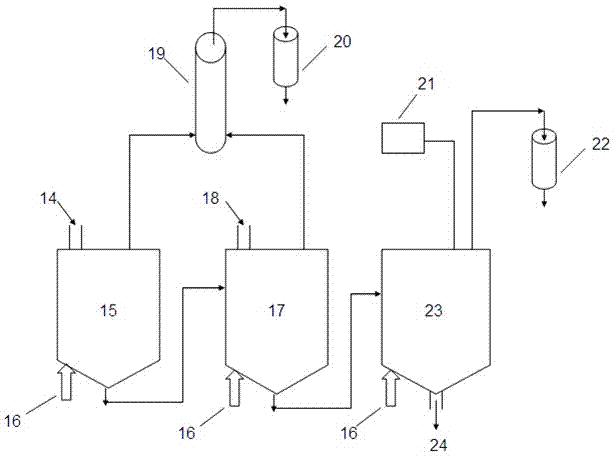

Method used

Image

Examples

Embodiment 1

[0082] Using batch polymerization equipment, add 10kg (60.24mol) PTA, 4.11kg (66.29mol) EG, 0.0916kg (1.204mol) 1,2-PDO, 0.3219kg (0.904mol) SIPE, 1kg (0.167mol) ) PEG6000, 0.05kg (0.626mol) TiO 2 , 0.003kg (0.01mol) of antimony acetate and 0.002kg (0.0061mol) of triphenyl phosphate were reacted for 3 hours at a reaction temperature of 245°C for esterification. The temperature of the reaction kettle 1 was set at 270° C., the vacuum degree was set at 15 Pa, the reaction was carried out for 3 hours, and the polycondensation reaction was carried out. After the reaction was completed, the material was discharged and pelletized to obtain copolyester chips. The chip had an intrinsic viscosity of 0.621 dL / g and a melting point of 244.2°C. After the prepared hydrophilic copolyester chips are pre-crystallized, dried and spun, a hydrophilic copolyester fiber is obtained, and the moisture regain of the fiber is 1.01%.

[0083]

Embodiment 2

[0085] Using batch polymerization equipment, add 10kg (60.24mol) PTA, 4.11kg (66.29mol) EG, 0.3664kg (4.816mol) 1,2-PDO, 1.2876kg (3.614mol) SIPE, 0.1kg (0.0167 mol) PEG6000, 0.2kg (2.504mol) TiO 2 , 0.003kg (0.01mol) of antimony acetate and 0.002kg (0.0061mol) of triphenyl phosphate were reacted for 3 hours at a reaction temperature of 245°C for esterification. The temperature of the reaction kettle 1 was set at 270° C., the vacuum degree was set at 15 Pa, the reaction was carried out for 3 hours, and the polycondensation reaction was carried out. After the reaction was completed, the material was discharged and pelletized to obtain copolyester chips. The chip had an intrinsic viscosity of 0.611 dL / g and a melting point of 241.1°C. After the prepared hydrophilic copolyester chips are pre-crystallized, dried and spun, a hydrophilic copolyester fiber is obtained, and the moisture regain of the fiber is 1.03%.

[0086]

Embodiment 3

[0088] Using batch polymerization equipment, add 10kg (60.24mol) PTA, 4.11kg (66.29mol) EG, 22.9kg (0.301mol) 1,2-PDO, 0.3219kg (0.904mol) SIPE, 3kg (0.501mol) ) PEG6000, 0.05kg (0.626mol) TiO 2 , 0.003kg (0.01mol) of antimony acetate and 0.002kg (0.0061mol) of triphenyl phosphate were reacted for 3 hours at a reaction temperature of 245°C for esterification. The temperature of the reaction kettle 1 was set at 270° C., the vacuum degree was set at 15 Pa, the reaction was carried out for 3 hours, and the polycondensation reaction was carried out. After the reaction was completed, the material was discharged and pelletized to obtain copolyester chips. The chip had an intrinsic viscosity of 0.56 dL / g and a melting point of 228.2°C. After the prepared hydrophilic copolyester chips are pre-crystallized, dried and spun, a hydrophilic copolyester fiber is obtained, and the moisture regain of the fiber is 1.80%.

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com