Poly 3,4-ethylenedioxy thiophene composite and preparation method thereof

A technology of dioxyethylene thiophene and composite materials, applied in the field of poly-3, to achieve the effects of low production cost, excellent cycle stability and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

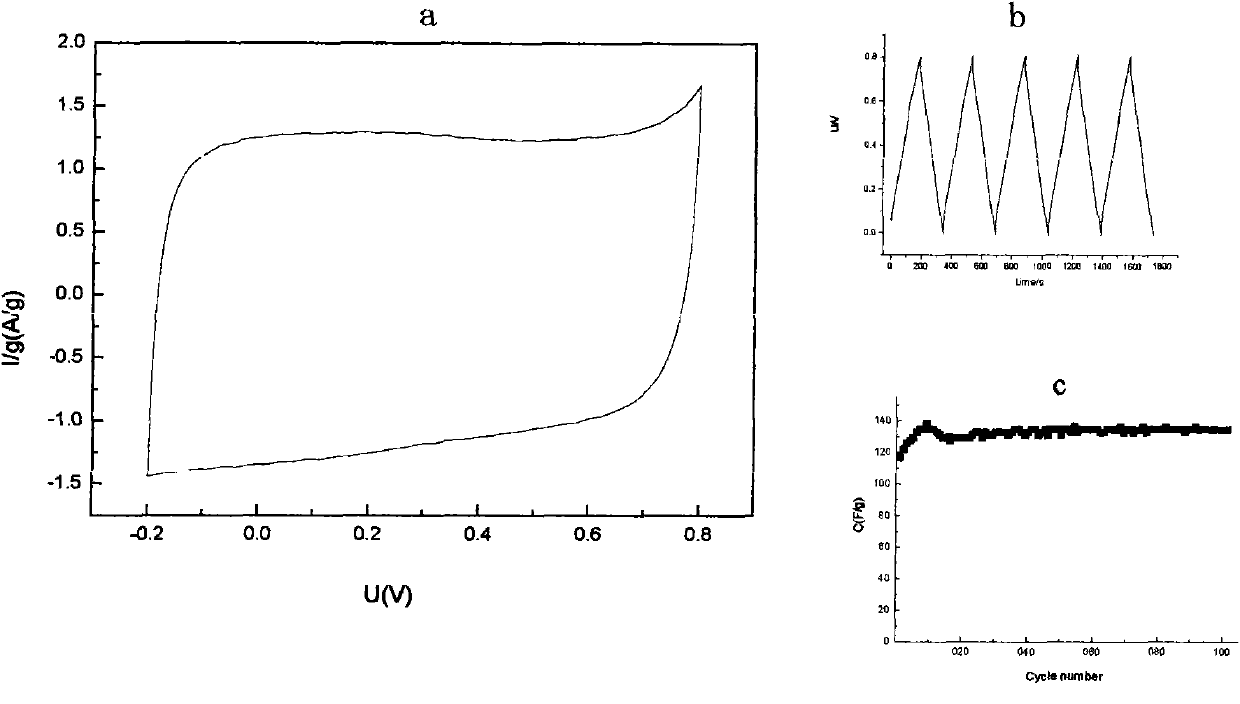

[0017] Dissolve 1 mole of sulfamic acid in distilled water to form a solution with a molar concentration of 0.5 mol / L, add 1 mole of 3,4-dioxyethylenethiophene, and stir until the two are evenly mixed to form a transparent emulsion; add 4L molar concentration 8mol / L FeCl 3 Aqueous solution, control the temperature of the system between 25-35 °C for 36 hours; pour the reaction solution into acetone, filter, wash the filter cake with 33% alcohol solution until the filtrate cannot change the color of phenol, wash the filter cake with distilled water, and dry it in vacuum. Grinding to obtain poly-3,4-dioxyethylenethiophene composite material doped with sulfamic acid.

[0018] Mix the prepared poly(3,4-dioxyethylenethiophene) composite material with conductive carbon black and 60wt% polytetrafluoroethylene emulsion in a mass ratio of 80:15:5, add an appropriate amount of absolute ethanol and ultrasonically vibrate until the mixture becomes a paste shape, the paste mixture was even...

Embodiment 2

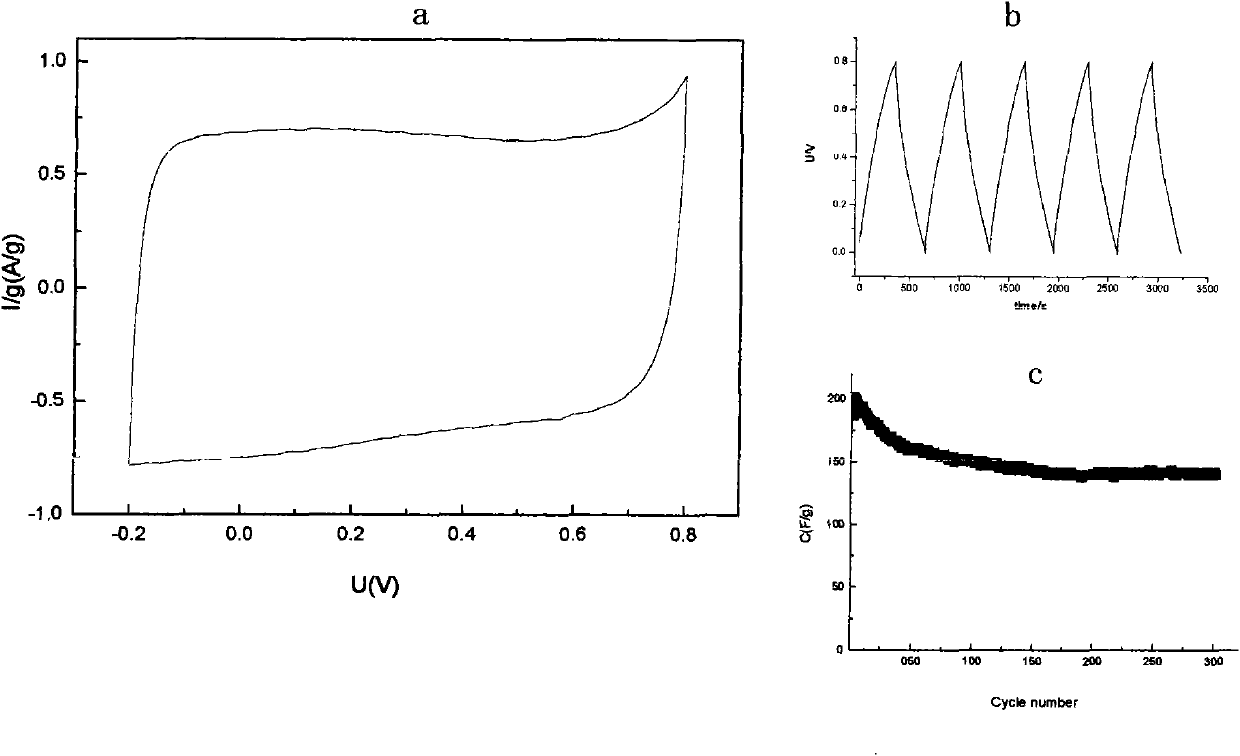

[0020] Dissolve 1 mole of camphorsulfonic acid in distilled water to form a solution with a molar concentration of 0.25 mol / L, add 2 moles of 3,4-dioxyethylenethiophene, and stir until the two are evenly mixed to form a transparent emulsion; add 2.5 L molar FeCl with a concentration of 8mol / L 3 Aqueous solution, control the temperature of the system between 25-35 °C for 41 hours; pour the reaction solution into acetone, filter, wash the filter cake with 33% alcohol solution until the filtrate cannot change the color of phenol, wash the filter cake with distilled water, and dry it in vacuum. Grinding to obtain camphorsulfonic acid-doped poly-3,4-dioxyethylenethiophene composite material.

[0021] The electrochemical performance test method is the same as in Example 1. The results show that the specific capacity of the obtained electrode material is 150F / g, and the charge-discharge efficiency is 94%.

Embodiment 3

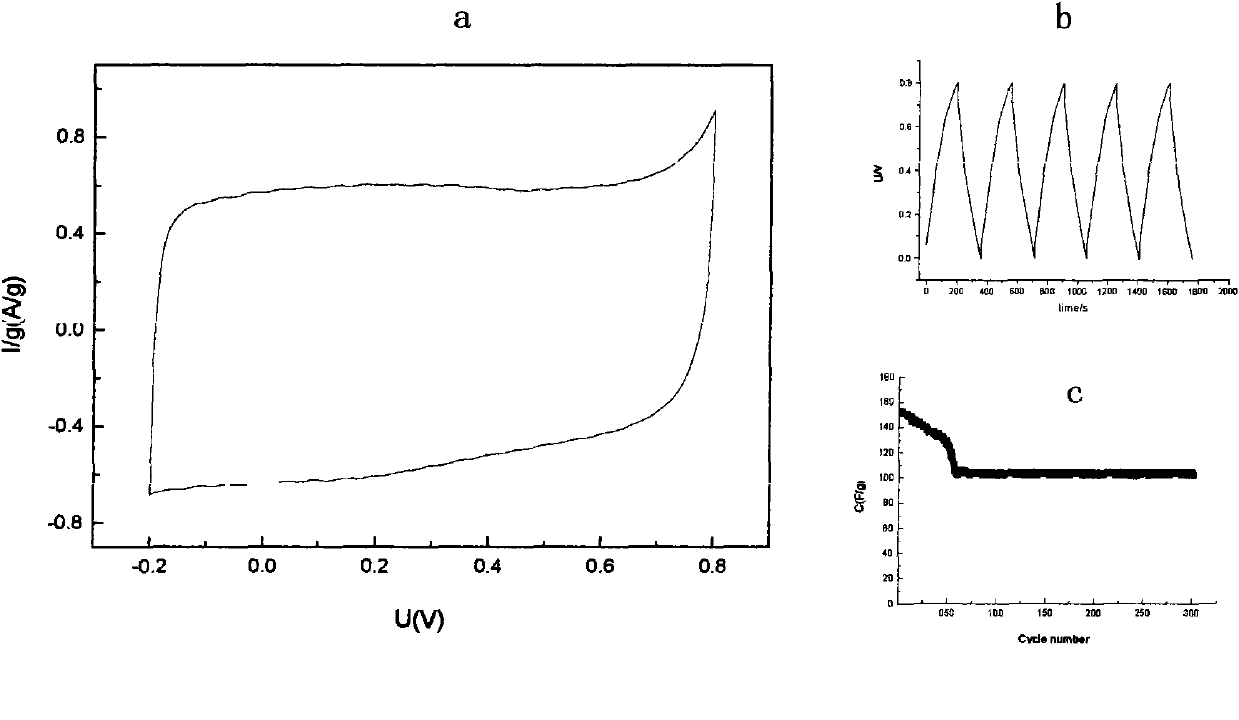

[0023] Dissolve 0.25 mole of sodium isethionate and 1 mole (according to sulfonate) of sodium polystyrene sulfonate in distilled water to form a solution with a molar concentration of 0.045 mol / L, and add 1 mole of 3,4-bis Oxyethylenethiophene, stir until the two are mixed evenly to form a transparent emulsion; add 5L of FeCl with a molar concentration of 10mmol / L 3 React with a mixed aqueous solution of potassium persulfate with a molar concentration of 0.3mol / L, and control the system temperature between 25-35°C for 36 hours; pour the reaction solution into acetone, filter, and wash the filter cake with 33% alcohol solution to the filtrate The phenol cannot be discolored, the filter cake is washed with distilled water, dried in vacuum, and ground to obtain a poly-3,4-dioxyethylenethiophene composite material doped with isethionic acid and polystyrene sulfonic acid.

[0024] The electrochemical performance test method is the same as in Example 1. The results show that the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com