Thin film photo-bioreactor used for culturing microalgae in industrialization manner

A technology of photobioreactor and reactor, which is applied in the direction of photobioreactor, specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, etc., which can solve pollution, high harvesting cost, algae cell Problems such as low cultivation density can achieve the effect of reducing exhaust gas emissions and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

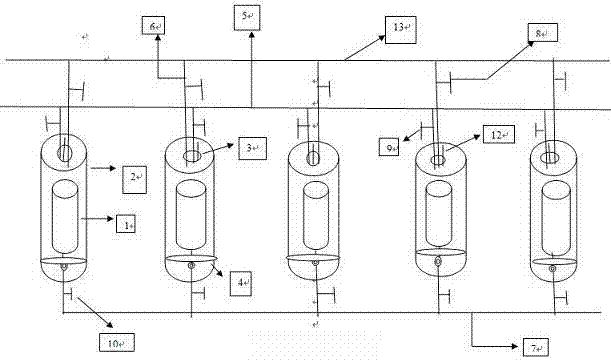

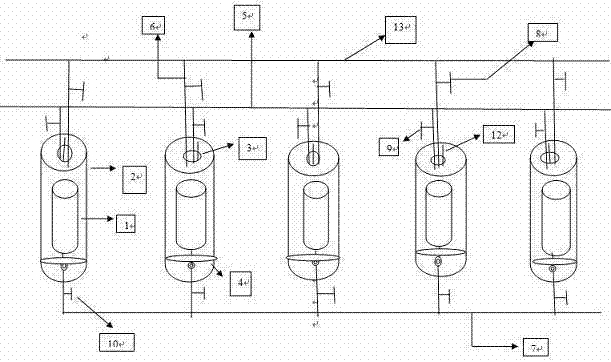

[0011] A thin-film photobioreactor for industrialized cultivation of microalgae, comprising a polypropylene (PP) film 1, a metal support 13 and its base 4, a sample inlet passage 5 of the reactor, and a CO of the reactor. 2 Air supply passage 6, gas discharge passage 12, reactor algae liquid collection passage 7, it is characterized in that: vertically placed polypropylene (PP) film 1 is placed in the reaction vessel as algae liquid cultivation in metal jacket 2, it is placed In the open vertically placed metal bracket 13, the lower end of the polypropylene (PP) film 1 is open, and connected with a threaded conduit, the conduit and the polypropylene (PP) film 1 are an airtight structure, and the base 4 has a The opening is an algae liquid collection outlet connected to the algae liquid collection channel 7 of the reactor. The opening is a threaded structure that can be tightly connected to the opening at the lower end of the film. 2 The gas supply passage 6 and the gas disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com