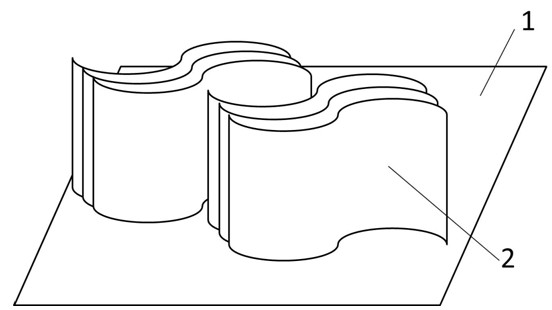

Super-capacitor electrode based on vertical oriented graphene and manufacturing method thereof

A supercapacitor, vertical orientation technology, applied in the direction of capacitors, electrolytic capacitors, circuits, etc., can solve the problems of complicated process and difficult promotion, so as to improve the speed of adsorption and desorption, reduce negative effects, and avoid the use of binders Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

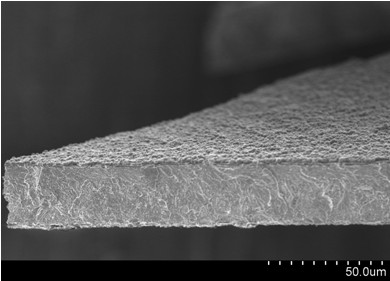

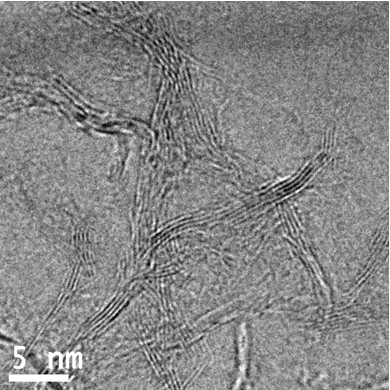

[0029] Example 1: A stainless steel sheet is used as a current collector, and a normal pressure normal glow discharge plasma-enhanced vapor deposition technique is used to manufacture a supercapacitor electrode with vertically oriented graphene as an active material.

[0030] A 0.025 mm stainless steel sheet and a needle tip with a taper of 1:10 are placed in a quartz tube, and the quartz tube is placed in a heating furnace. The needle tip is perpendicular to the surface of the stainless steel sheet, and the distance between the needle tip and the stainless steel sheet is 7 mm. The stainless steel sheet is grounded, and the needle tip is connected to a high-voltage negative power supply. A mixed gas of hydrogen and argon is introduced into the quartz tube (total flow rate: 2000 ml / min; volume ratio: 1:1), and the stainless steel sheet is heated to 700 oc. On hold at 700 o Under the premise of C heating, the mixed gas of hydrogen and argon is closed, and the mixed gas of arg...

Embodiment 2

[0031] Example 2: Using nickel foam as a current collector, the normal pressure normal glow discharge plasma enhanced vapor deposition technology is used to fabricate a supercapacitor electrode with vertically oriented graphene as an active material.

[0032] Place nickel foam and a needle tip with a taper of 1:10 in the quartz tube, and the quartz tube is placed in the heating furnace. The needle tip is perpendicular to the surface of the stainless steel sheet, and the distance between the needle tip and the stainless steel sheet is 7 mm. The nickel foam is grounded, and the needle tip is connected to a high-voltage negative power supply. A mixed gas of hydrogen and argon is introduced into the quartz tube (total flow rate: 2000 ml / min; volume ratio: 1:1), and the stainless steel sheet is heated to 1000 by a heating furnace o c. In keeping 1000 o Under the premise of C heating, the mixed gas of hydrogen and argon is closed, and the mixed gas of argon, acetylene and water v...

Embodiment 3

[0033] Example 3: Using copper sheets as current collectors, microwave plasma enhanced vapor deposition technology was used to manufacture supercapacitor electrodes with vertically oriented graphene as active materials.

[0034] Place the copper sheet inside the microwave plasma reactor. The plasma reactor was pumped down to 100 Pa. Turn on the microwave plasma reactor and adjust the input power to 600 watts to heat the copper sheet to 600 o c. After 10 minutes, a mixed gas of methane and hydrogen was introduced (total flow rate: 200 ml / min; volume ratio: 10:1), and the microwave plasma input power was adjusted to 800 watts. After 20 minutes, turn off the microwave plasma power supply, turn off methane and hydrogen at the same time, and at the same time pass in a mixture of hydrogen and argon (total flow rate: 200 ml / min; volume ratio: 1:1), and cool down naturally. When the temperature is below 50 o At C, turn off the mixed gas of hydrogen and argon, take out the sample, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com