Organic solar cell doped with phosphorescent dye

A technology of solar cells and phosphorescent dyes, applied in the field of solar cells, which can solve the problems of difficulty in precise control of concentration, energy consumption, single selection of small molecule donor materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

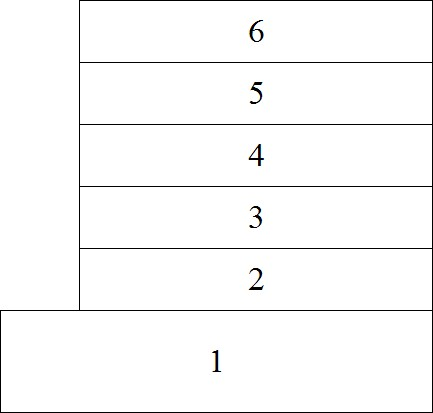

[0028] Schematic diagram of the structure of phosphorescent dye-doped organic solar cells. figure 1 As shown, on a glass substrate 1 are an anode 2 , a hole transport layer 3 , a donor layer 4 , an acceptor layer 5 , and a cathode 6 in sequence. The detailed preparation process is as follows:

[0029] a) Anode 2 is ITO. First, use chloroform cotton balls to repeatedly scrub, then put the scrubbed ITO into a clean beaker, and then use acetone, lye, deionized water, and ethanol to sonicate for 10 minutes, and then blow dry with a nitrogen gun.

[0030] b) Preparation of the hole transport layer 3. PEDOT:PSS was spin-coated on the surface of ITO at a speed of 2000rpm, and then dried in a vacuum oven at 120°C for 30 minutes, with a thickness of 40nm.

[0031] c1) Configure mixed solvent: add chlorobenzene to chloroform, the volume ratio of chloroform to chlorobenzene is 100:5, the purpose is to increase the uniformity of film thickness and change the surface morphology of the fi...

Embodiment 2

[0050] Compared with Example 1, the phosphorescent dye Ir(piq) is mixed in the donor layer 4 in Example 2 2 Acac, its molecular structure is as follows:

[0051] .

[0052] The preparation process is similar to Example 1, and the structure of the prepared organic solar cell (device 3) is:

[0053] Glass / ITO(180 nm) / PEDOT:PSS(40 nm) / MEH-PPV:5wt%Ir(piq) 2 acac (25nm) / C 70 (30 nm) / Al (150 nm).

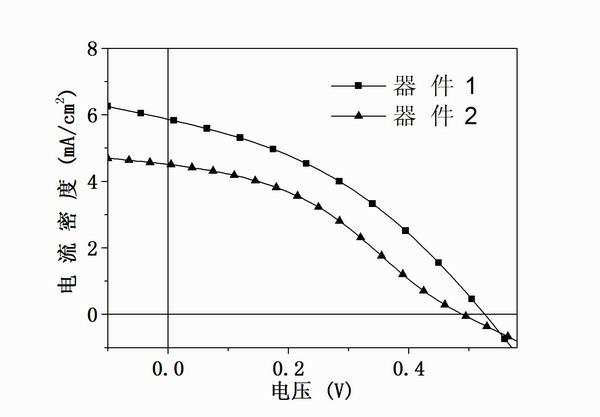

[0054] The maximum short-circuit current density of device 3 is 4.54 mA / cm 2 , the open circuit voltage is 0.46V, and the fill factor FF remains basically unchanged.

Embodiment 3

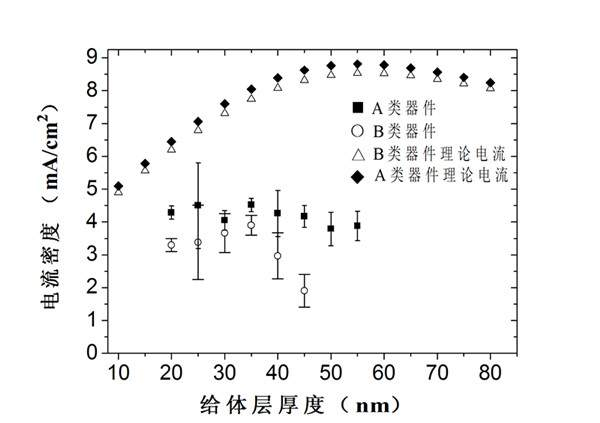

[0056] Compared with Example 1, the difference is that in the donor layer 4, the mass ratio of the polymer material to the phosphorescent dye is 100:3, and the performance of the prepared organic solar cell is:

[0057] The maximum short-circuit current density of the device is 4.56 mA / cm 2 , the open circuit voltage is 0.53V, and the fill factor FF remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com