Polyamine-modified chitosan base expanded bed adsorbing medium and preparation method thereof

An expanded bed adsorption, chitosan technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of high price and narrow flow rate operating range, and achieve improved adsorption efficiency, promote large-scale separation and purification, improve adsorption separation efficiency and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

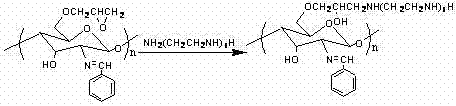

Method used

Image

Examples

Embodiment 1

[0020] Mix 100ml of chitosan solution with a mass fraction of 5% with 20g of stainless steel powder and 3g of PEG2000, then add 100ml of liquid paraffin, 15 drops of span-80, stir at high speed for 30min to make the system into an emulsion, then add 11ml of formaldehyde, and stir for 1h Pour the emulsion into a mixture of 10% NaOH / dehydrated ethanol (V(NaOH):V(dehydrated ethanol)=1:1) and let it stand for 1h, then wash it thoroughly with xylene, dehydrated ethanol and deionized water. Sieve to obtain chitosan / stainless steel powder composite microspheres with a particle size of 50-300 μm as a matrix; mix the drained composite microspheres, 50ml methanol, and 5ml benzaldehyde, react in a shaker at 200rpm at 60°C for 12h, and then add boron React sodium cyanide at room temperature for 12 hours, suction filter, and wash to obtain benzaldehyde substrate; then mix benzaldehyde substrate, 100ml 0.4mol / L NaOH solution, and 40ml epichlorohydrin, react at 50°C for 4 hours, suction filte...

Embodiment 2

[0022] Mix 100ml of chitosan solution with a mass fraction of 5% with 35g of stainless steel powder and 3g of PEG2000, then add 100ml of liquid paraffin, 15 drops of span-80, stir at high speed for 30min to make the system into an emulsion, then add 11ml of formaldehyde, and stir for 1h Pour the emulsion into a mixture of 10% NaOH / dehydrated ethanol (V(NaOH):V(dehydrated ethanol)=1:1) and let it stand for 2 hours, then wash it thoroughly with xylene, dehydrated ethanol and deionized water. Sieve to obtain chitosan / stainless steel powder composite microspheres with a particle size of 50-300 μm as the matrix; mix the drained composite microspheres, 50ml methanol, and 5ml benzaldehyde, react in a shaker at 200rpm at 60°C for 8h, and then add boron React sodium cyanide at room temperature for 12 hours, suction filter, and wash to obtain benzaldehyde substrate; then mix benzaldehyde substrate, 100ml 0.4mol / L NaOH solution, and 25ml epichlorohydrin, react at 50°C for 4 hours, suction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com